A plate stacking system and stacking method for ultra-thin plates

An ultra-thin plate and stacking technology, which is applied to the plate stacking system and the field of stacking, can solve the problems of low stacking efficiency of ultra-thin plates, and achieve the effect of ensuring stacking quality, high efficiency and edge quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

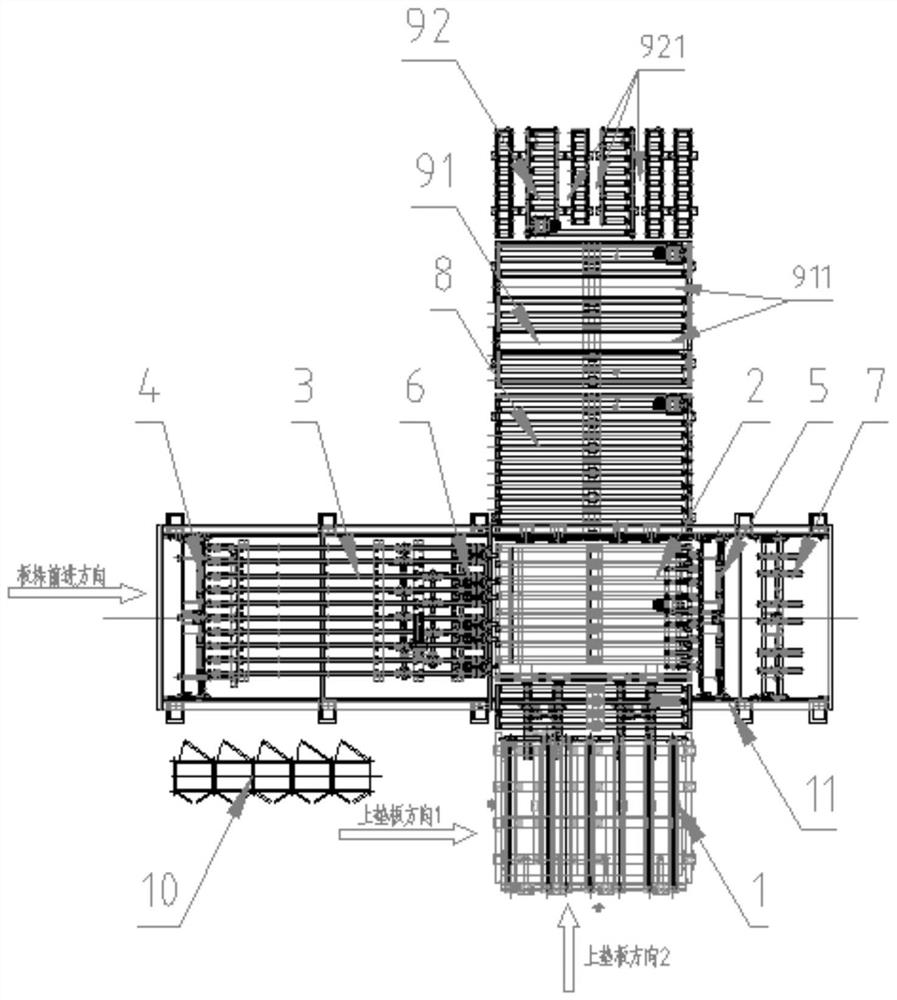

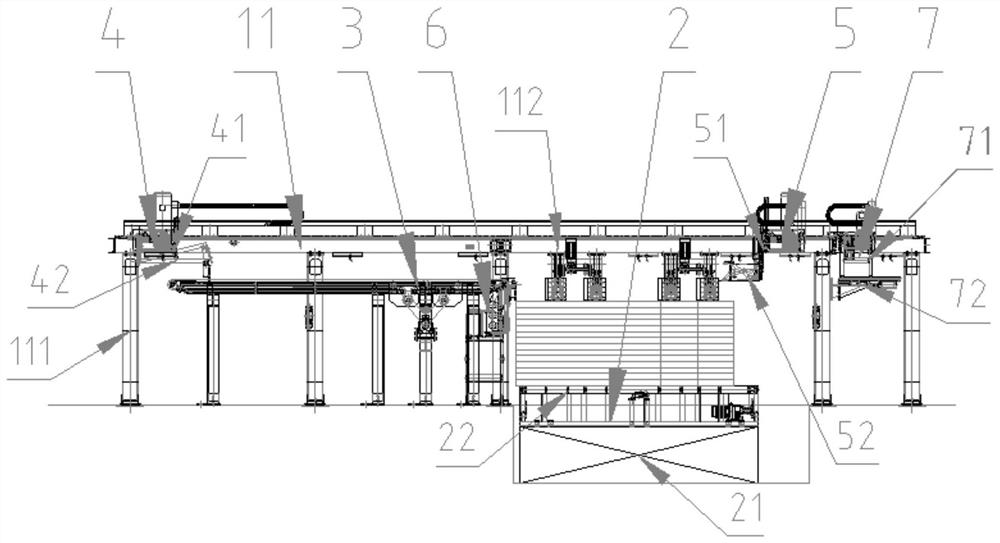

[0058] combine figure 1 and figure 2 As shown, according to an embodiment of the present invention, the pushing plate device 4 includes: a first driving unit 41 , and a first pushing plate 42 disposed on the first driving unit 41 . In this embodiment, the first push plate 42 is vertically fixedly connected with the first driving unit 41 , and its lower end is flush with the conveying plane of the conveyor 3 . Through the above arrangement, when the ultra-thin plate is transported on the conveyor 3, the pushing effect on the ultra-thin plate can be realized by the abutment of the first push plate 42 against the side of the ultra-thin plate, thereby preventing the ultra-thin plate from being placed on the conveyor 3 The skid on the surface is favorable, and the stable conveying of ultra-thin plates is realized. It should be noted that when the conveyor 3 receives the upstream ultra-thin plate, the push plate device 4 is in the avoidance position, which ensures the smooth feed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com