Zinc ion battery and manufacturing method thereof

A zinc ion battery and anion technology, applied in the field of materials, can solve the problems of zinc ion battery to be improved, narrow electrochemical window, and high freezing point.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

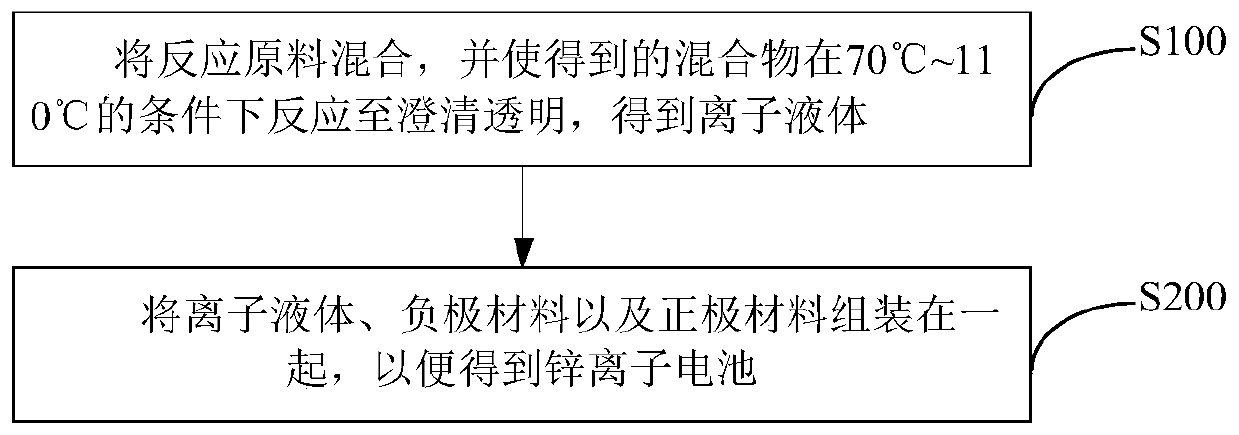

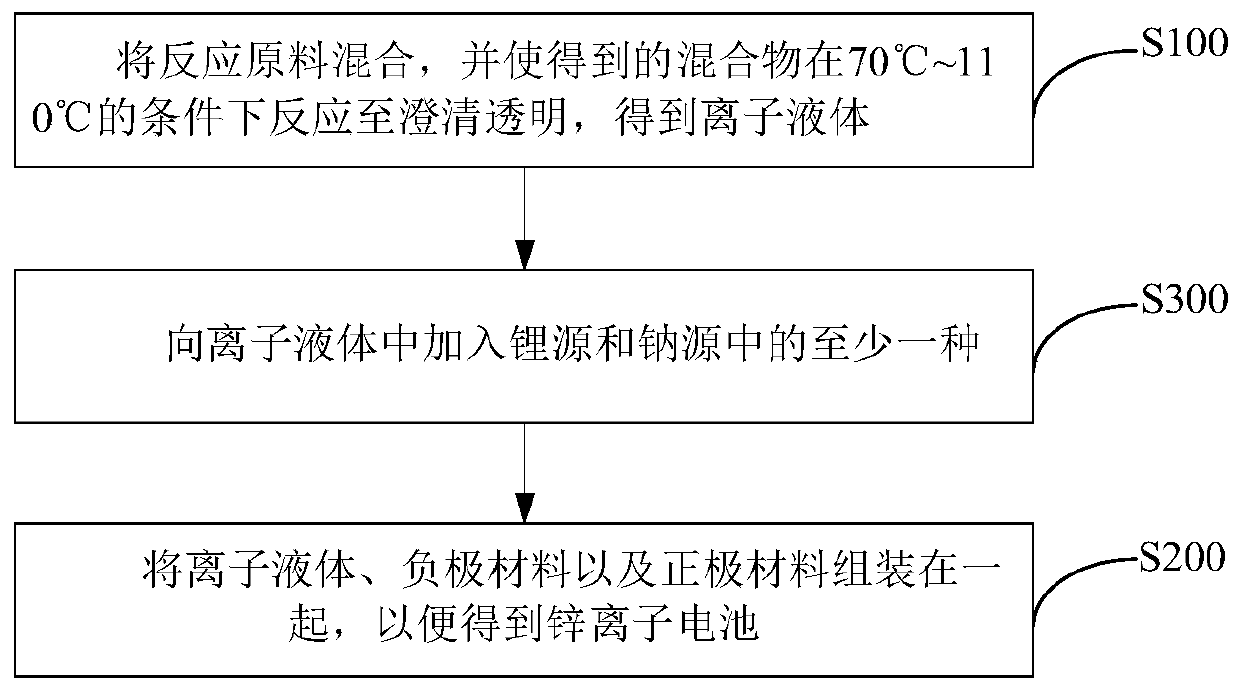

Method used

Image

Examples

Embodiment 1

[0060] Put the urea in a vacuum drying oven at 60°C for 12 hours, and cool it for later use; add ZnCl 2 Dry in a vacuum oven at 200°C for 3 hours, then cool for later use. Then ZnCl 2 Mix it with urea at a molar ratio of 1:3 and place it in a three-necked flask, heat and stir at 90°C to make it molten and clear. After the ionic liquid is cooled, measure the volume of the liquid with a graduated cylinder, and weigh it according to the volume of the liquid. A certain mass of NaCl makes the NaCl concentration 1.5mol / L. Finally, the aforementioned liquid and NaCl were added into the three-necked flask, and reheated to 90° C. to obtain the ionic liquid.

