Reversible swivel table device

A technology of rotary workbench and workbench, which is applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems of high manufacturing precision, low reliability, complex and huge gap elimination, etc., and achieve angle measurement accuracy Guarantee, improve rotary positioning accuracy, and reduce overall weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with accompanying drawing:

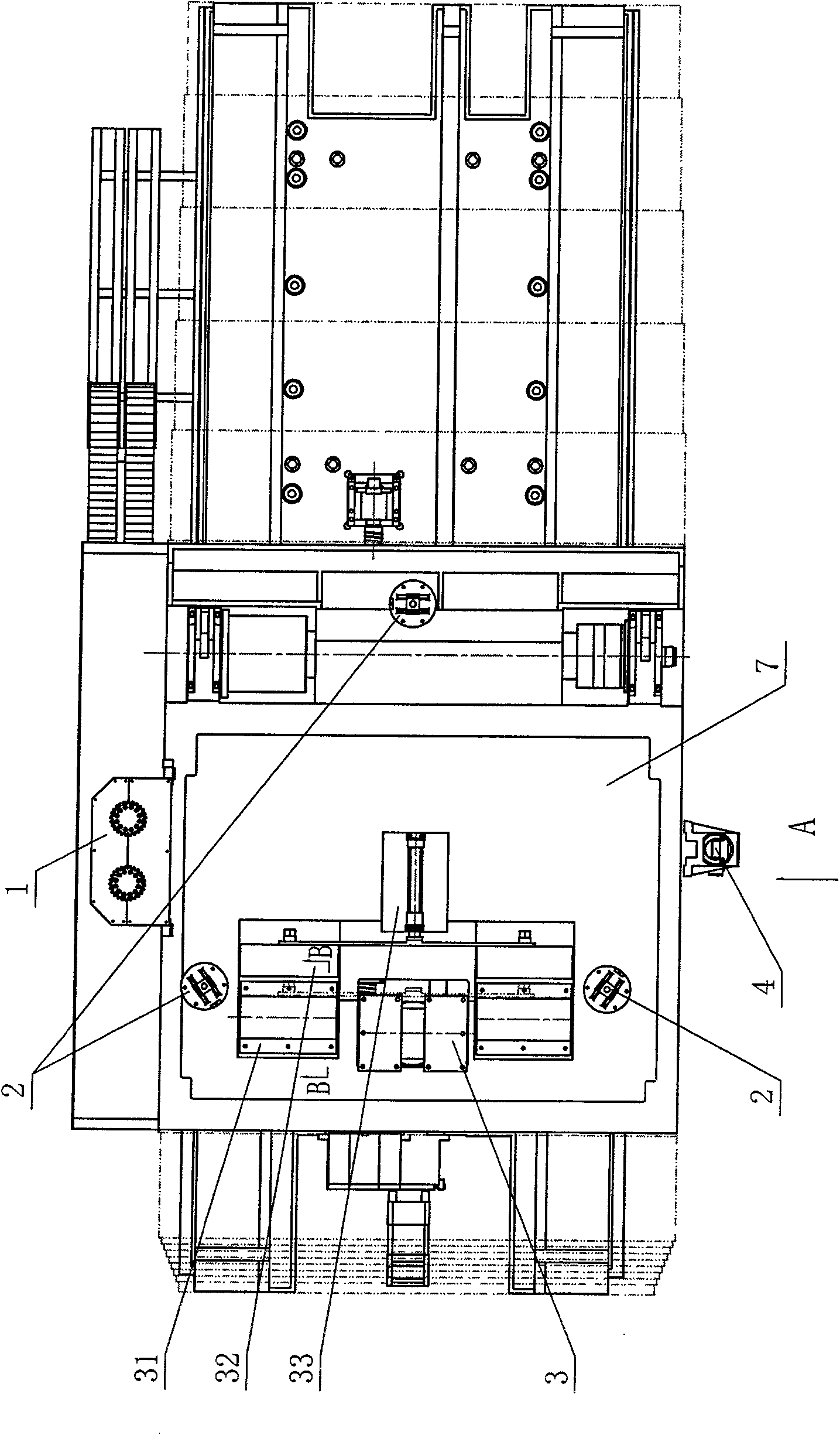

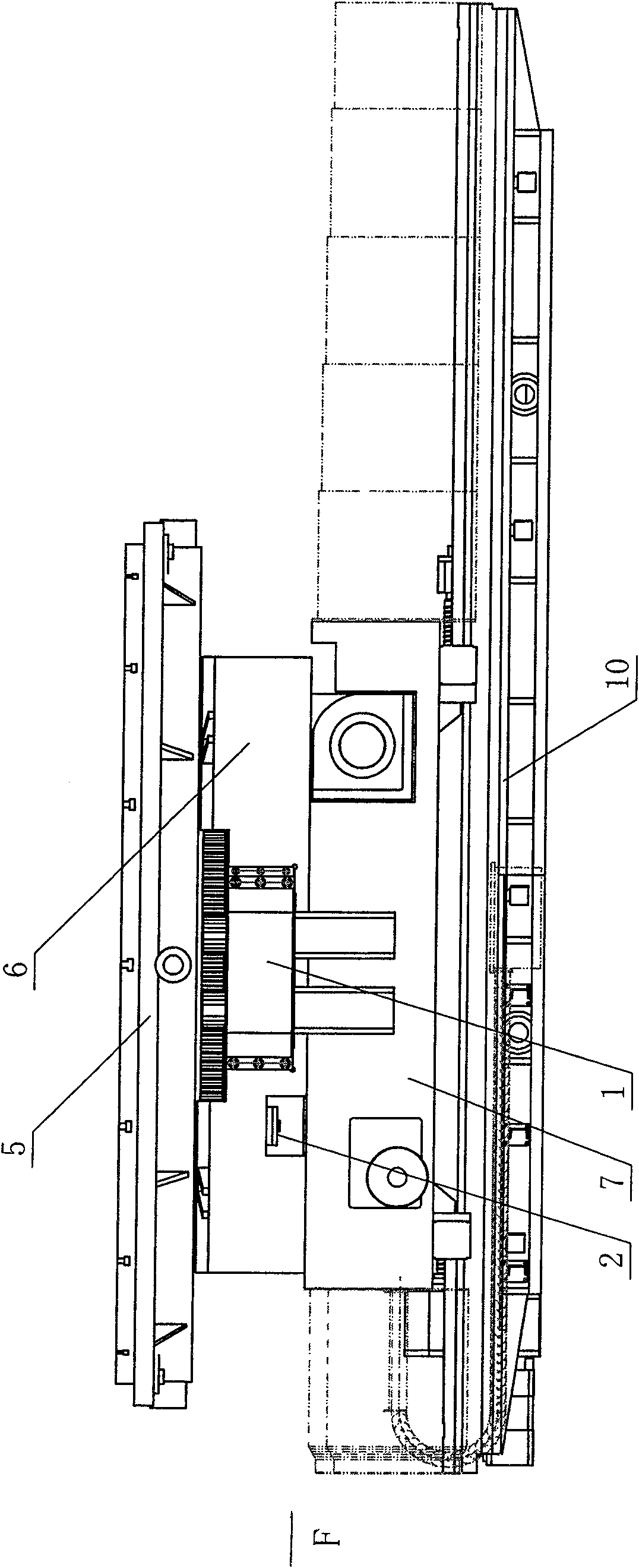

