Multifunctional stirring model test box and use method thereof

A model test and multi-functional technology, which is applied in the direction of basic structure test, construction, and basic structure engineering, etc., can solve the problems of cumbersome process, poor effect, long vibration process, etc., achieve reasonable experimental data, improve experimental efficiency, reduce dangerous effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Utilize test chamber of the present invention to simulate a diameter to be 300mm, the pile-forming effect of the mixing pile that length is 1m under three-dimensional stress state, concrete steps are as follows:

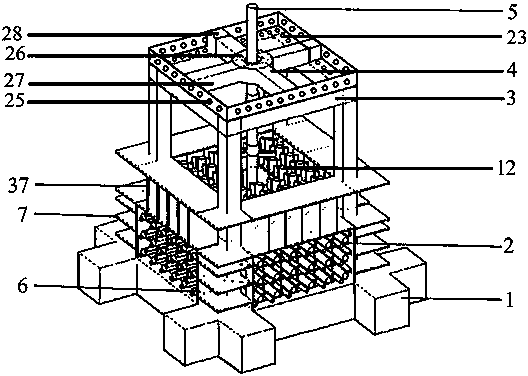

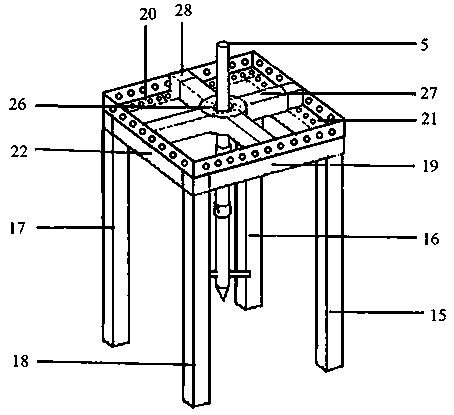

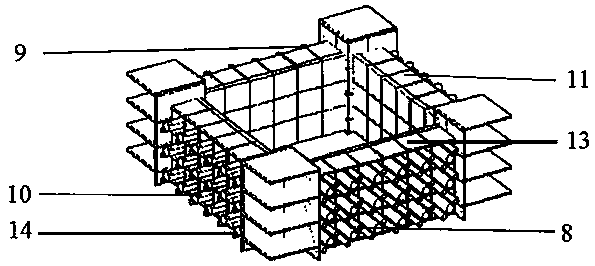

[0044] Such as Figure 1~7 As shown, a multifunctional mixing model test box is characterized in that it includes a base 1, a formwork system 2, a bracket 3, a fixing frame 4, a drill pipe 5, angle steel 6, and angle braces 7; the formwork system includes a front formwork 8. The rear template 9, the left template 10, the right template 11, and the top template 12, wherein, the front template 8, the rear template 9, the left template 10, the right template 11, and the top template 12 are provided with templates Support 13 and servo hydraulic jack 14, said support 3 includes a vertical bar structure and a horizontal bar structure, and the vertical bar structure includes No. 1 vertical bar 15, No. 2 vertical bar 16, No. 3 vertical bar 17, and No. 4 vertical bar 1...

Embodiment 2

[0071] Adopt a kind of multifunctional stirring model test box of the present invention and using method thereof to carry out test, the number of stirring piles is 5, and stirring diameter is 300mm, and stirring depth is 1m, and the pile-forming effect under three-dimensional stress state, The test process is as follows:

[0072] A multifunctional mixing model test box and its use method are tested. The number of mixing piles is 5, the mixing diameter is 300mm, and the mixing depth is 1m. The pile-forming effect under the three-dimensional stress state, the test process is as follows:

[0073]A multifunctional mixing model test box, characterized in that: it includes a base 1, a formwork system, a bracket 3, a fixing frame 4, a drill pipe 5, angle steel 6, and angle braces 7; the formwork system includes a front side formwork 8, a rear side Template 9, left template 10, right template 11, top template 12, wherein, front template 8, rear template 9, left template 10, right temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com