Steam turbine independent control high-pressure main steam regulating valve

An independent control, steam turbine technology, applied in the direction of mechanical equipment, engine components, machines/engines, etc., can solve the problems of complex structure design, spray coating peeling, frequent problems, etc., achieve simple structure design, improve maintenance efficiency, and easy disassembly and maintenance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

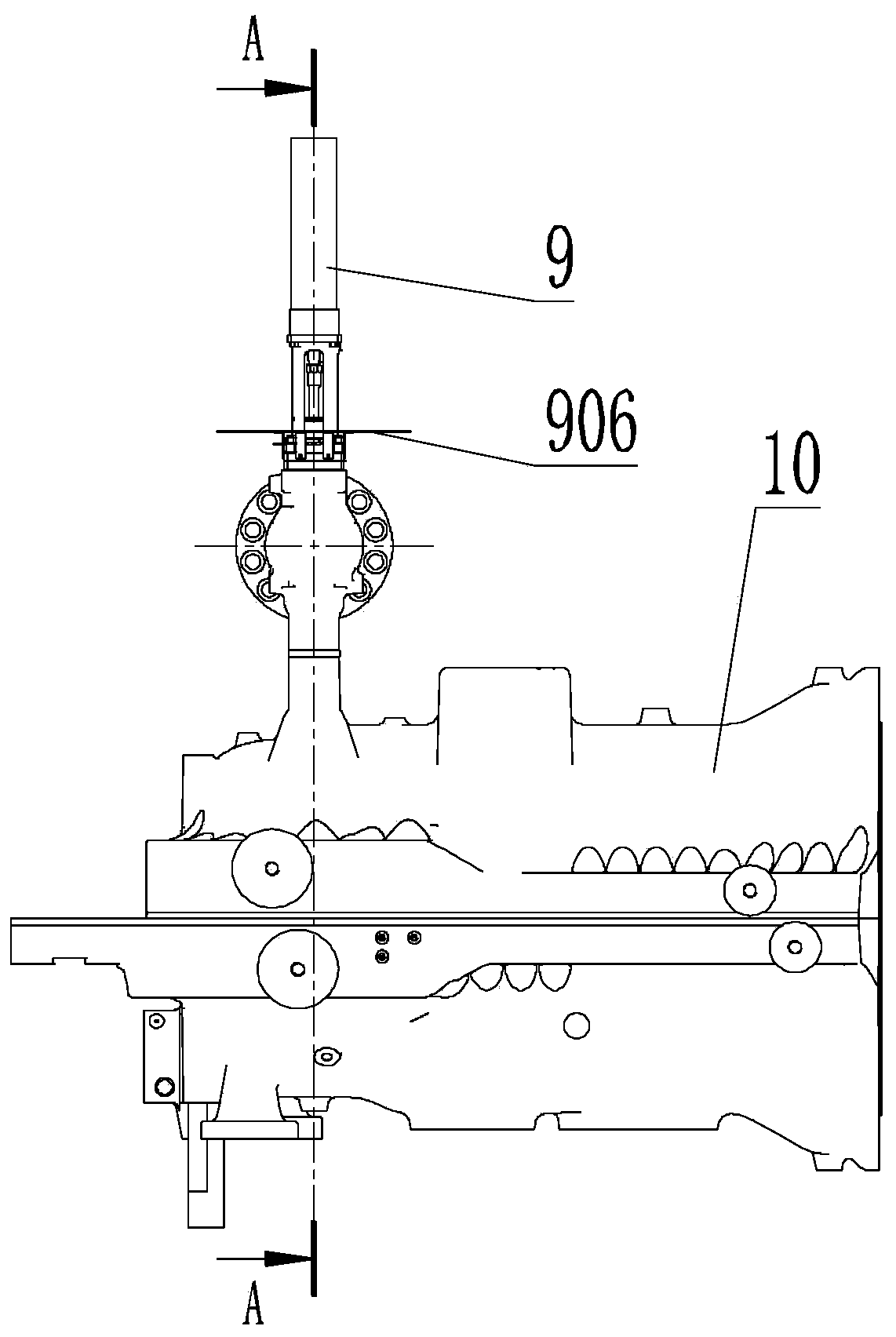

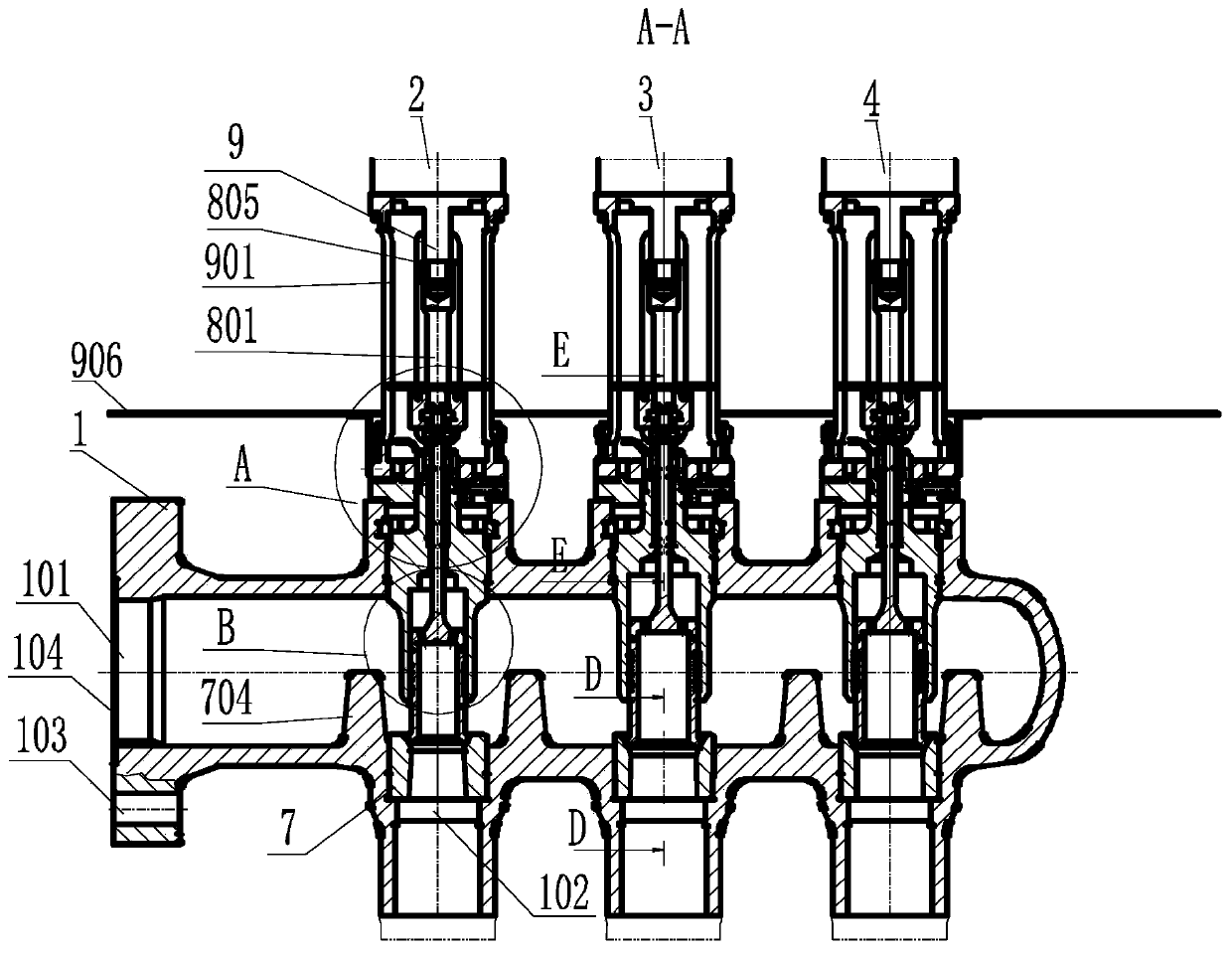

