Variable-focus liquid crystal lens of arc-shaped columnar cavity and electrode

A liquid crystal lens and electrode technology, which is applied in nonlinear optics, instruments, optics, etc., can solve the problems of large driving voltage of zoom liquid crystal lens, insufficient focusing range, and insufficient response speed, etc. Facilitates through-focus, simple-structured effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

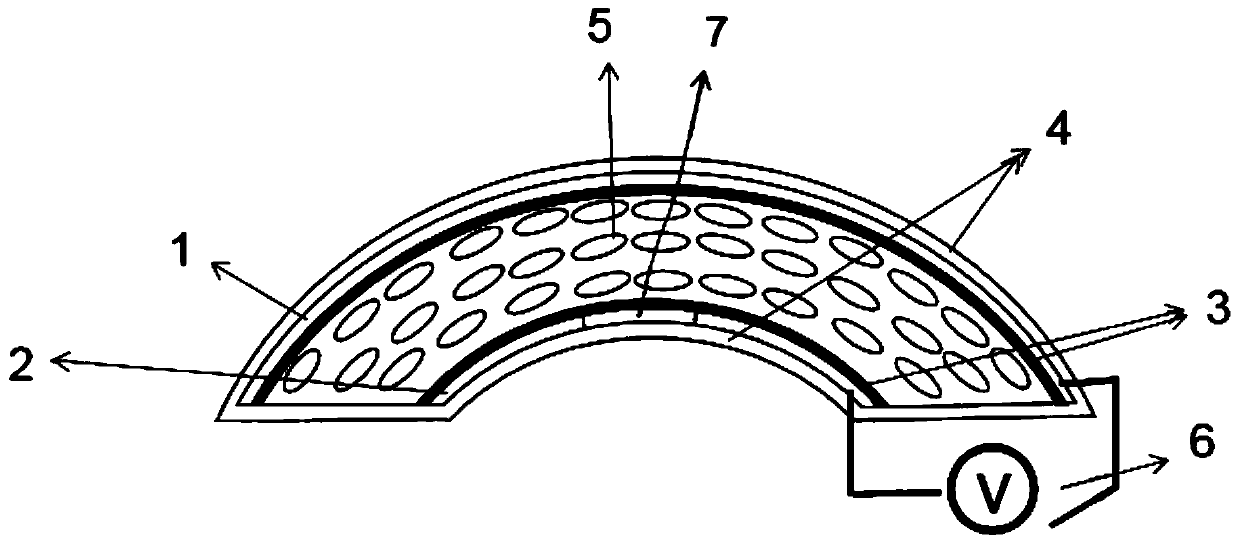

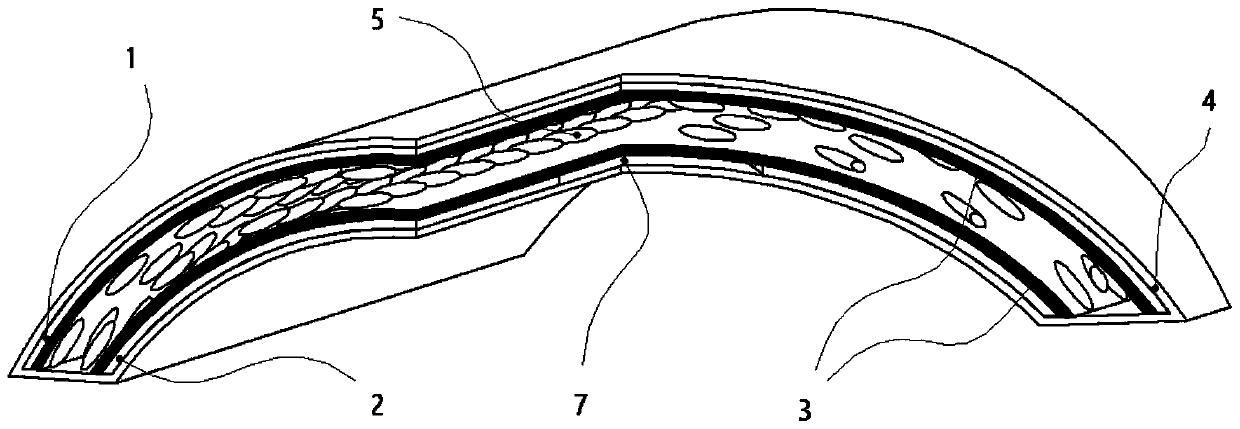

[0027] Such as Figure 1 to Figure 4 As shown, this embodiment discloses a variable-focus liquid crystal lens with an arc-shaped columnar cavity and electrodes, which mainly includes a protective case 4, a drive module 6, and an upper electrode 1, a lower electrode 2, and a liquid crystal lens arranged in the protective case 4. Alignment layer 3 and liquid crystal 5. The protective shell 4 adopts an arc-shaped arch structure design, and the cross-section is hollow and ring-shaped. The protective shell 4 is also provided with a cavity for filling the liquid crystal 5 . The upper electrode 1 is arranged in the cavity of the protective case 4 , on the upper wall of the cavity, and arranged in an arc along the cavity. The lower electrode 2 is arranged in the cavity of the protective