Medical pipe and preparation method thereof

A technology for pipes and polytetrafluoroethylene, applied in the field of medical devices, can solve problems such as large costs and losses, and achieve the effects of reducing the use accident rate, preventing delamination abnormalities, and improving twist control performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] In this embodiment, the preparation method of medical tubing includes the following steps:

[0022] Step S1: firstly etch the PTFE inner layer, fix the etched PTFE inner layer on the mandrel, and immerse the mandrel in the dipping tank with adhesive to make the adhesive The binding agent is coated on the outer surface of the polytetrafluoroethylene inner layer. Wherein, the binder in the dipping tank may be at least one of polyamide, polyimide, polyether block amide (PEBA), and thermoplastic polyurethane (TPU). The solid content of the binder may be 10-20%. The solid content in the present invention refers to the mass percentage of the remaining part of the binder after drying. The role of the adhesive is to better bond the layers of the composite pipe together.

[0023] Step S2: Put the mandrel vertically into an oven, heat and cure the adhesive on the outer surface of the inner layer of polytetrafluoroethylene, and set the curing temperature according to the characterist...

Embodiment 1

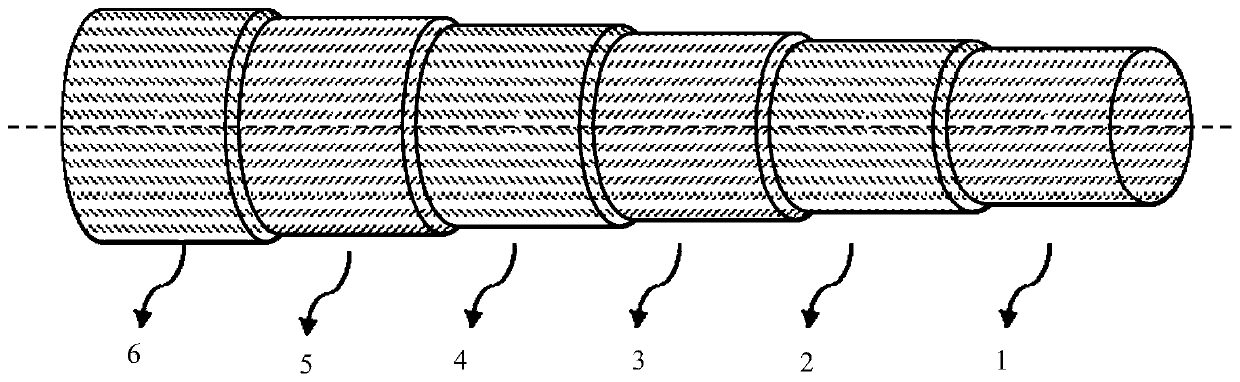

[0029] The core rod 1 is a stainless steel rod with a polytetrafluoroethylene coating. The etched polytetrafluoroethylene inner layer is sheathed on the core rod 1, and the core rod 1 is immersed in a dipping tank with an adhesive, so that the adhesive is coated on the outer PTFE inner layer On the surface. Among them, the binder in the dipping tank is polyether block amide (PEBA) with a solid content of 20%. Put the mandrel 1 into an oven vertically to heat and cure the adhesive on the outer surface of the inner layer of polytetrafluoroethylene. The temperature of heat curing is in the range of 100-240°C. A bonding layer is formed on the outer surface of the inner layer. A braiding machine is used to braid braided wires on the bonding layer to form a braided layer; an outer layer is sheathed on the outer part of the braided layer, and a welding machine is used for thermal welding and bonding. The outer layer is made of polyether block amide (PEBA). A sleeve is sleeved on t...

Embodiment 2

[0031] The core rod 1 is a stainless steel rod with a polytetrafluoroethylene coating. The etched PTFE inner layer is sheathed on the core rod 1, and the core rod 1 is immersed in a dip tank with an adhesive, so that the adhesive is coated on the outer PTFE inner layer. On the surface. Among them, the binder in the dipping tank is nylon 6 (PA6) with a solid content of 20%. Put the mandrel 1 into an oven vertically to heat and cure the adhesive on the outer surface of the inner layer of polytetrafluoroethylene. The temperature of heating and curing ranges from 100 to 260°C. A bonding layer is formed on the outer surface of the inner layer. A braiding machine is used to braid braided wires on the bonding layer to form a braided layer; an outer layer is sheathed on the outer part of the braided layer, and a welding machine is used for thermal welding and bonding. The outer layer is made of polyether block amide (Pebax). A sleeve is sleeved on the outer layer and thermally weld...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com