Safety rope mechanism for installing main transformer

A main transformer and safety rope technology, applied in the field of substation appliances, can solve the problems of narrow space and danger on the top surface of the main transformer, and achieve the effect of improving operation safety and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further explained below in conjunction with the accompanying drawings.

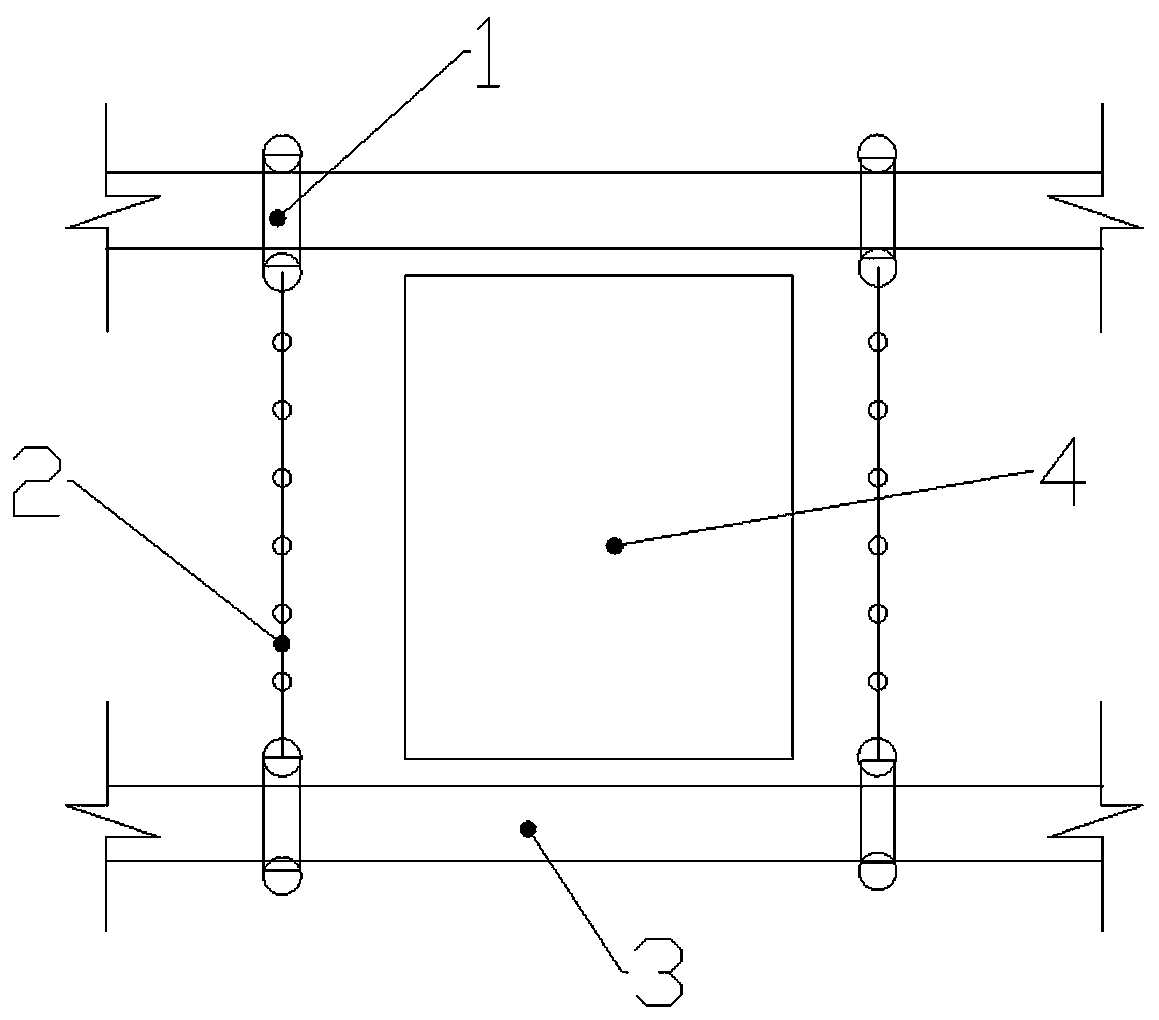

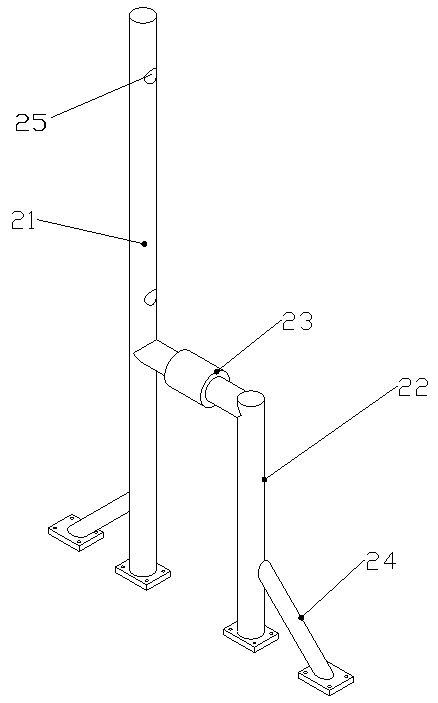

[0014] This embodiment is a safety rope mechanism for installing a main transformer, which includes at least four "h"-shaped brackets 1 and several safety ropes 2 connected to the brackets. The bracket 1 includes a long rod 21, a short rod 22 and a threaded sleeve 23,

[0015] The upper end of the short rod 22 is provided with a horizontal connecting rod, and the long rod 21 is also provided with a horizontal connecting rod corresponding to the position of the upper connecting rod of the short rod 22, and the two ends of the threaded sleeve 23 are respectively connected to two connecting rods. To adjust the distance between the long rod 21 and the short rod 22;

[0016] Two bolt holes 25 for passing the safety rope 2 are opened on the long rod 21, and the two bolt holes 25 are arranged vertically with an interval of 600-1000 mm. The support is h-shaped, and the lower...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap