A flying shooting method, system, and chip bonding method and system

A chip bonding and chip technology, which is applied to the parts of TV system, TV, color TV, etc., can solve the vibration between the bonding head and the camera, the limited range of the camera to take pictures, and affect the efficiency of chip bonding, etc. problem, achieve the effect of shortening the shutter time, shortening the lighting time, and improving the bonding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

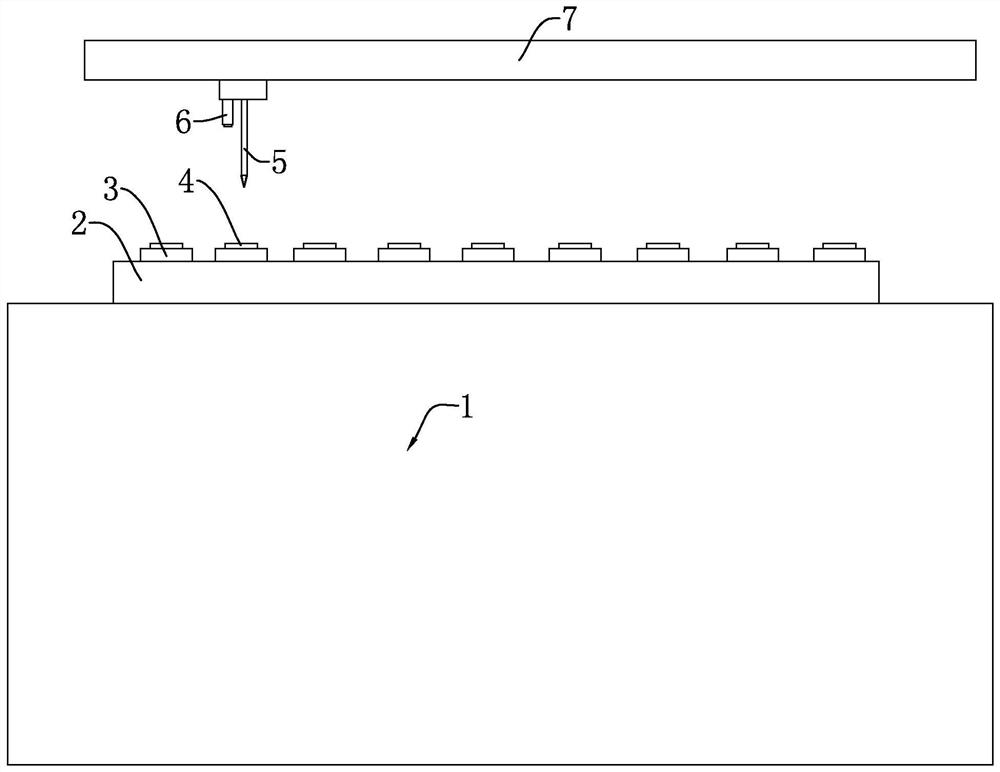

[0038] Embodiment, a kind of LED bonding equipment, refer to figure 1 , including a frame 1, a fixture workbench 2 is fixedly connected to the frame 1, a plurality of fixtures 3 are fixedly connected to the fixture workbench 2, a bonding workbench 7 is arranged above the fixture workbench 2, and the bonding workbench 7 is close to the fixture A bonding head 5 is fixedly connected to one side of the workbench.

[0039] The chip 4 is fixed on the jig 3 , and the chip 4 is welded and bonded through the bonding head 5 .

[0040] The camera 6 with the lens facing the fixture 3 is fixedly connected to the bonding head 5, and the camera 6 is electrically connected to a computer. Path planning is carried out, and the computer controls the bonding head 5 to move according to the specified path, and solders the electronic devices on the chip 4 .

