Camshaft for a pump, in particular a high pressure fuel pump, and pump having a camshaft

一种凸轮轴、凸轮的技术,应用在轴和轴承、燃料喷射泵、凸轮等方向,能够解决凸轮滚子挺杆和滚子磨损等问题,达到磨损小的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

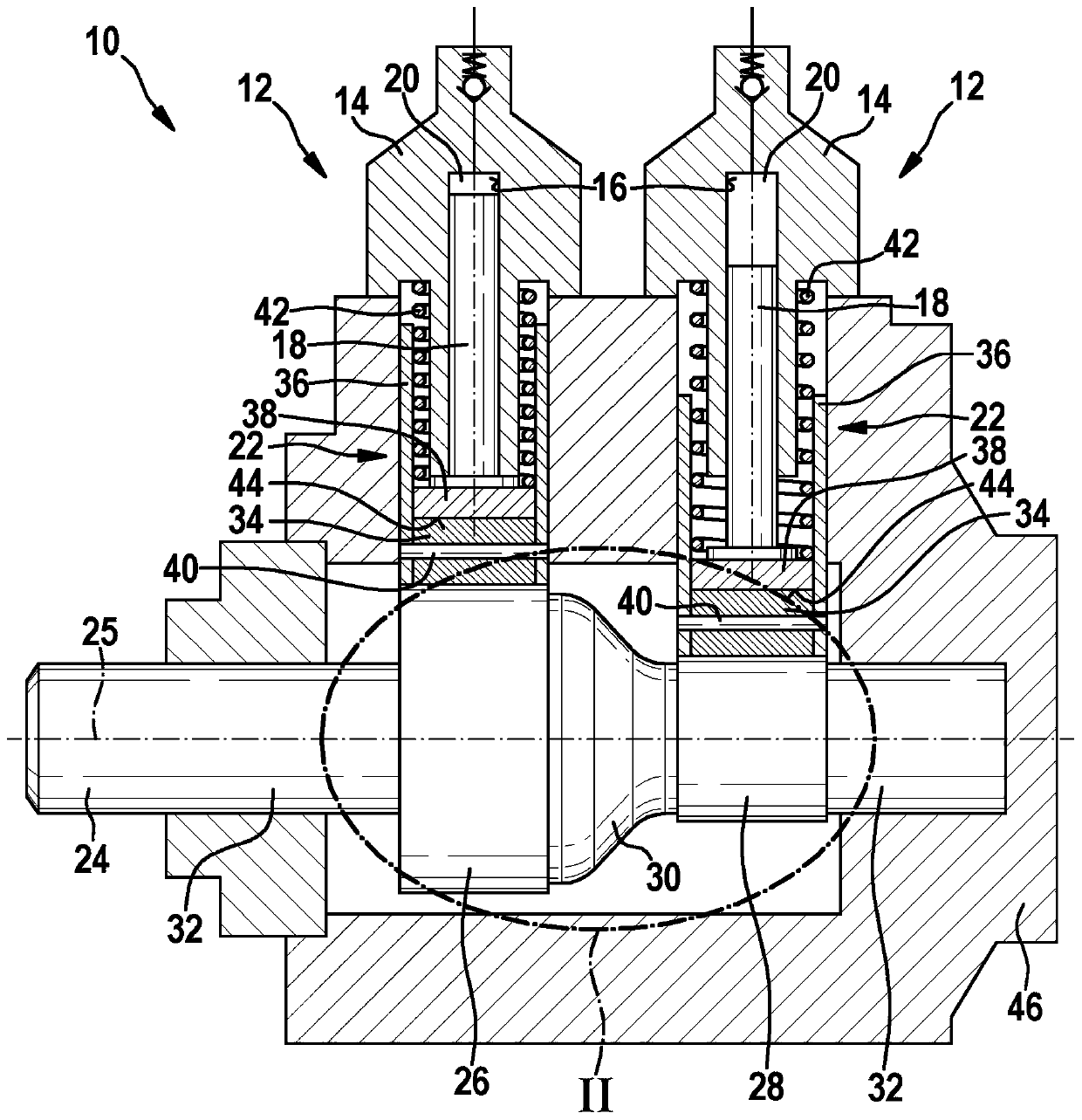

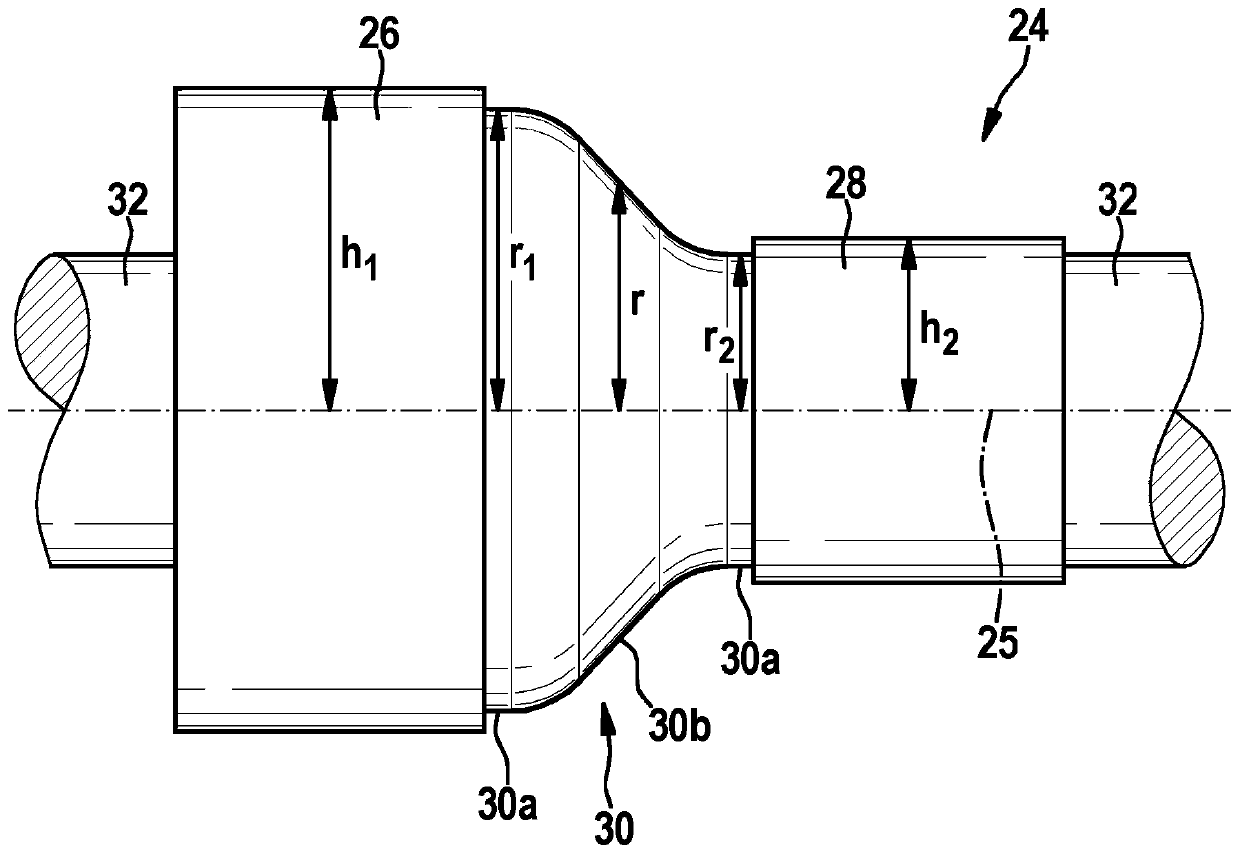

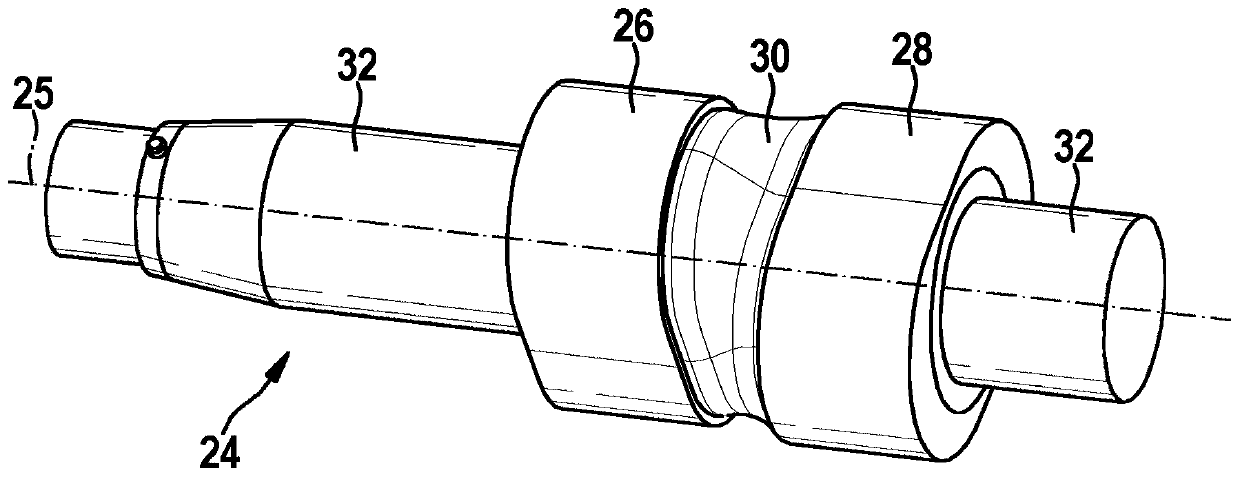

[0006] exist Figure 1 to Figure 6 In a simplified illustration, a pump 10 is shown, which is provided in particular for the high-pressure delivery of fuel in a fuel injection system of an internal combustion engine. The pump 10 has at least two pump elements 12 which each have a housing part 14 in which pump pistons 18 are each movably guided in a cylinder bore 16 which A pump working chamber 20 is delimited in the corresponding cylinder bore 16 . The pump pistons 18 are each driven via a tappet 22 by the camshaft 24 in a lifting motion in at least approximately radial direction relative to the rotational axis 25 of the camshaft 24 . The axis of rotation 25 of the camshaft 24 is coaxial with its longitudinal axis. The camshaft 24 can be part of the pump 10 , or alternatively it can also be provided that the pump 10 does not have its own camshaft and that the camshaft 24 is part of the internal combustion engine.

[0007] The camshaft 24 has two cams 26 , 28 arranged one be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com