Local repair method of loam wall

A technology of partial repair and rammed earth wall, which is applied in building maintenance, construction, building construction, etc. It can solve the problems of difficult local repair, soil cracking, and failure to form, so as to achieve rapid repair, improve water resistance and durability the overall effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A local repair method for rammed earth walls, including the following steps:

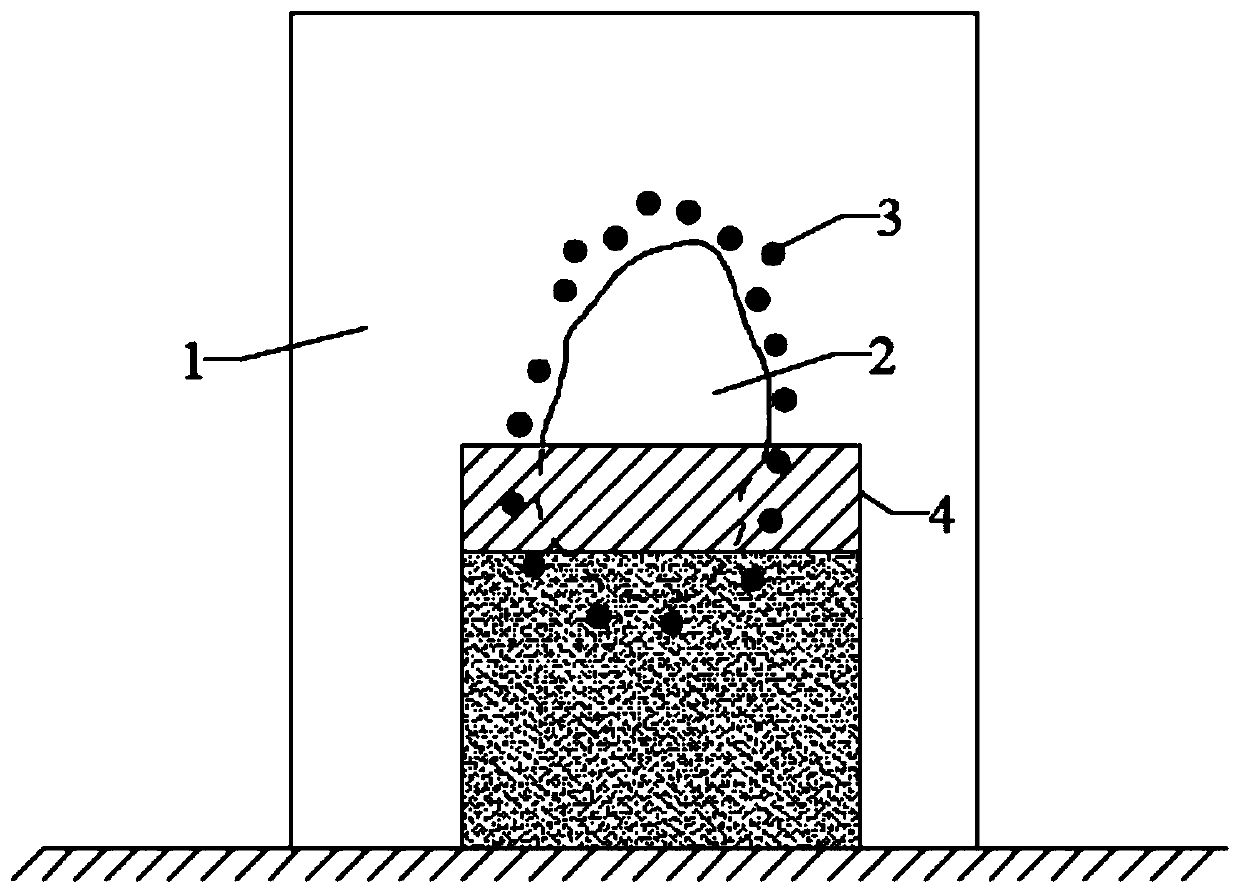

[0034] Step 1: Clean up the weathered peeling layer of the local damaged part 2 on the surface of the rammed earth wall 1, make holes on the repaired surface of the local damaged part 2, and insert the shear key 3 in turn, then clean and blow away the floating dust left on the wall;