shell 4, located on the lower wall of the cavity, and arranged along the arc of the cavity. The liquid crystal alignment layer 3 is arranged on the upper electrode 1 and the lower electrode 2 respect...

Embodiment 2

[0034] The purpose of this embodiment is to provide a variable-focus liquid crystal lens, the interior of which is arc-shaped columnar and filled with liquid crystal 5, so that the molecules of liquid crystal 5 have a certain deflection angle when no electric field is applied, which is used for the liquid crystal 5 molecules after the subsequent application of an electric field. The steering provides a larger angle, which can also reduce the driving voltage and improve the response speed of the liquid crystal lens to a certain extent. At the same time, the way of laying the electrodes is changed to arc-shaped columnar hole 7 electrodes, so as to achieve the effect of reducing the volume of the liquid crystal lens.

[0035] The technical scheme that present embodiment adopts is as follows:

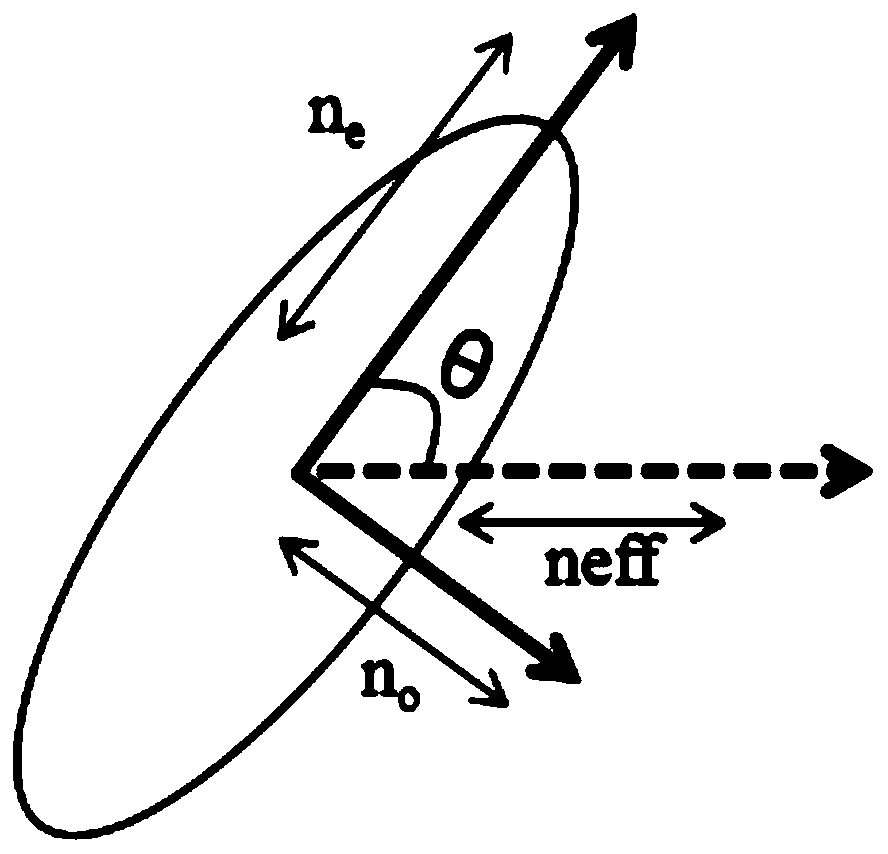

[0036] A variable-focus liquid crystal lens, the lens comprising: an upper electrode 1, a lower electrode 2, an upper and lower PI layer (liquid crystal alignment layer 3), a glass protecti...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap