Strength evaluation method based on minimum reliable safety coefficient

A technology of safety factor and determination method, which is applied in the field of strength assessment of mechanical structures, can solve problems such as design redundancy, and achieve the effect of avoiding design redundancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

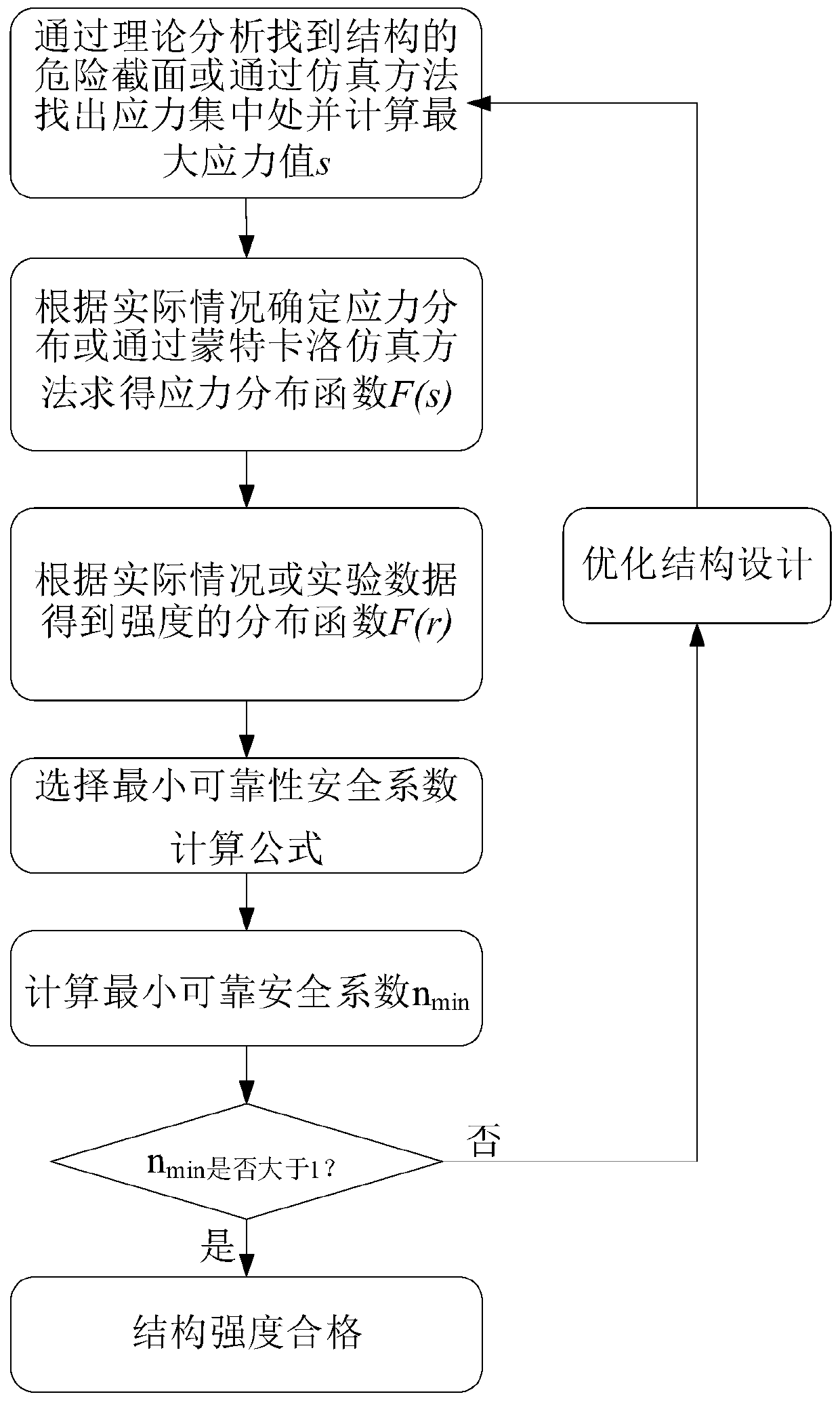

Method used

Image

Examples

Embodiment Construction

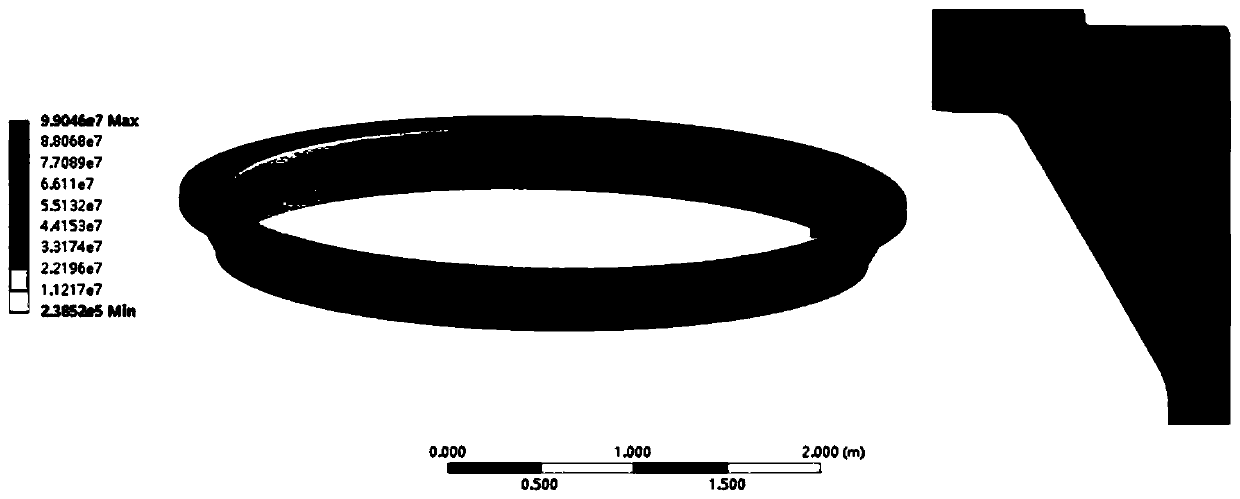

[0069] The following will combine figure 1 With a certain type of pressure vessel equipment flange strength evaluation case, the present invention is further described in detail, and the specific process is as follows:

[0070] (1) Use the numerical simulation method to analyze the static structure of the flange, the results are as follows figure 2 , according to the ASME standard under the design conditions, the strength evaluation of the flange mainly considers the influence of the primary overall film stress and the primary bending stress, and the stress needs to be linearized, and four stress linearization paths are set at the stress concentration. The primary film stress and primary film stress+bending stress peak values of the four paths are shown in Table 2. On path 1, P m and P m +P b The largest, respectively 5.7604Mpa and 21.679Mpa.

[0071] Table 2 Stress level of each path of the flange

[0072]

[0073] (2) To solve the minimum reliable safety factor, i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com