[0061] Battery assembly: positive pole MnO 2 or ZnMn 2 o 4 ; the negative pole is zinc foil or zinc powder made by drawing copper net current collector; the diaphragm is PP diaphragm or AGM diaphragm, specifically, after the diaphragm is fully soaked in the ionic liquid electrolyte, it is combined with the positive electrode ...

Embodiment 2

[0070] Others are the same as in Example 1, except that the molar ratio of ZnCl2 to urea is 1:2.

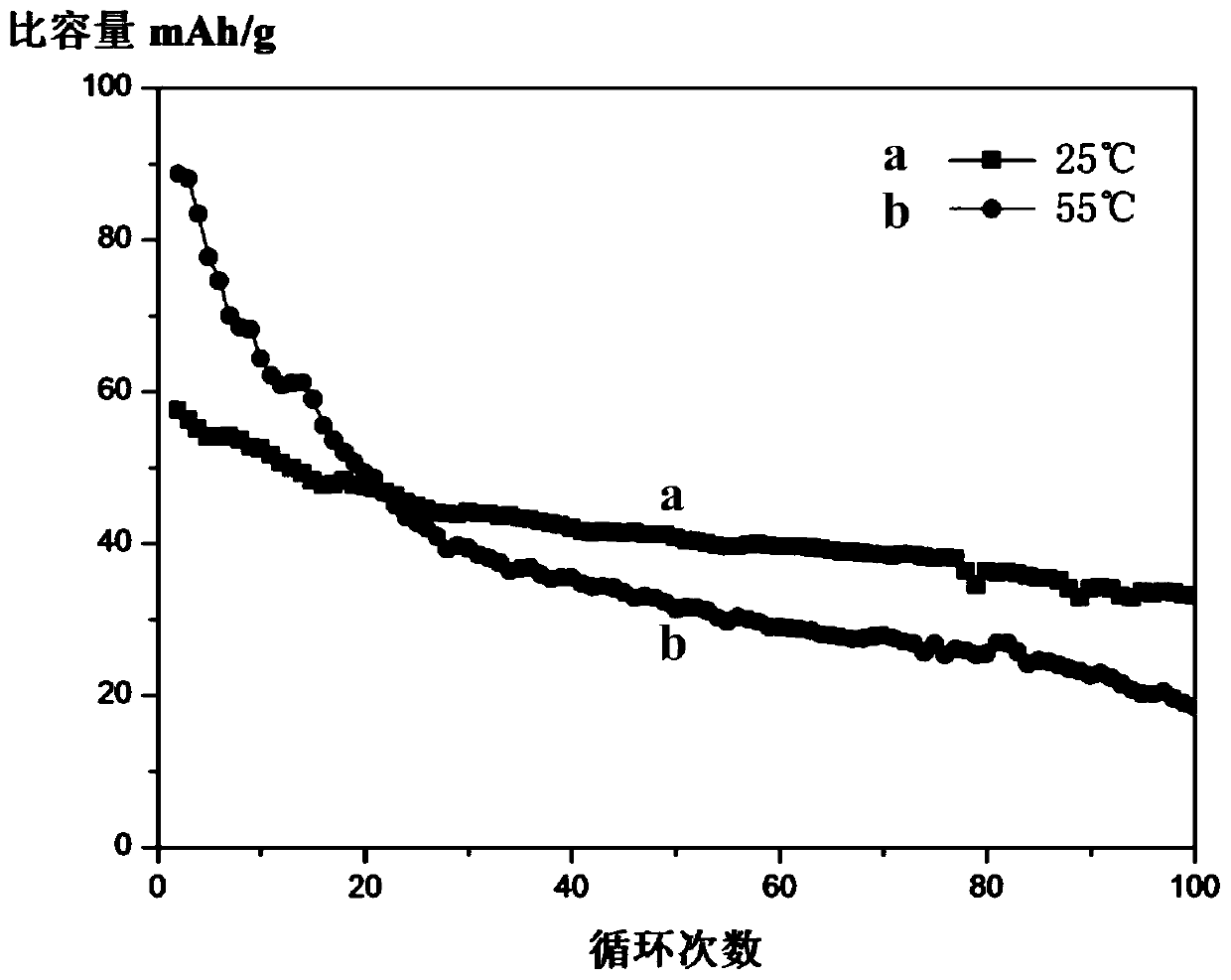

[0071] The specific capacity of the battery at a current density of 50mA / g at 25°C is 51mAh / g.

Embodiment 3

[0073]Others are the same as in Example 1, except that the molar ratio of ZnCl2 to urea is 1:4.

[0074] The specific capacity of the battery at a current density of 50mA / g at 25°C is 46.3mAh / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| freezing point | aaaaa | aaaaa |

| freezing point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap