High-precision finished die inspection device

A finished product inspection, high-precision technology, applied in the direction of the measuring device, the locking device and the instrument when the movable parts of the measuring device are not in use, it can solve the problem of low inspection accuracy of the equipment, achieve convenient installation, reduce the transmission space, improve the The effect of testing precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

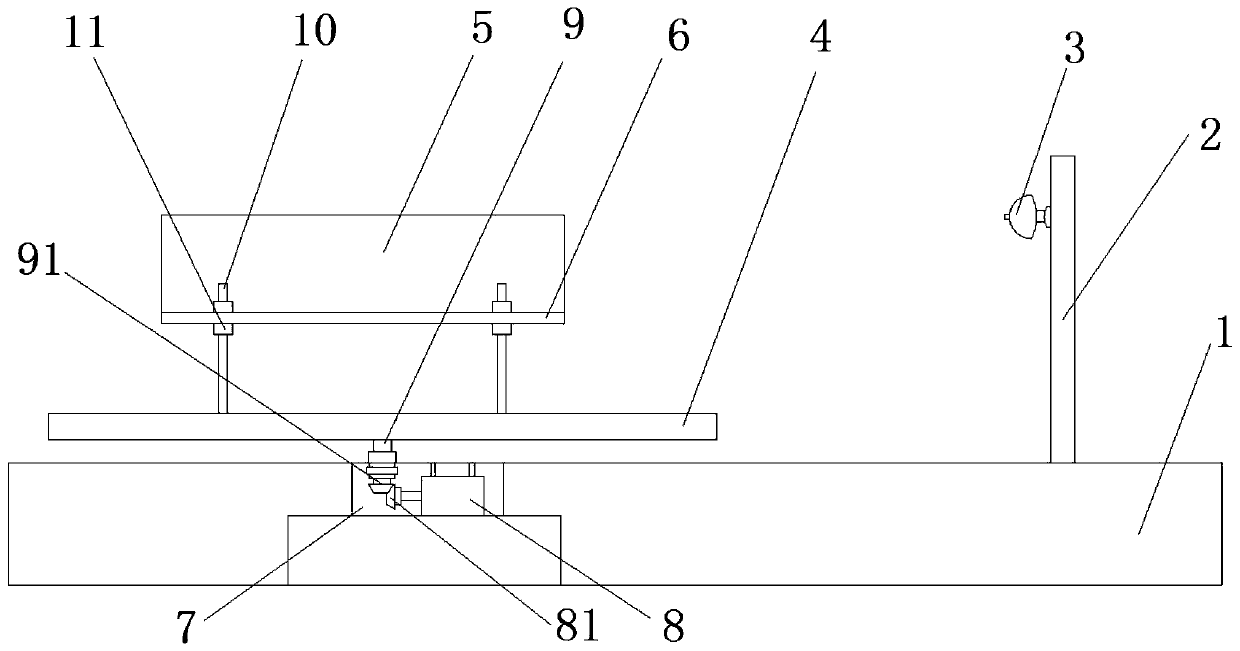

[0025] A high-precision mold product inspection device, including a base, a detection mechanism is installed on the base, the detection mechanism includes a mounting frame connected to the base, a detection probe is installed on the mounting frame, and a fixing mechanism is installed on the base next to the detection mechanism , the fixing mechanism includes a turntable installed on the base, a fixed seat is installed on the turntable, an organic box is installed in the base, a motor is arranged in the box, the output end of the motor is connected with a rotary shaft, and the other end of the rotary shaft is connected to the Turntable bottom connection. With this arrangement, the arc-shaped groove on the upper surface of the base can increase the contact area between the base and the mold, and can better carry the mold. The mounting plate can move up and down along the studs, and then fixed by fastening nuts, so as to realize the free adjustment of the height of the base, whic...

Embodiment 2

[0027] On the basis of Embodiment 1, the motor is arranged in the horizontal direction, the output shaft of the motor is connected with an output bevel gear, the rotating shaft is arranged in the vertical direction, and the end of the rotating shaft close to the motor side is connected with the output cone Gear meshing transmission bevel gears. Through this setting, the output bevel gear meshes with the transmission bevel gear for transmission, and then drives the rotary shaft to rotate. The rotary shaft and the output shaft of the motor are vertically arranged, which can reduce the transmission space and facilitate installation.

