A ferrule-type connection flared plastic pipe fitting

A technology of plastic pipe fittings and ferrule type, which is applied in the direction of pipes/pipe joints/pipe fittings, pipes, rigid pipes, etc. It can solve the problems of inability to resist impact force, inability to sound insulation, and the connection between the first nut and the pipe body is not firm, etc., to achieve Prevent random movement, avoid damage to pipe fittings, and have the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

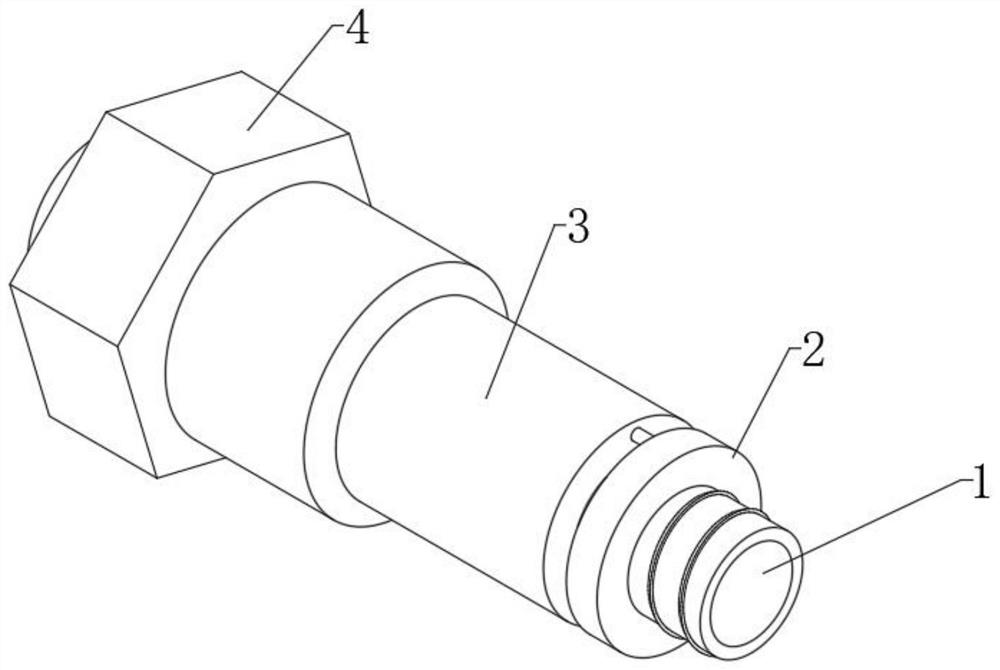

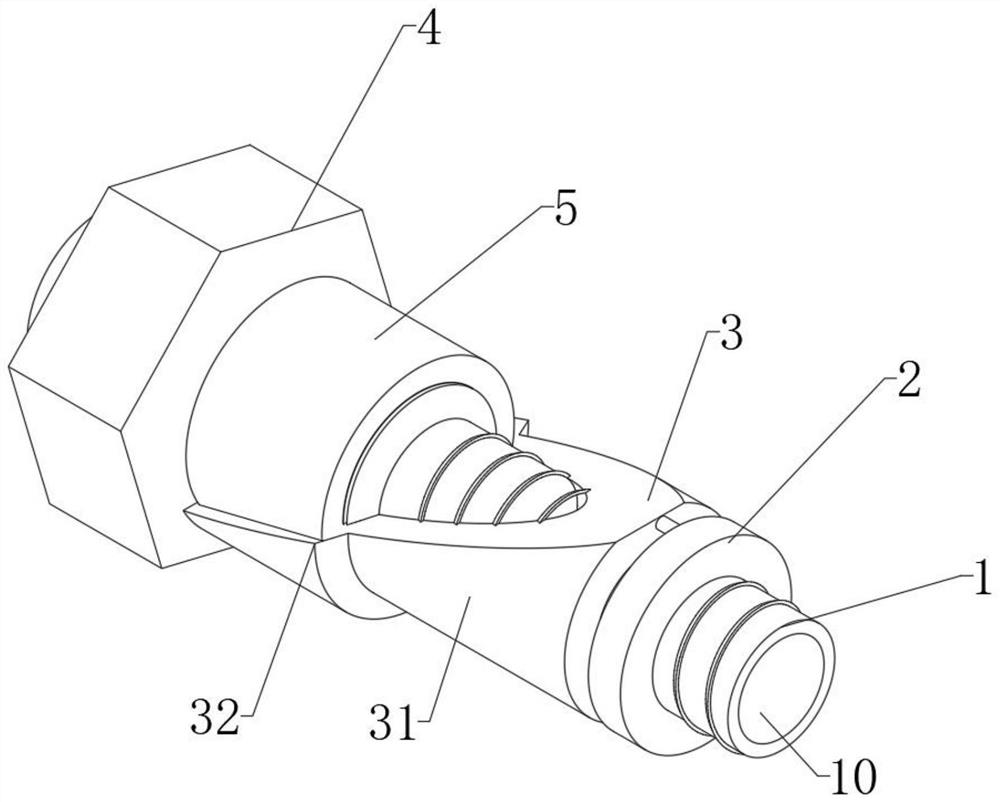

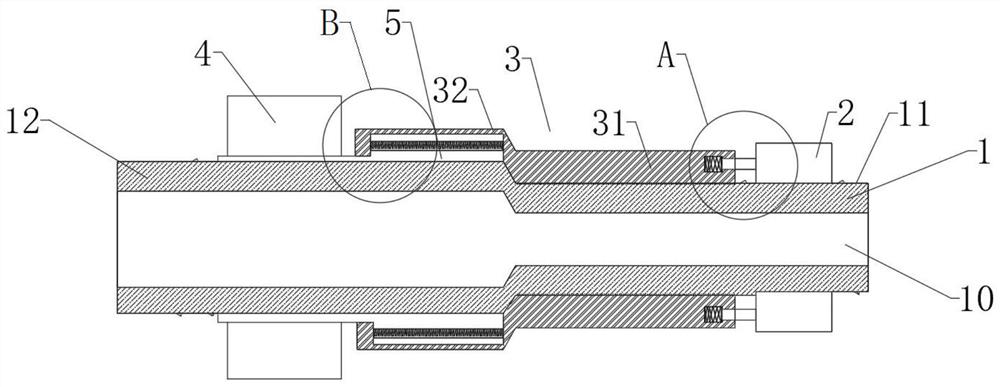

[0028] A ferrule-type connection flaring plastic pipe fitting, in order to solve the problem that the ordinary flaring pipe body cannot resist impact force and the first nut is not firmly connected with the pipe body, as a preferred embodiment, as figure 1 , figure 2 , image 3 , Figure 4 with Figure 5 As shown, it includes a pipe fitting 1, the inner cavity of the pipe fitting 1 is provided with a connected pipe hole 10, the pipe fitting 1 includes a narrow mouth joint 11 and a flared joint 12, the pipe fitting 1 is threaded with a first nut 3 near the outer wall of the middle part, and the first nut 3 includes The joint sleeve 31 and the flared sleeve 32, the inner wall of the joint sleeve 31 is threadedly connected with the outer wall of the thin mouth joint 11, the flared sleeve 32 is threaded with the outer wall of the flared joint 12, the outer wall of the thin mouth joint 11 is threadedly connected with a fixed block 2, and the fixed block 2 A limit rod 6 is arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com