Active Compensation Low Eddy Current Axial Air Bearing

An air bearing and active compensation technology, which is applied in the direction of shafts and bearings, bearings, mechanical equipment, etc., can solve the problems of difficult execution, long cycle, and limited accuracy improvement, and achieve convenient execution, improve rotary positioning accuracy, and adjust The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

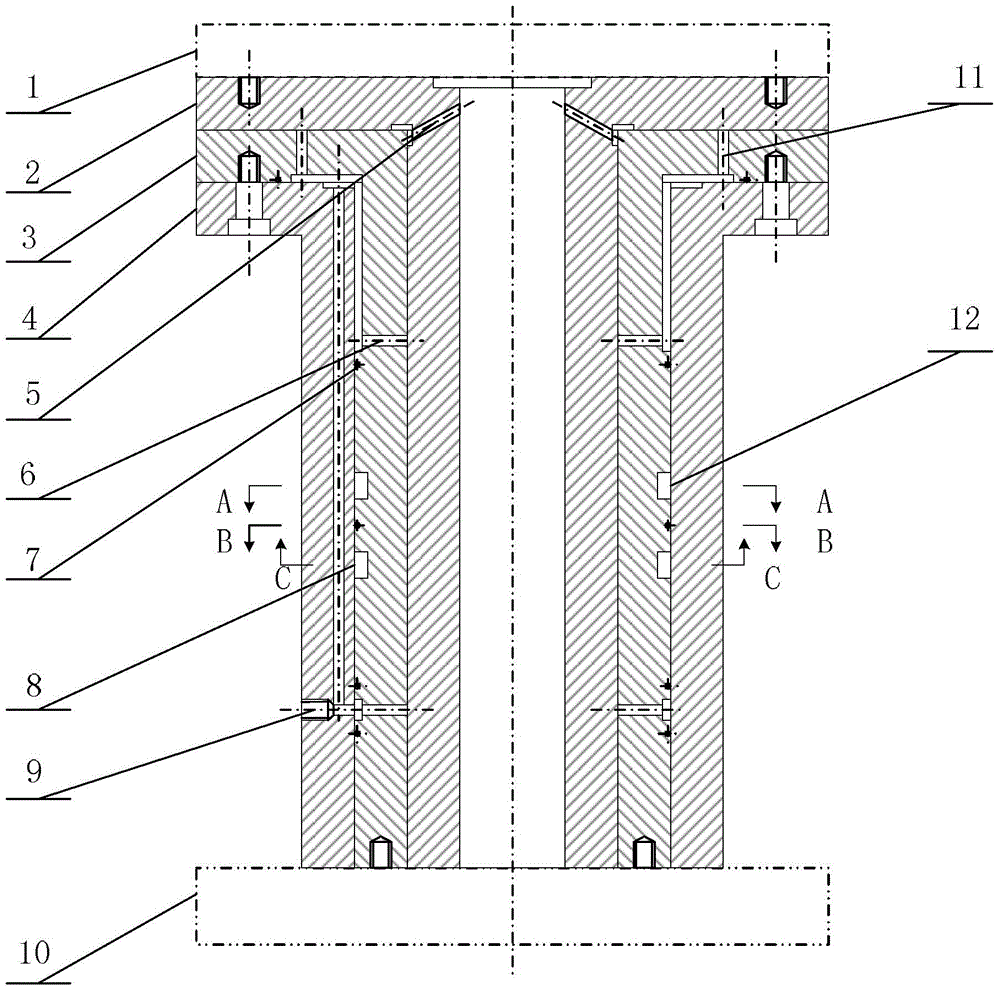

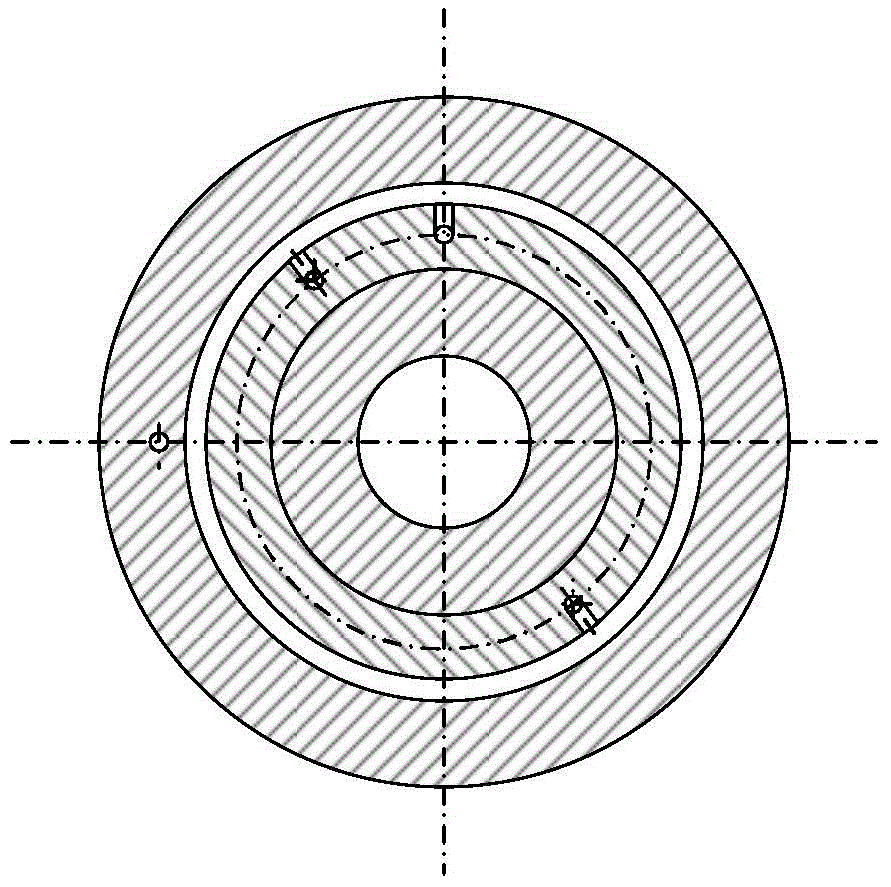

[0023] Specific implementation mode one: the following combination Figure 1 to Figure 4 Describe this embodiment, the active compensation type low eddy current axial motion air bearing in this embodiment, the air bearing is installed between the load 1 and the base 10, and is used to realize the high precision of the load 1 relative to the base 10 rotary motion;

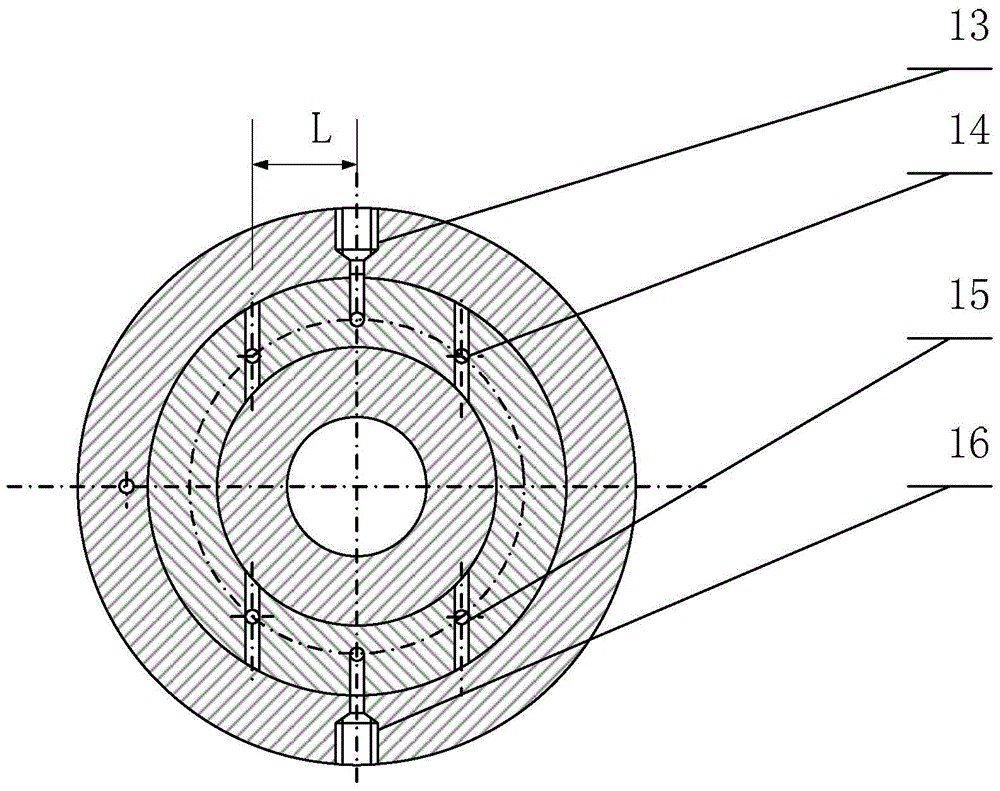

[0024] The air bearing includes an air bearing shaft 2, an air bearing sleeve 3, an air sealing sleeve 4, a vent hole 5, a radial orifice 6, an O-ring 7, a clockwise active vortex air supply chamber 8, and an air bearing. Floating bearing air supply hole 9, thrust surface throttle hole 11, counterclockwise active vortex air supply cavity 12, counterclockwise active vortex air supply hole 13, counterclockwise active vortex non-radial orifice 14, clockwise active vortex non-radial To the orifice 15 and the clockwise active swirl air supply hole 16,

[0025] The air bearing shaft 2 is a T-shaped shaft or an I-shaped ...

specific Embodiment approach 2

[0035] Embodiment 2: This embodiment further describes Embodiment 1. The load 1 is a rotor of a turntable or a rotating shaft of a precision shafting system.

specific Embodiment approach 3

[0036] Embodiment 3: This embodiment further describes Embodiment 1 or 2. The base 10 is the peripheral structure of the table body of the precision turntable or the housing of the precision shafting system.

[0037] Combine below Figure 5 Interference eddy current moment compensation method of the present invention is described:

[0038] According to the geometric dimensions and tooling conditions of the air bearing, the empirical value T of the air bearing disturbance torque is given, and the parameters M, N and L are designed so that the active eddy current Ta≥1.5T is generated by the non-meridional orifice of the active eddy current.

[0039] The disturbance eddy current compensation process of the air bearing is as follows:

[0040] Step 1. Complete the processing and assembly of each part of the air bearing;

[0041] Step 2. Ventilate the radial orifice of the air bearing and the orifice of the thrust surface, and observe whether the air bearing rotates by itself;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com