Embodiment 3

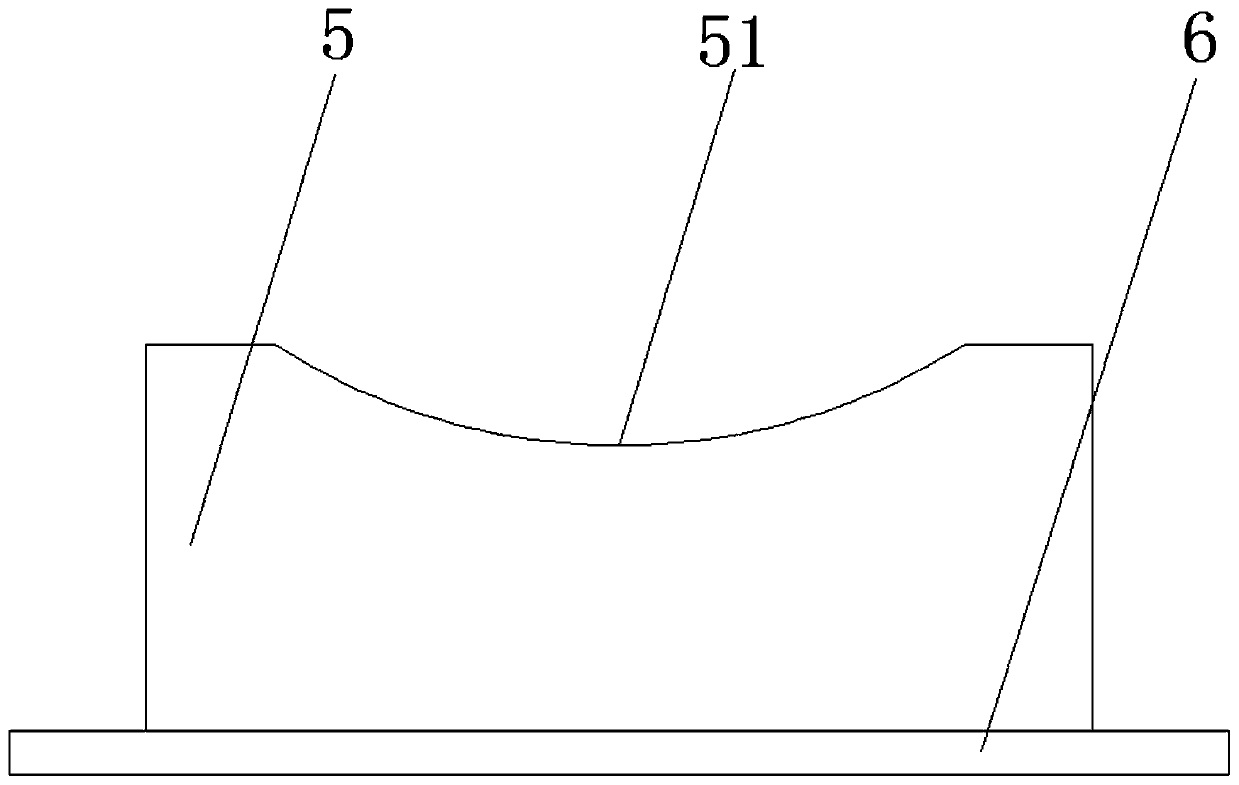

[0029] On the basis of the above-mentioned embodiments, the fixed seat includes a base, an arc-shaped groove is opened on the upper surface of the base, and a mounting plate is connected to the lower part of the base, and a number of through holes are opened on the mounting plate. For the studs, the mounting plate is sheathed on the studs through through holes, the studs are set with fastening nuts above and below the mounting plate, and the mounting plate is fixed on the studs through the fastening nuts. With this arrangement, the arc-shaped groove on the upper surface of the base can increase the contact area between the base and the mold, and can better carry the mold. The mounting plate can move up and down along the studs, and then fixed by fastening nuts, so as to realize the free adjustment of the height of the base, which is convenient for the detection probe to detect the mold from multiple angles, and effectively improves the inspection accuracy of the mold.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com