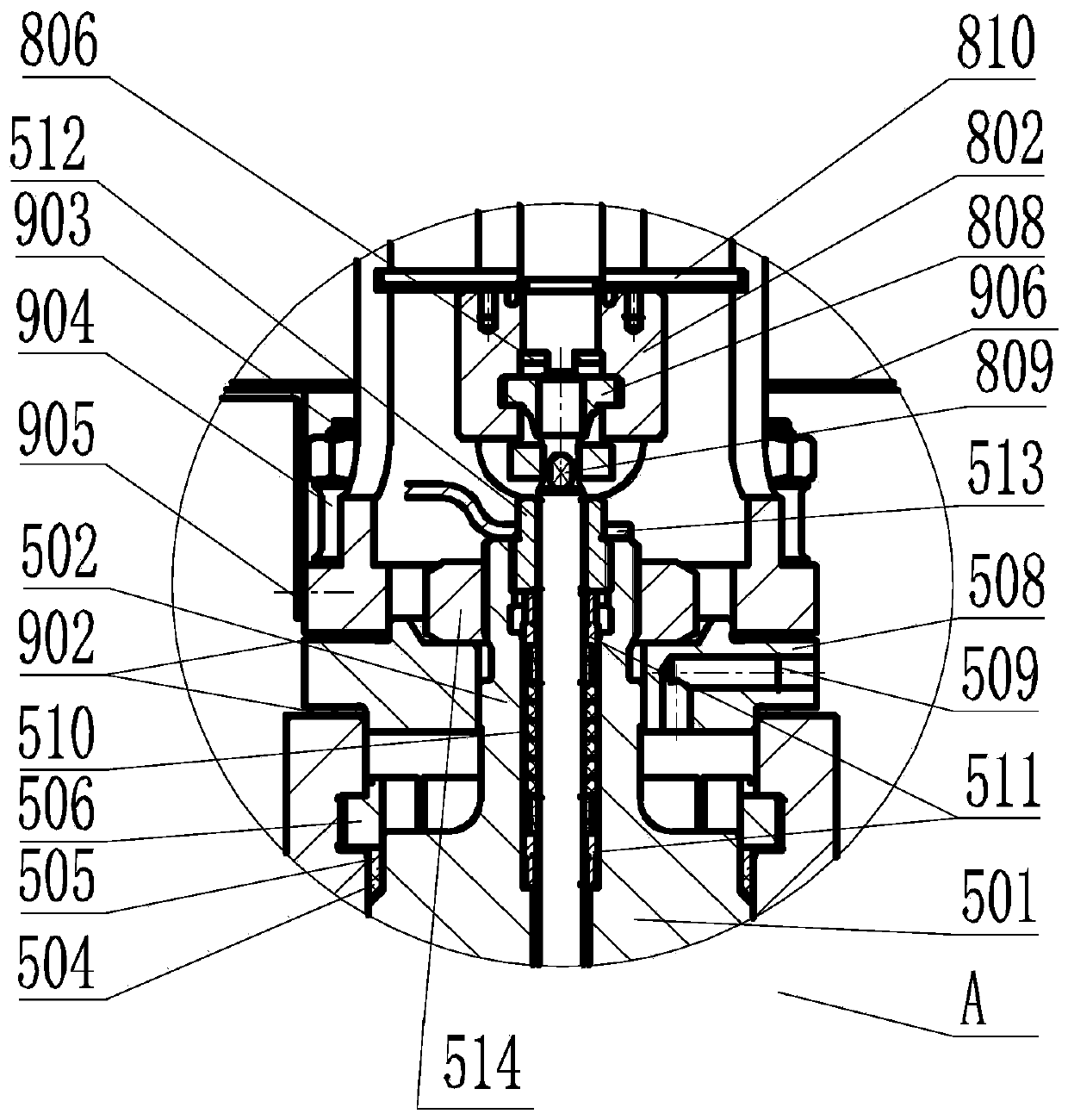

[0043] Such as Figure 1-6 As shown, a steam turbine independently controls the high-pressure main steam regulating valve, including a valve body 1, a cavity is opened inside the valve body 1, a steam inlet 101 is opened on the left end surface of the valve body 1, and the upper side of the valve body 1 is opened at intervals on the same Three guide holes of row, install valve A2, valve B3, valve C4 respectively in three guide holes, the lower side of valve body 1 offers three steam outlet holes 102, and three steam outlet holes 102 are the same as three guide holes axis relative.

[0044] The end face of the steam inlet 101 of the valve body 1 is provided with a flange integrally connected to the valve body 1, and the main steam valve is connected to the main steam valve through the bolts installed in the flange hole. Tooth-shaped sealing gasket realizes the end face sealing of the two valves. The main steam regulating valve adjusts and controls the steam input by the main ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com