Air bag type vertical winding wire tensioning device and method

A tensioning device and airbag technology, applied in the field of transformer manufacturing, can solve problems such as hidden quality risks, damage to wire insulation, difficult operation, etc., and achieve the effects of practical and reliable operation, improving production efficiency and ensuring product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

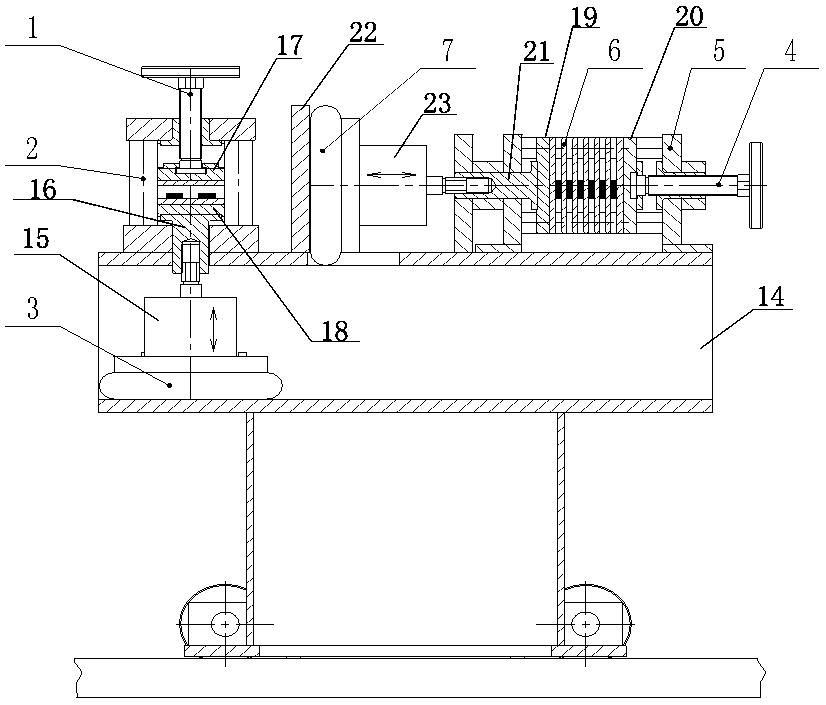

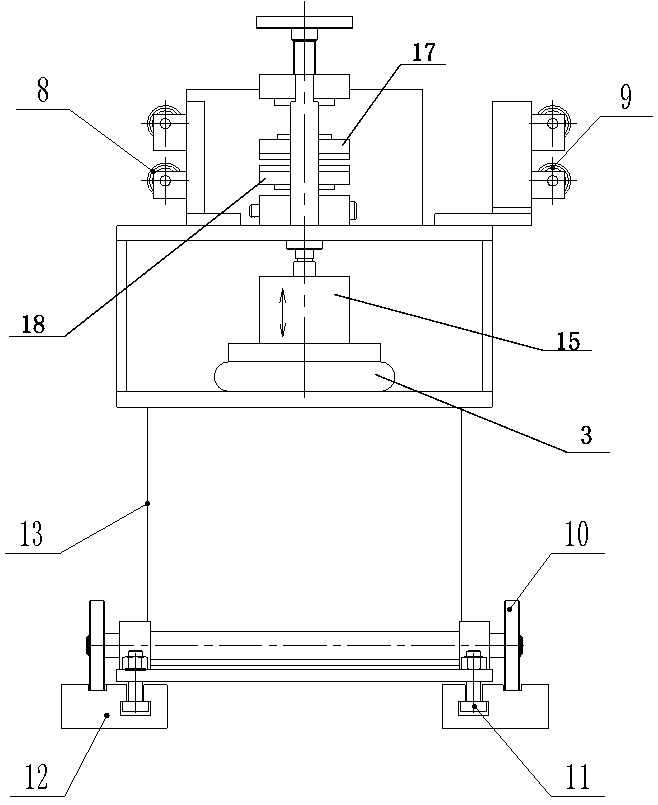

[0021] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0022] An airbag type vertical winding wire tensioning device, comprising a vertical airbag pressing device, a horizontal airbag pressing device, a frame body 13 and a working platform 14, the upper end of the frame body 13 is provided with a working platform 14, and the working platform 14 is rectangular The cavity structure, the vertical airbag pressing device is installed vertically on the working platform 14, and the horizontal airbag pressing device is installed horizontally on the working platform 14;

[0023] Described vertical air bag pressing device comprises vertical manual pretensioning device 1, vertical pressing support 2, vertical pressing air bag mechanism, slide block one 16, upper nylon pressing plate 17 and lower nylon pressing plate 18, described vertical pressing support 2 sets On the upper end su...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap