Power module mounting part and module power supply

A technology of power modules and mounting parts, which is applied in the direction of electrical components, circuits, coupling devices, etc., can solve the problems that power modules cannot meet the size margin and vibration margin of the power module and circuit board installation structure, and achieve easy plugging and unplugging, The effect of reducing production cost and reducing production difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

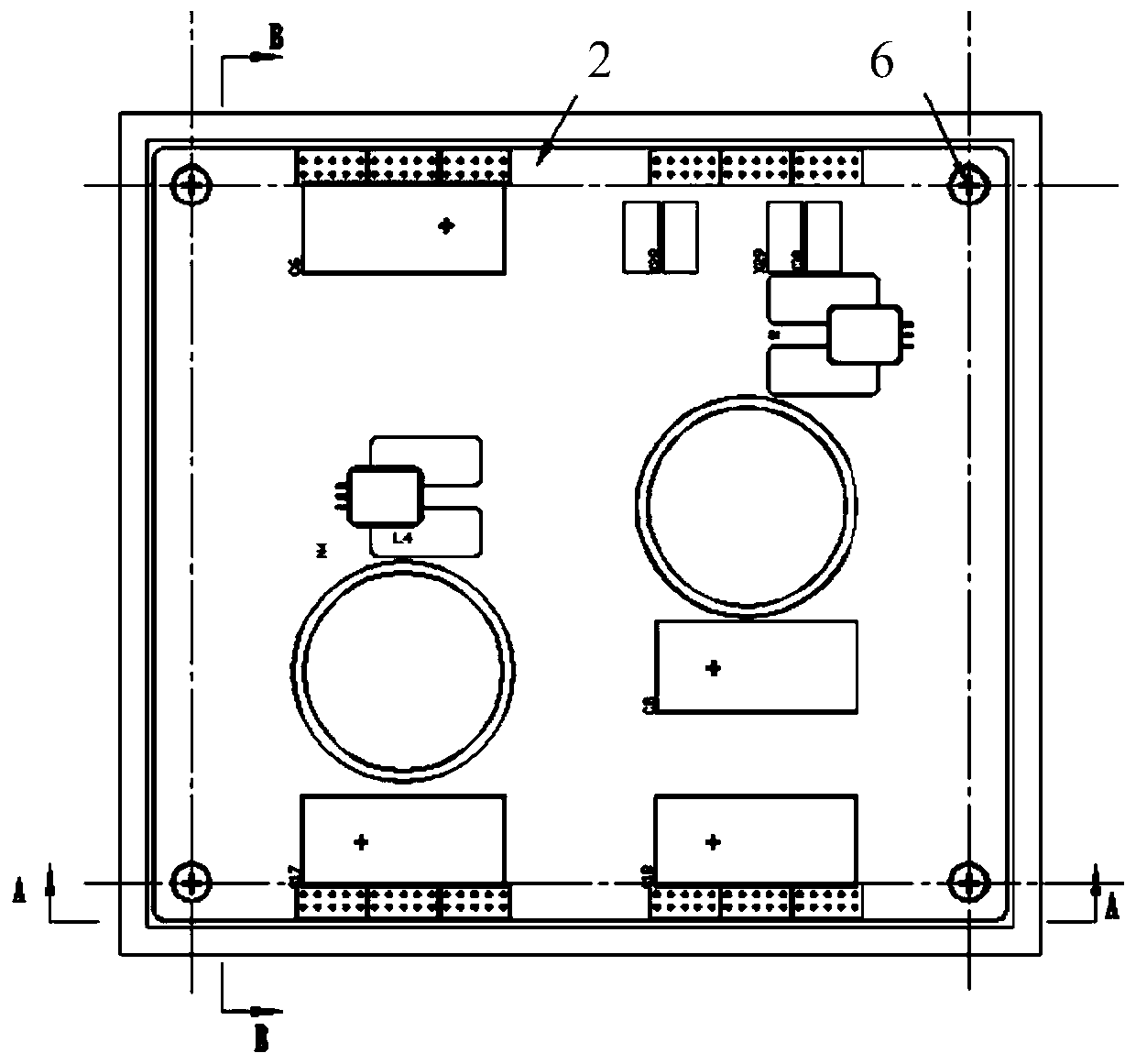

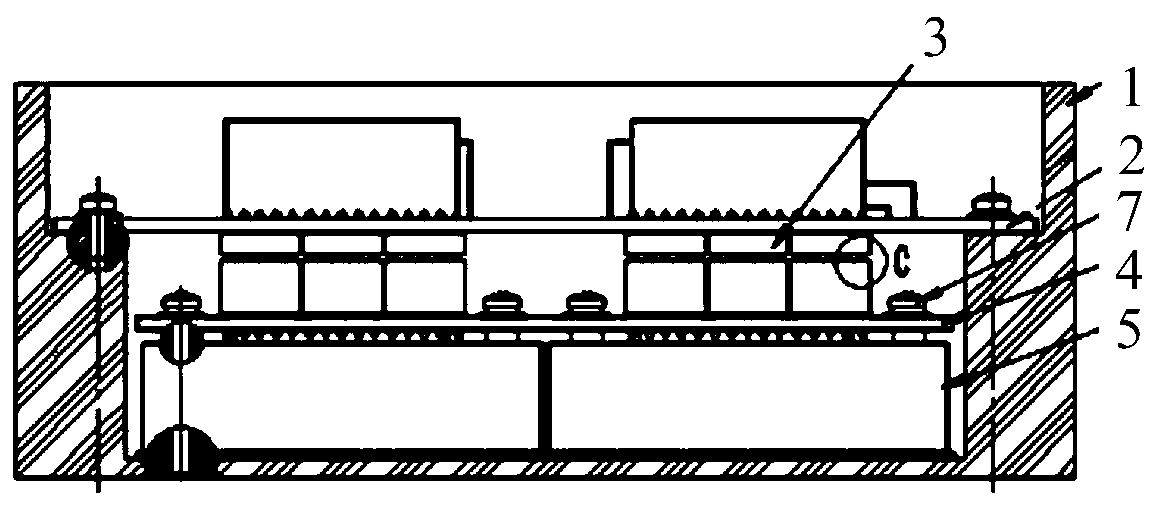

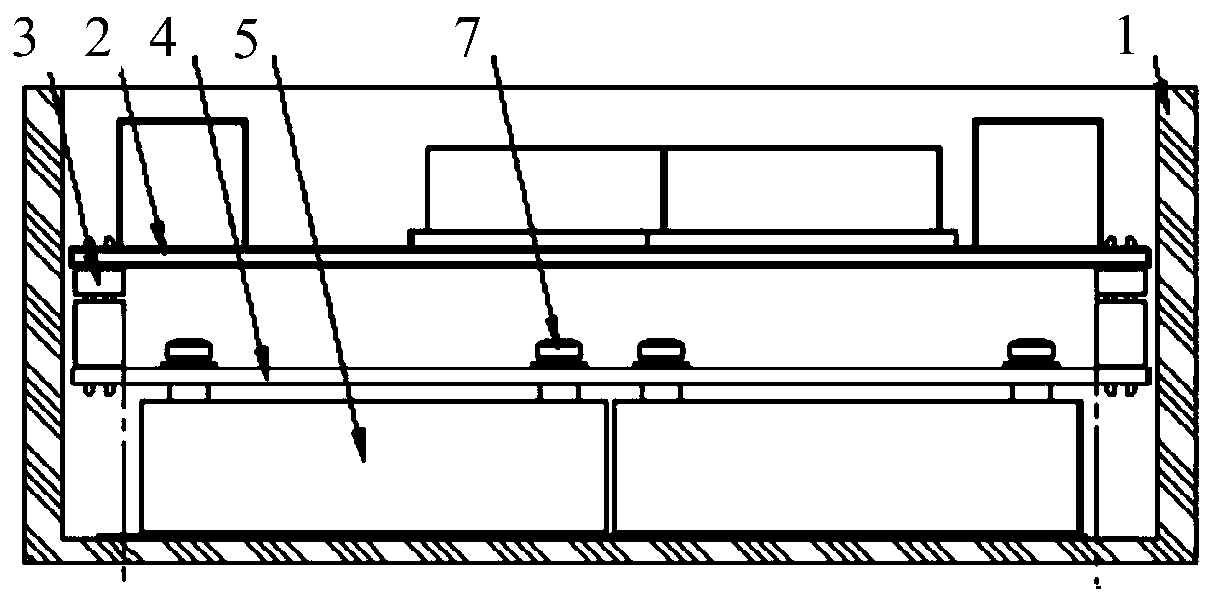

[0043] This embodiment provides a power module mounting part, which is suitable for assembling multilayer circuit boards, see Figure 1 to Figure 5 , Including a casing 1 and a first circuit board 2, a mating connector 3, a second circuit board 4 and a power module 5 which are stacked and connected in sequence. The first circuit board 2 is fixedly connected to the casing 1, and the power module 5 is placed On the bottom plate of the housing 1, the plug-in connector 3, the second circuit board 4 and the power module 5 are located in the space formed by the first circuit board 2 and the housing 1.

[0044] In implementation, the power module 5 is connected to the first circuit board 2 through the second circuit board 4 and the plug-in connector 3 in turn, and the power and signals of the power module 5 are transmitted to the outside through the first circuit board 2.

[0045] Compared with the prior art, the power module mounting part provided in this embodiment realizes the connecti...

Embodiment 2

[0066] This embodiment provides a module power supply, including the power supply module mounting part provided in the first embodiment.

[0067] Compared with the prior art, the beneficial effects of the module power supply provided in this embodiment are basically the same as the beneficial effects of the power supply module mounting member provided in the first embodiment, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com