Convenient bending machine capable of dragging materials forwards in follow-up mode

A bending machine and dragging technology, which is applied in the field of bending machines, can solve the problems of inconvenient access and unfavorable work efficiency of staff, and achieve the effects of reducing the difficulty of storage, reducing the difficulty of taking and increasing the contact area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

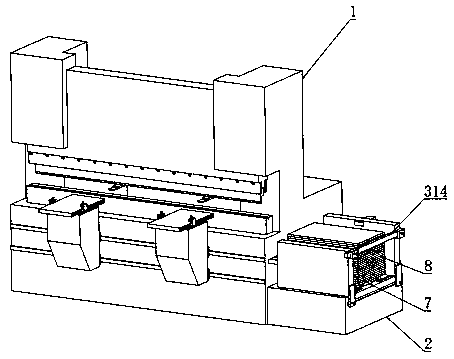

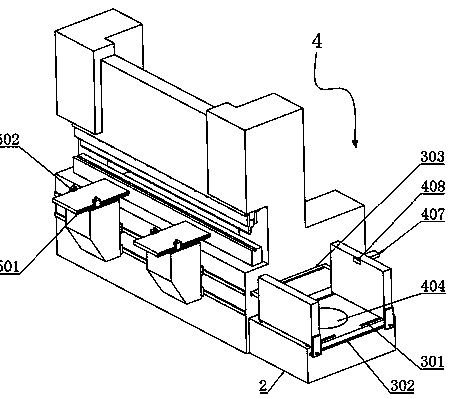

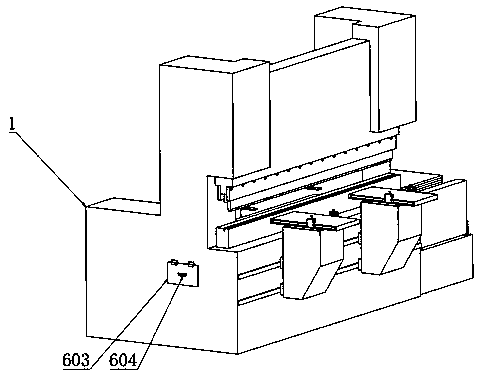

[0044] Example: such as Figure 1-8 As shown, the present invention provides a technical solution, a convenient bending machine for dragging materials before moving, including a body 1, a feeding table 2 is installed on the bottom of one end of the body 1, and first Limiting chute 301, fixed chute 302 is provided on the side top of feeding platform 2, second limiting chute 303 is provided in the middle part of one end of body 1, and first clamping baffle 304 is installed on the top side of feeding platform 2, feeding platform 2. A second clamping baffle 305 is installed on the other side of the top, and first limiting sliders 306 are installed on both sides of the first clamping baffle 304 and the bottom of the second clamping baffle 305. The sections of the block 306, the second limit slide 307, the first limit chute 301 and the second limit chute 303 are all T-shaped, and the first limit slide 306 is located inside the first limit chute 301, The second limit slider 307 is l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com