Industrial control equipment based on industrial Internet platform and working method of industrial control equipment

A technology of industrial Internet and industrial control, applied in the direction of program control, computer control, general control system, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

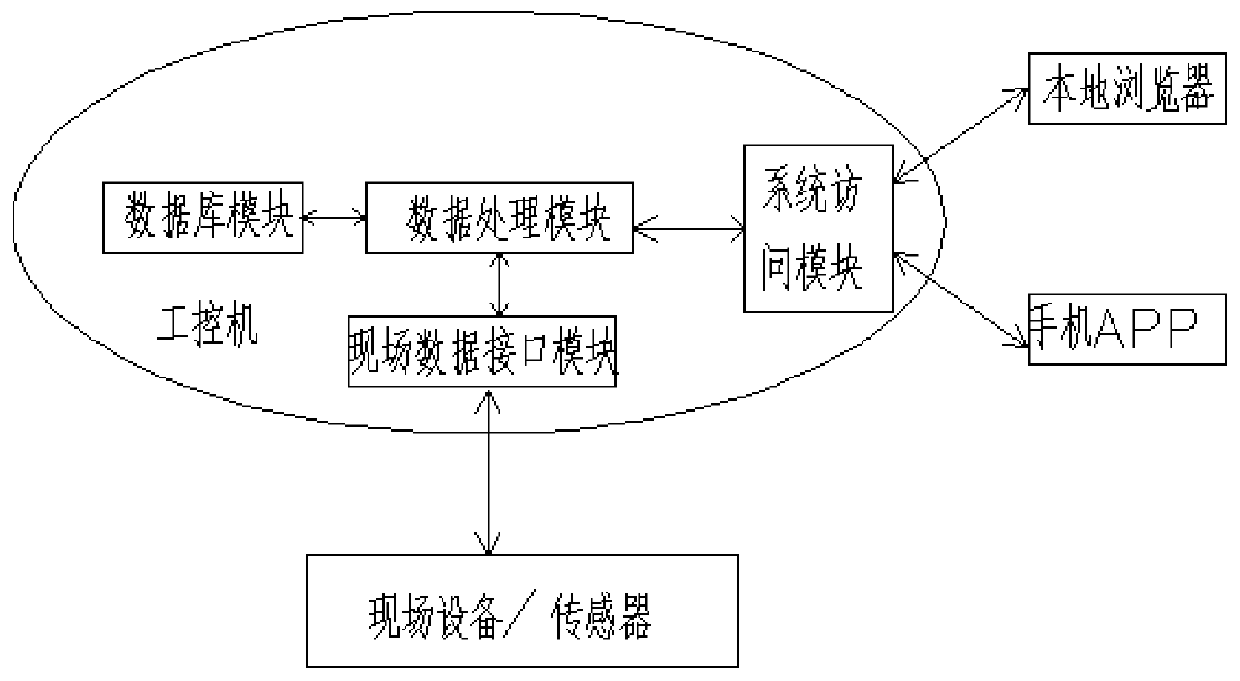

[0038] An industrial control device based on an industrial Internet platform, including one or more industrial computers; such as figure 1 As shown, the industrial computer at least includes a field data interface module, a system access module, a database module, and a data processing module. The industrial control equipment of the present invention can choose one industrial computer to cover the whole site, or install multiple industrial computers, each of which only covers a part of the site, and multiple industrial computers can form different topological network structures.

[0039] Wherein, the field data interface module is used to directly connect with field devices or field sensors through various field communication protocols; in the present invention, the field data interface module can realize all the functions of the industrial gateway, and all the devices that can be connected with the industrial gateway can Connected to the industrial computer, the field data in...

