Ground test simulation device and method for separating device

A separation device and ground test technology, applied to jet propulsion devices, rocket engine devices, machines/engines, etc., to achieve the effects of reducing economic losses, verifying reliability, and reducing separation risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

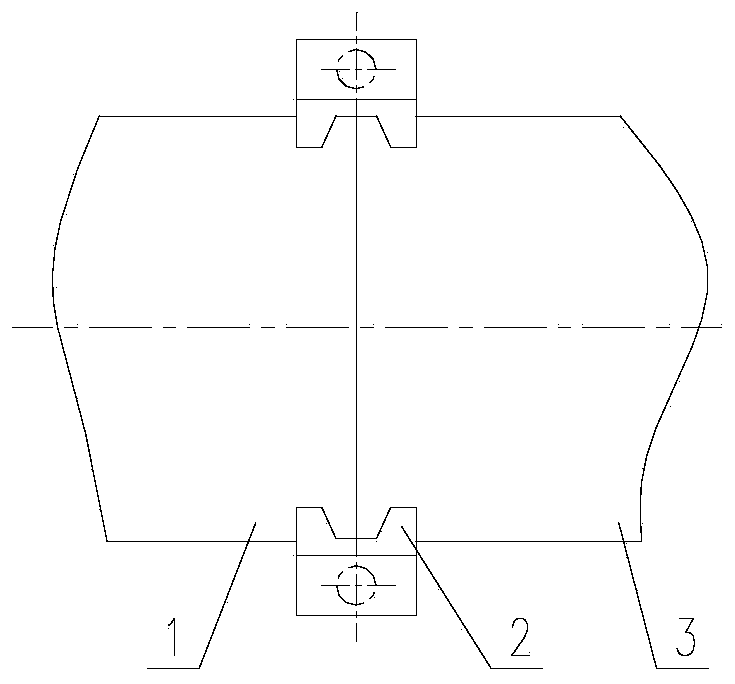

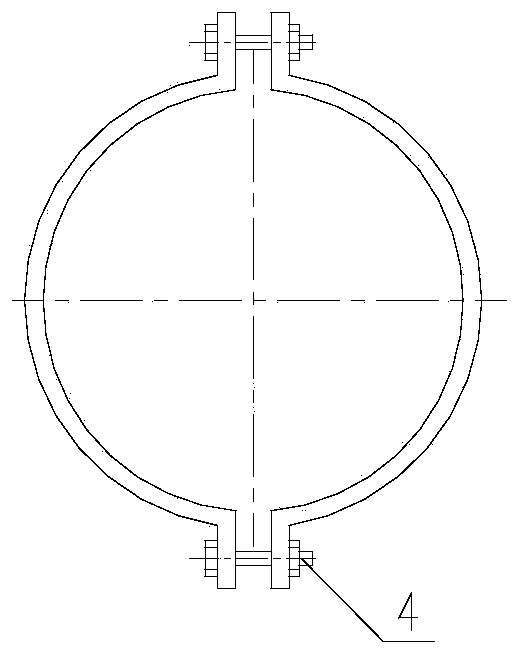

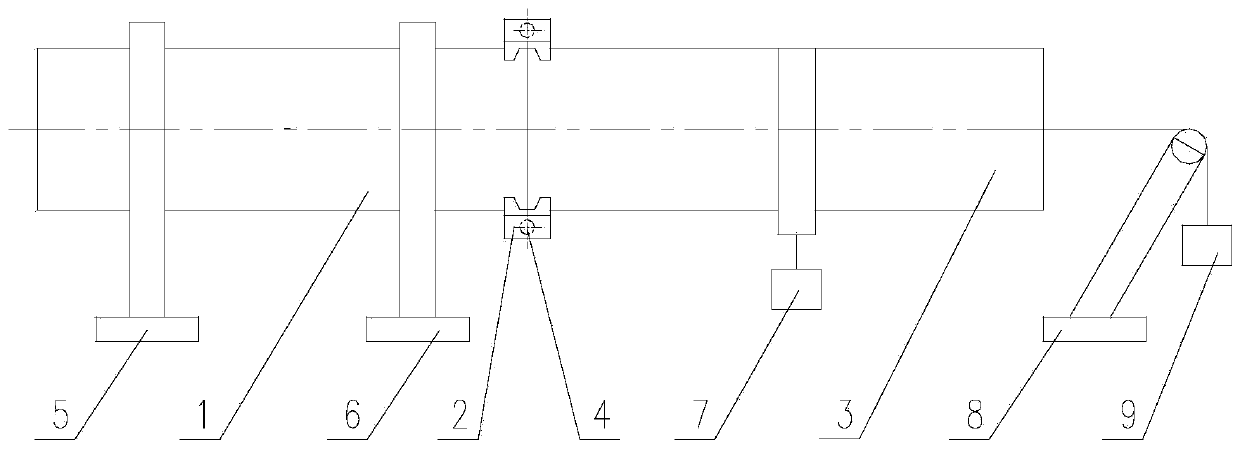

[0032] This embodiment provides a ground test simulation device for a separation device, see the attached image 3 , including: engine A1, engine B3, snap ring 2, explosion bolt 4, fixing bracket A5, fixing bracket B6, counterweight A7, roller bracket 8 and counterweight B9;

[0033] The snap ring 2 is composed of two semi-circular rings, and the two semi-circular rings are connected into a circular ring by two explosive bolts 4, or the snap ring 2 is composed of four 1 / 4 circular rings, and the four 1 / 4 circular rings are The ring is connected into a circular ring by four explosive bolts 4; the inner peripheral surface of the snap ring 2 is provided with two annular bosses; the engine A1 and the engine B3 both adopt a cylindrical hollow shell consistent with the actual engine shell shape, and the engine A1 The outer circumferential surface of the docking end with the engine B3 is processed with an annular card groove;

[0034] The snap ring 2 is set on the outside of the eng...

Embodiment 2

[0038] Since the bending moment experienced by the snap ring 2 is very small during the stage-to-stage separation of many aircraft, the bending moment experienced by the snap ring 2 can be ignored.

[0039] The ground test simulation device of a kind of separation device of present embodiment, see appendix Figure 4 , including: engine A1, engine B3, snap ring 2, explosion bolt 4, spreader 10 and counterweight C11;

[0040] The snap ring 2 is composed of two semi-circular rings, and the two semi-circular rings are connected into a circular ring by two explosive bolts 4, or the snap ring 2 is composed of four 1 / 4 circular rings, and the four 1 / 4 circular rings are The ring is connected into a circular ring by four explosive bolts 4; the inner peripheral surface of the snap ring 2 is provided with two annular bosses; the engine A1 and the engine B3 both adopt the cylindrical hollow shell of the engine, and the docking of the engine A1 and the engine B3 The outer peripheral surf...

Embodiment 3

[0044]On the basis of Example 1 or Example 2, for some engines with larger product quality and scale, use the cylindrical test piece A paired with the snap ring interface to replace the engine A1, and the cylindrical test piece A paired with the snap ring interface Part B replaces engine B3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com