[0035] Step 2: Apply the gelling interface agent evenly on the repaired surface of the partially damaged part 2;

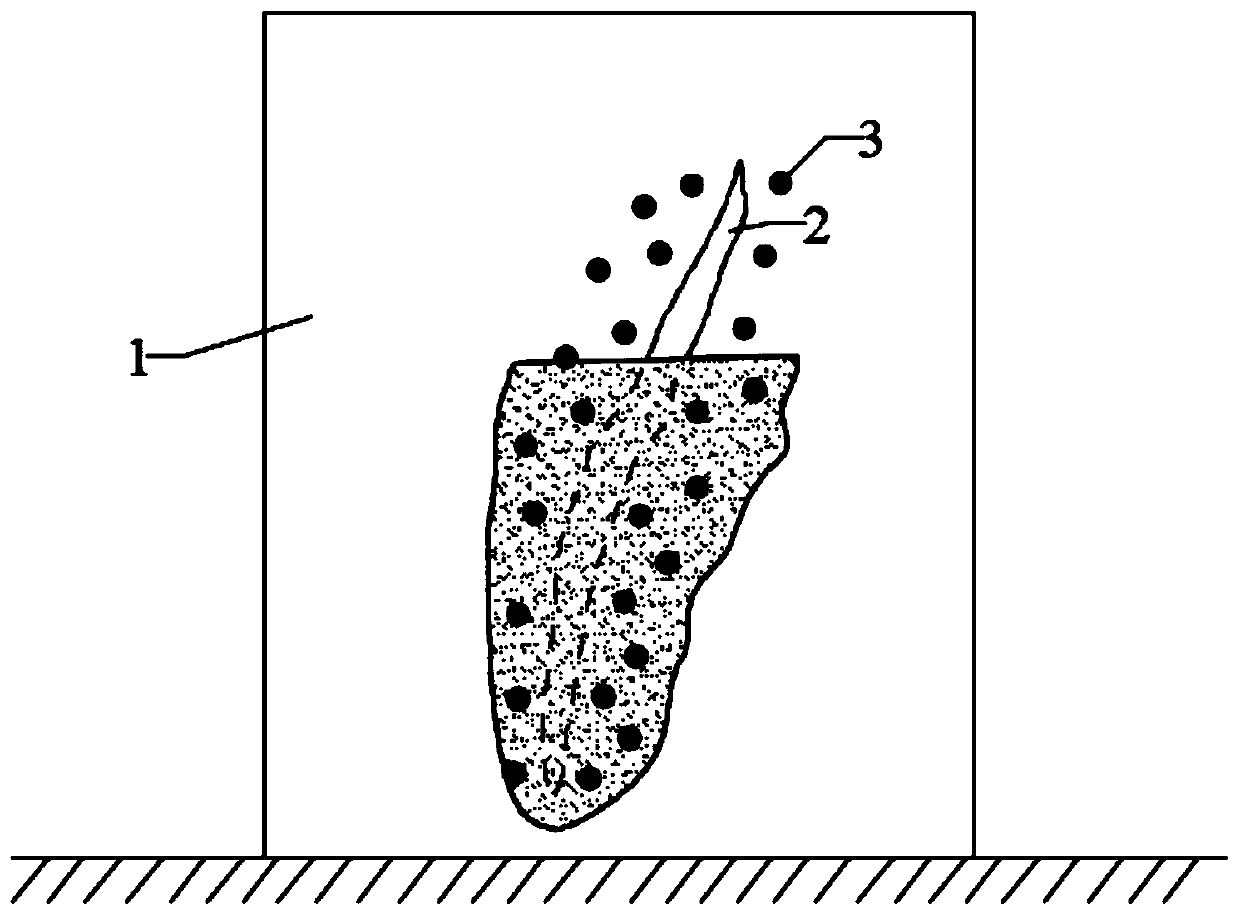

[0036] Step 3: Support a template 4 at the bottom end of the partially damaged part 2. The template 4 and the repaired surface enclose a repair space. The raw soil is taken from bottom to top to fill the repair space several times, and the repair space is filled for each time. After ramming the constructed raw soil for the next filling, repeat the above operation until the raw soil fills up the local damaged part 2, and remove the template 4. Finally, the side form is not used at the closing of the local d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com