Embodiment 2

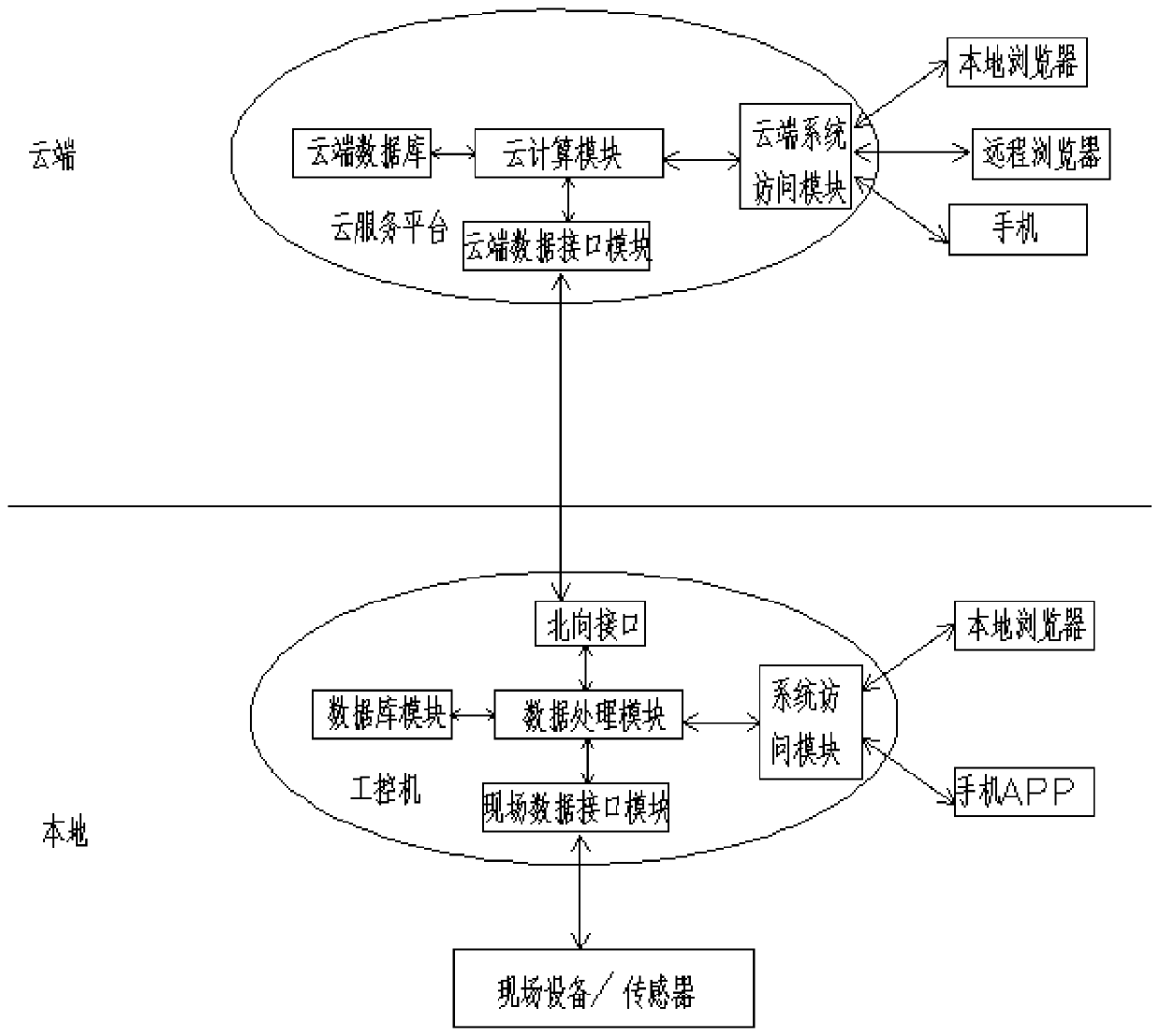

[0050] Embodiment 2 is different from Embodiment 1 in that the industrial control equipment also includes a northbound interface; figure 2 As shown, the northbound interface is used as the connection port between the industrial computer and the cloud management platform, and it has the interface function of providing or receiving information upwards. The data provided by the northbound interface includes the data and data that the northbound interface can obtain from the field data interface. The new data generated by the processing module and its own data; the data sent from the cloud that can be accepted by the northbound interface.

[0051] Wherein, the cloud management platform includes a cloud data interface module, a cloud computing module, a cloud database and a cloud system access module; wherein,

[0052] The cloud data interface module is connected to the northbound interface for data interaction with the industrial computer;

[0053] The cloud computing module is ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap