A non-destructive hole-making method for continuous fiber reinforced ceramic matrix composites

A technology of continuous fiber and composite materials, which is applied in the field of preparation of ceramic matrix composite materials, can solve problems affecting the performance of components, damage of continuous fibers, and reduction of mechanical properties of materials, so as to avoid defect damage, maintain structural integrity, and maintain mechanical properties. The effect of performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention is further described in detail below in conjunction with the accompanying drawings and the following embodiments:

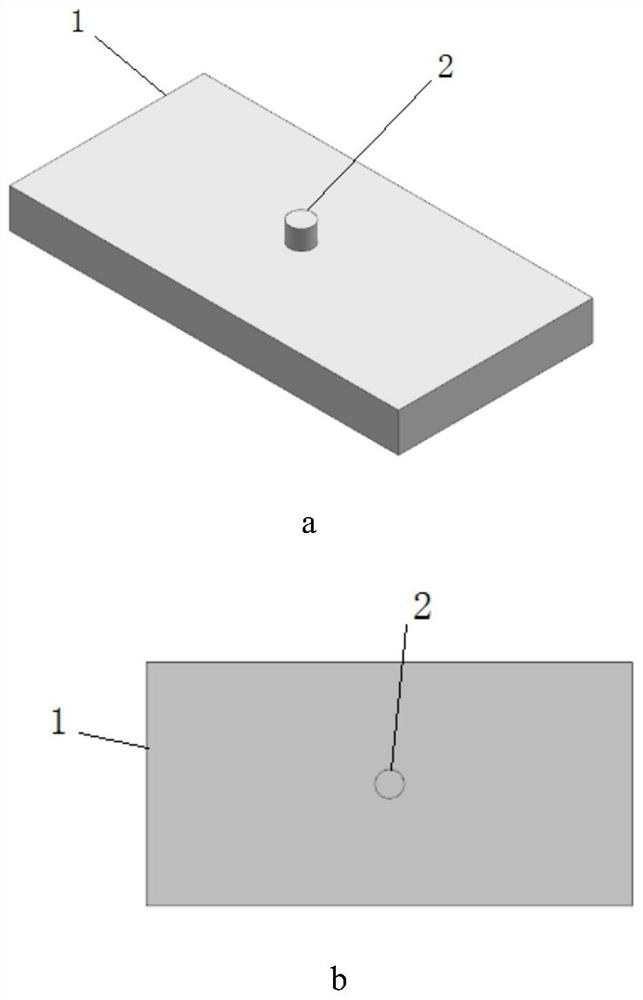

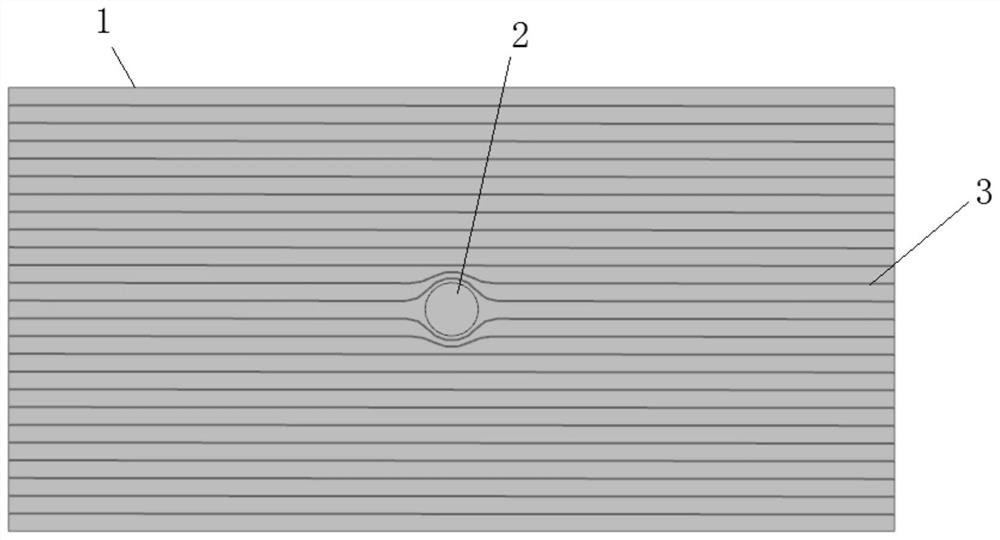

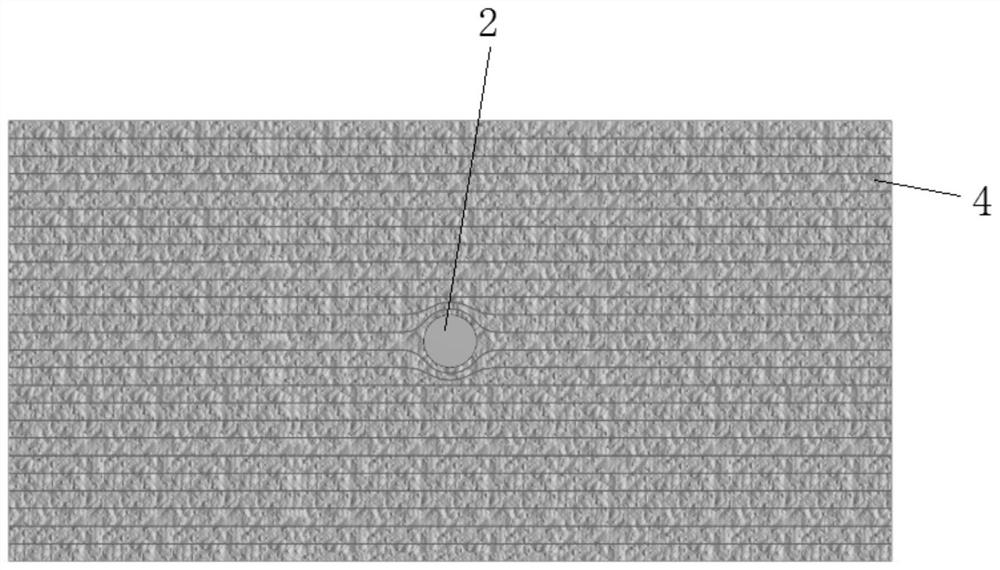

[0027] See attached Figures 1 to 4 As shown in the present embodiment, the size of the continuous silicon carbide fiber reinforced silicon carbide ceramic matrix composite flat member is 100mm×50mm×5mm, the central contains a diameter of 6mm straight hole 5, the steps of the continuous fiber reinforced ceramic matrix composite without injury making method are as follows:

[0028] Step 1, according to the size, shape and location requirements of hole 5, the design and preparation of fiber laying template 1, the size of fiber laying template 1 is 100mm×50mm× 10mm, fiber laying template 1 is set in the center of the prefill 2, the diameter of prefill 2 is 6mm, the thickness is 5mm, and the fiber laying template 1 and prefill 2 are formed by high-purity graphite;

[0029] Step two, the continuous silicon carbide fiber 3 in accordance with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com