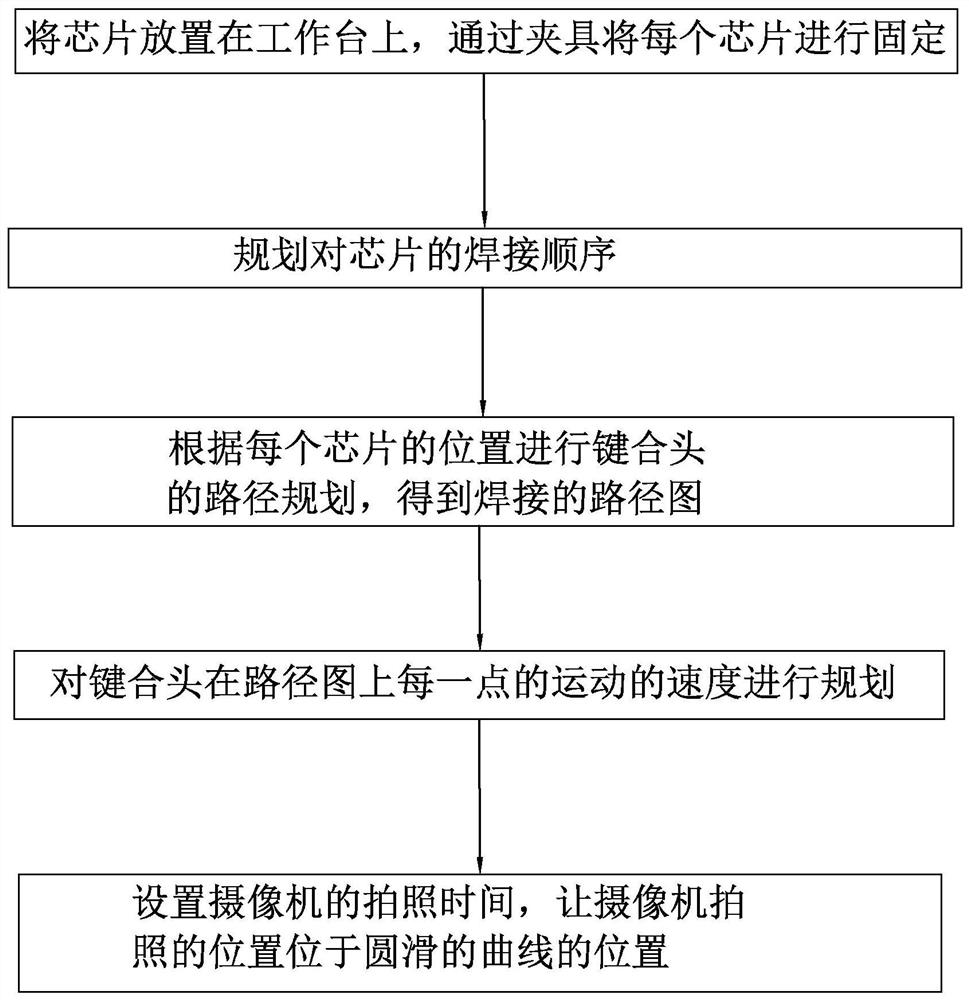

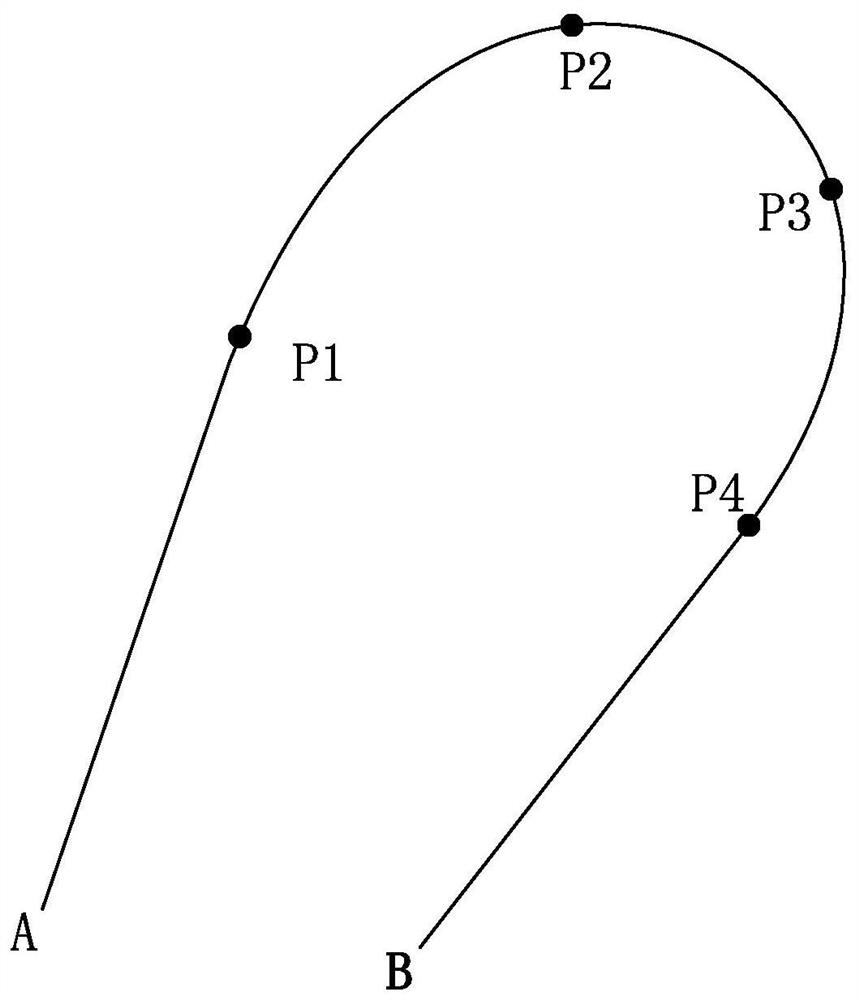

[0041] A kind of bonding method of chip 4, combines figure 2 , image 3 .

[0042] first step,

[0043] Place the chip 4 on the fixtur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com