Rotary type American and French universal air nozzle

A technology of gas nozzle and American method, which is applied in the field of tire inflation, can solve the problems of heavy hand feeling, sharp edges, deformation of sealing rings of beautiful nozzle and French nozzle, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

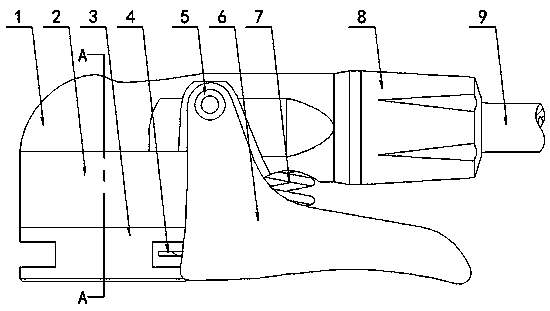

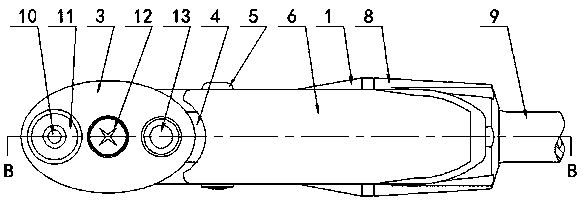

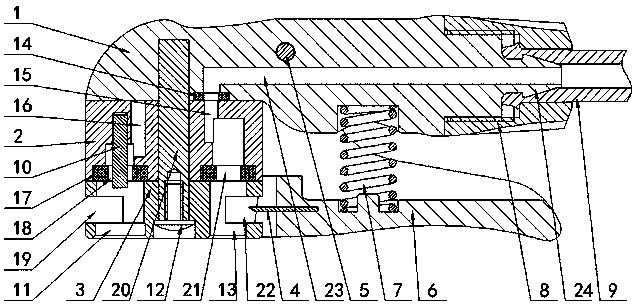

[0022] Figure 1 to Figure 7 As shown, it is a specific embodiment of the invention to create a rotary type American-French general-purpose air nozzle, which includes an air nozzle main body 1, a middle block 2, an air nozzle head 3, and an air nozzle pressing mechanism. The air nozzle main body 1 is provided with The air inlet channel 23 and the cylindrical pin 20, the middle block 2 and the valve head 3 are correspondingly provided with the center hole 27 of the middle block and the center hole 28 of the valve head. 28 and is rotatably sleeved on the cylindrical pin 20 through the screw 12; the middle block 2 is respectively provided with the French mouth air intake passage 15 and the beautiful mouth air intake passage 16 which are rotationally docked with the air intake passage 23 outlets, and the French mouth inlet passage Air channel 15 is connected to the French mouth air outlet 21 and the American mouth air outlet 18 connected to the American mouth air inlet passage 16....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com