A double-sided painting equipment for electric vehicle processing doors

A technology for painting equipment and electric vehicles, applied in the direction of spraying devices, liquid spraying devices, etc., it can solve the problems that the positioning rod is difficult to align with the positioning groove, the angle is inaccurate, and the operation is troublesome, so as to achieve accurate flipping angle and high degree of automation , the effect of reducing the workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

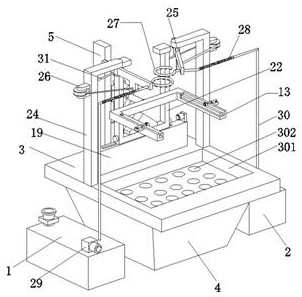

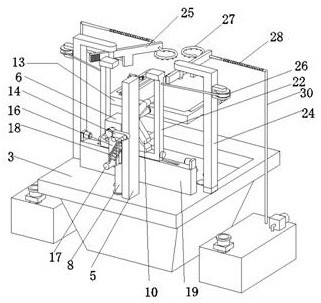

[0034] Embodiment 1 introduces a double-sided painting equipment used for processing electric vehicle doors. Reference attached figure 1 And attached figure 2 , its main structure includes spraying the first paint tank 1, the second paint tank 2 and the paint spraying platform 3, the first paint tank 1, the second paint tank 2 are respectively arranged on the left and right sides of the paint spraying platform 3, on the paint spraying platform 3 The lower end is provided with casing 4.

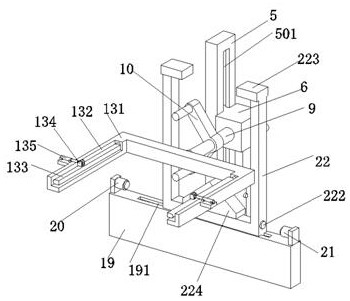

[0035] Reference attached figure 2 And attached image 3 , the rear end of the upper surface of the painting platform 3 is provided with a column 5, and one side of the column is provided with a vertical chute 501, and a lifting block 6 is provided on the side of the column 5 near the vertical chute 501, and on the side of the lifting block 6 A limit sliding block 7 is arranged on it, and its limit sliding block 7 can slide up and down along the vertical chute 501 . On the painting pla...

Embodiment 2

[0041] Embodiment 2 is a further improvement made on the basis of Embodiment 1. Its main improvements lie in absorbing the paint dispersed in the air during painting and improving the painting mechanism. Attached below figure 1 And attached Figure 6 Describe it in detail.

[0042] In Embodiment 2, the same parts as Embodiment 1 will not be described again. The differences include:

[0043] Reference attached figure 1 , a collection tank 301 is opened on the upper surface of the painting platform 3, a negative pressure air hole 302 is provided on the bottom wall of the collection tank 301, and a negative pressure induced draft fan (not shown in the figure) is provided inside the cabinet 4, and its negative pressure induced The air inlet of blower fan is communicated with negative pressure air hole 302; Present embodiment it draws the inside of cabinet 4 to negative pressure state by negative pressure induced draft fan, then changes the air flow direction below the automo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com