A cleaning device for inner holes of pipe fittings

A technology for cleaning equipment and inner holes, which is applied in the field of cleaning equipment for inner holes of pipe fittings. It can solve the problems of insufficient cleaning of the inner wall in the horizontal direction, and achieve the effect of convenient operation and sufficient cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

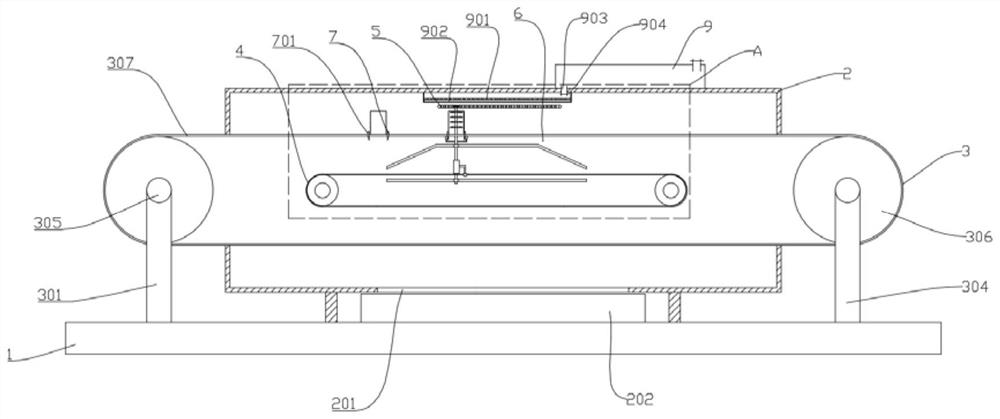

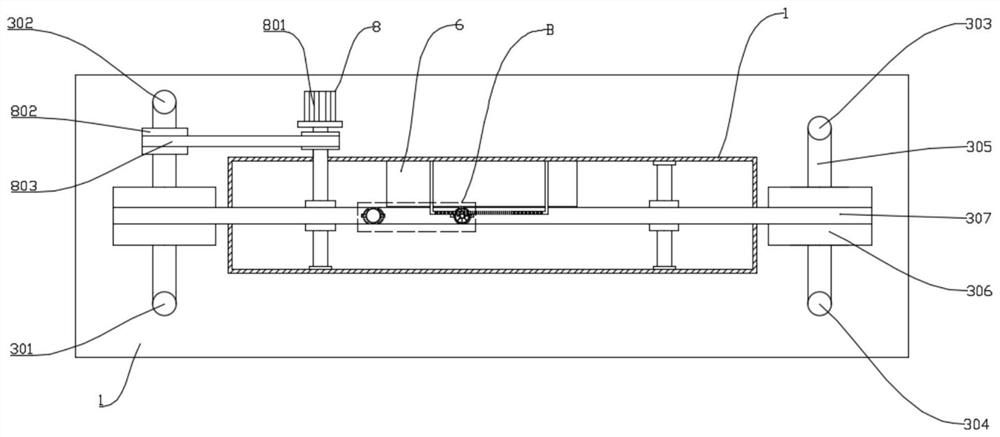

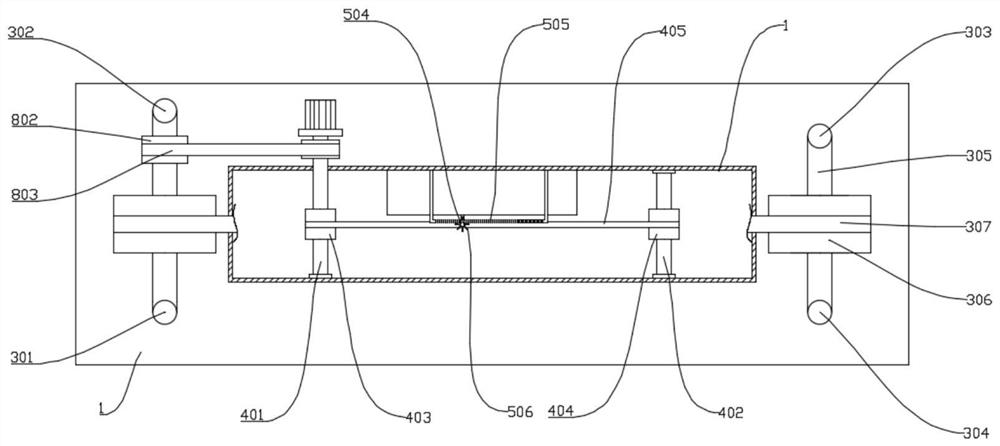

[0035] Such as Figure 1 to Figure 7As shown, the present invention provides a cleaning device for the inner hole of pipe fittings, which includes a bottom plate 1 and a box body 2, and the box body 2 is centrally installed on the bottom plate 1; a transmission group is installed at both ends of the bottom plate 1 3. The No. 2 transmission group 4, the cleaning group 5, the guide group 6 and the clamping group 7 are installed inside the box body 2, and the power group 8 is arranged on the rear side of the box body 2; the No. 1 transmission group 3 runs through the box left and right Body 2, No. 2 transfer group 4 is located inside No. 1 transfer group 3, cleaning group 5 is installed on the upper end of No. 5, the clamping group 7 is installed on the upper end of the No. 1 transmission group 3 and cooperates with the cleaning group 5, and the power group 8 cooperates with the No. 1 transmission group 3 and the No. 2 transmission group 4; the bottom of the box body 2 is provide...

Embodiment 2

[0047] Such as Figure 1 to Figure 7 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference between this embodiment two and embodiment one is: as Figure 7 As shown, the left and right ends of the No. 1 conveyor belt 307 are provided with support columns a10, and the left and right ends of the chain 404 are provided with support columns b11; ;

[0048] Working process: place the part 12 in the arc claw 703, start the motor 801, and make the first transmission group 3 and the second transmission group 4 drive, the part 12 moves on the first conveyor belt 307, while the part 12 moves, The second transmission group 4 drives the cleaning group 5 to move, the brush rod 502 is restricted by the guide group 6 to move upward, and is inserted into the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com