Gear drive that eliminates backlash

A technology of gear transmission and clearance, applied in the direction of hoisting device, portable lifting device, belt/chain/gear, etc., can solve the problems of hanging spring, poor reliability of compression spring, inconvenient adjustment and replacement of spring, bias falling off, etc. The effect of stable and reliable adjustment, simple and reliable molding, and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, but not to limit the present invention.

[0022] Glossary

[0023] Center distance: usually refers to the center distance between two gear shafts.

[0024] Rotary positioning accuracy: Under the same conditions, the position accuracy of the object returning to its original position after moving.

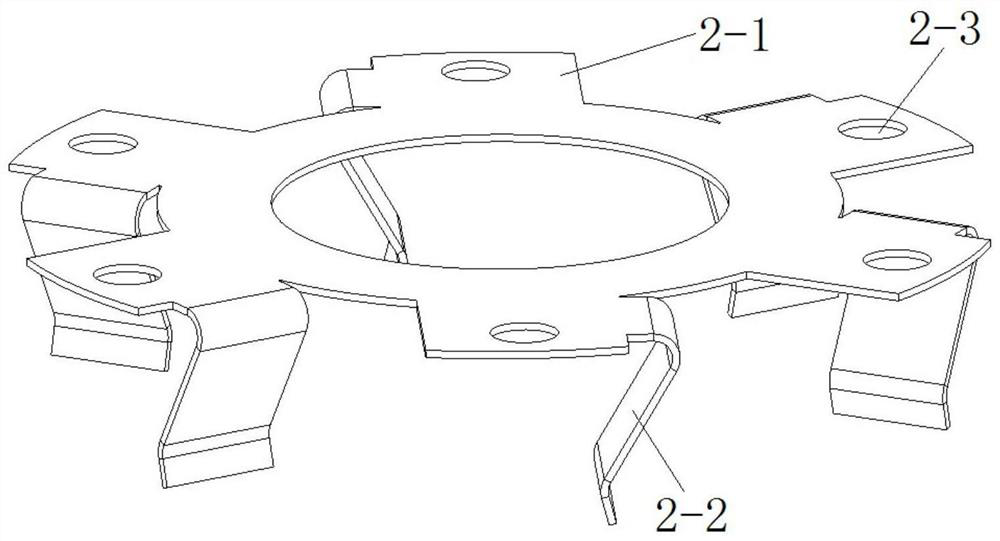

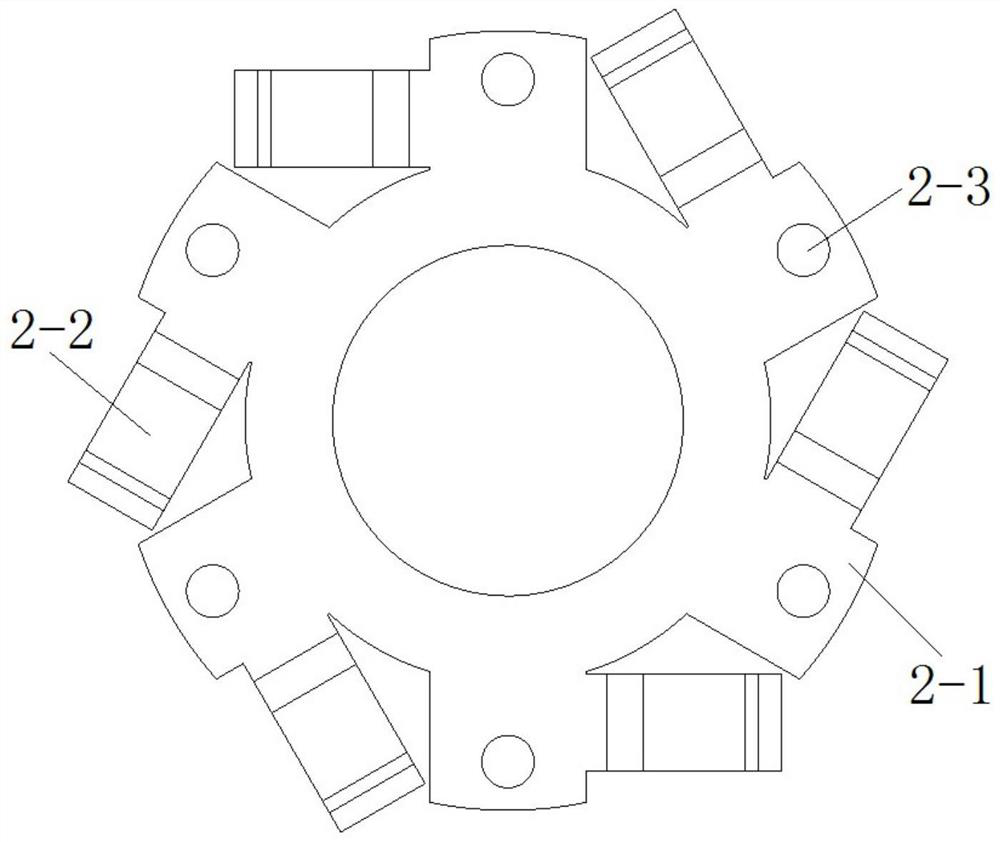

[0025] The invention provides a gear transmission device capable of eliminating backlash. The driven gear meshed with the driving gear is made into two pieces, and the two pieces of driven gear are staggered by a certain angle through a torsion spring plate, and then respectively connected with the driving gear. Mesh assembly forms...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

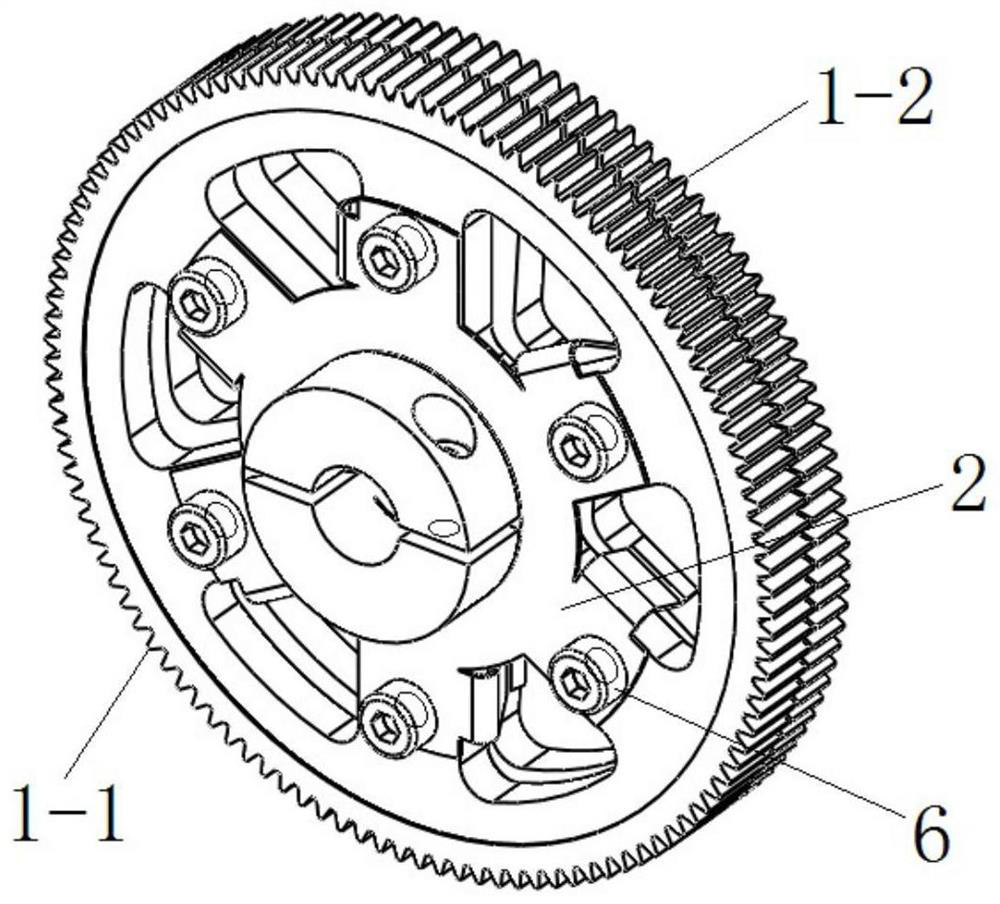

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com