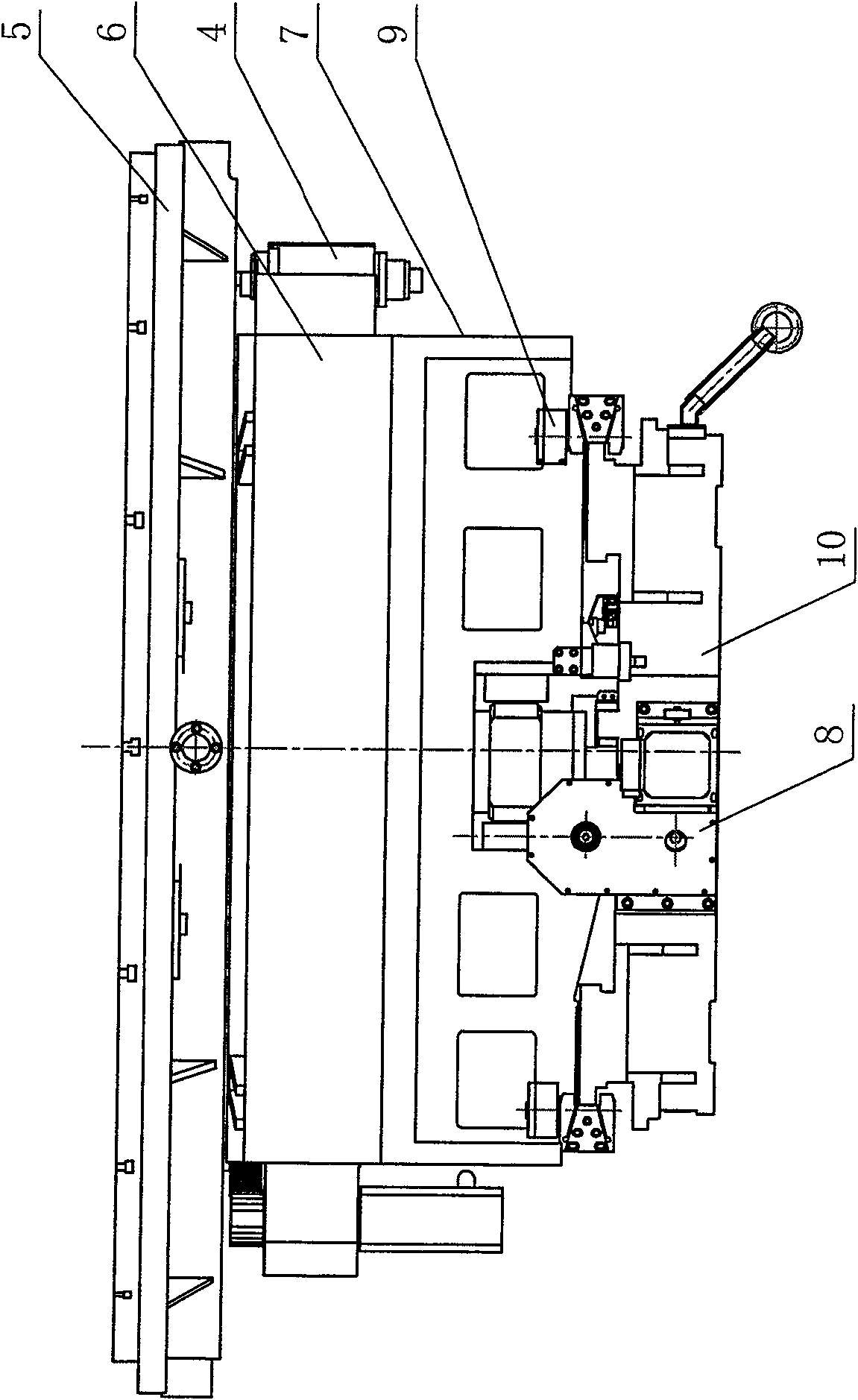

[0017] Depend on figure 1 combine figure 2 and image 3 As shown, a reversible rotary table device includes a rotary feed box 1, a worktable 5, a pedestal 6, and a bed 10. The bed 10 is integrated with the foundation through a large number of closed adjustable pad irons. The body 10 inside has a closed centralized oil return device, and the top of the bed 10 has a linear feed system. The linear feed system is a general double-nut ball screw, and the linear feed box 8 is at one end of the bed. The slide 7 is connected with the bed 10, and the horizontal guide rail connected between the slide 7 and the bed 10 is a closed static pressure guide rail, and the guide rail surface on the slide 7 is made of zinc-based wear-resistant alloy material. Two sets of linear clamping mechanisms 9 are respectively fixed at the two ends of the linear clamping mechanism 9, which are used f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com