Motor rotor and reluctance motor

A motor rotor and reluctance technology, applied in the magnetic circuit, electric components, electrical components, etc., can solve the problems of motor performance decline, limit the use range of the motor, increase and decrease the output torque of the motor, etc. The effect of large use range and torque increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

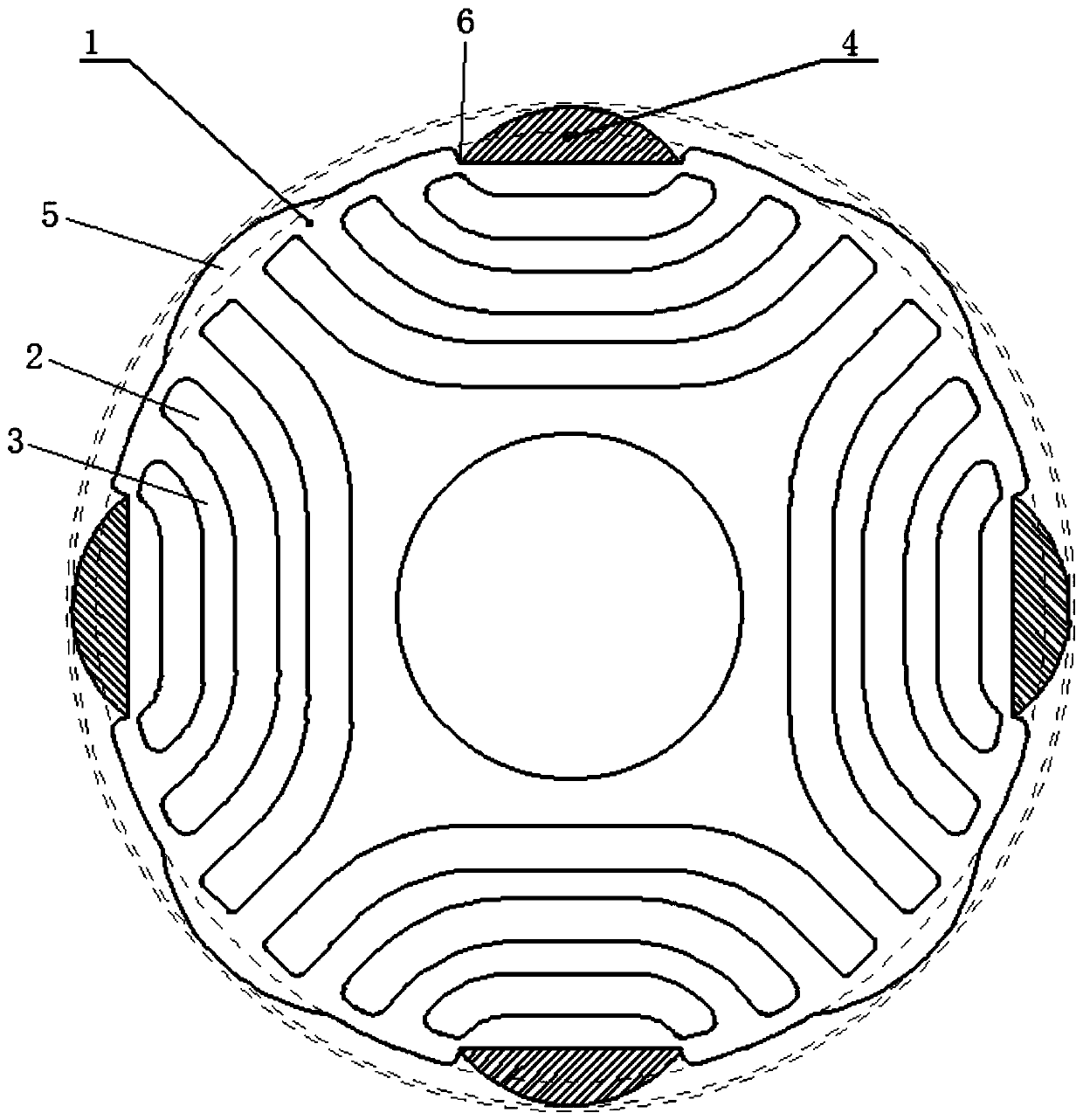

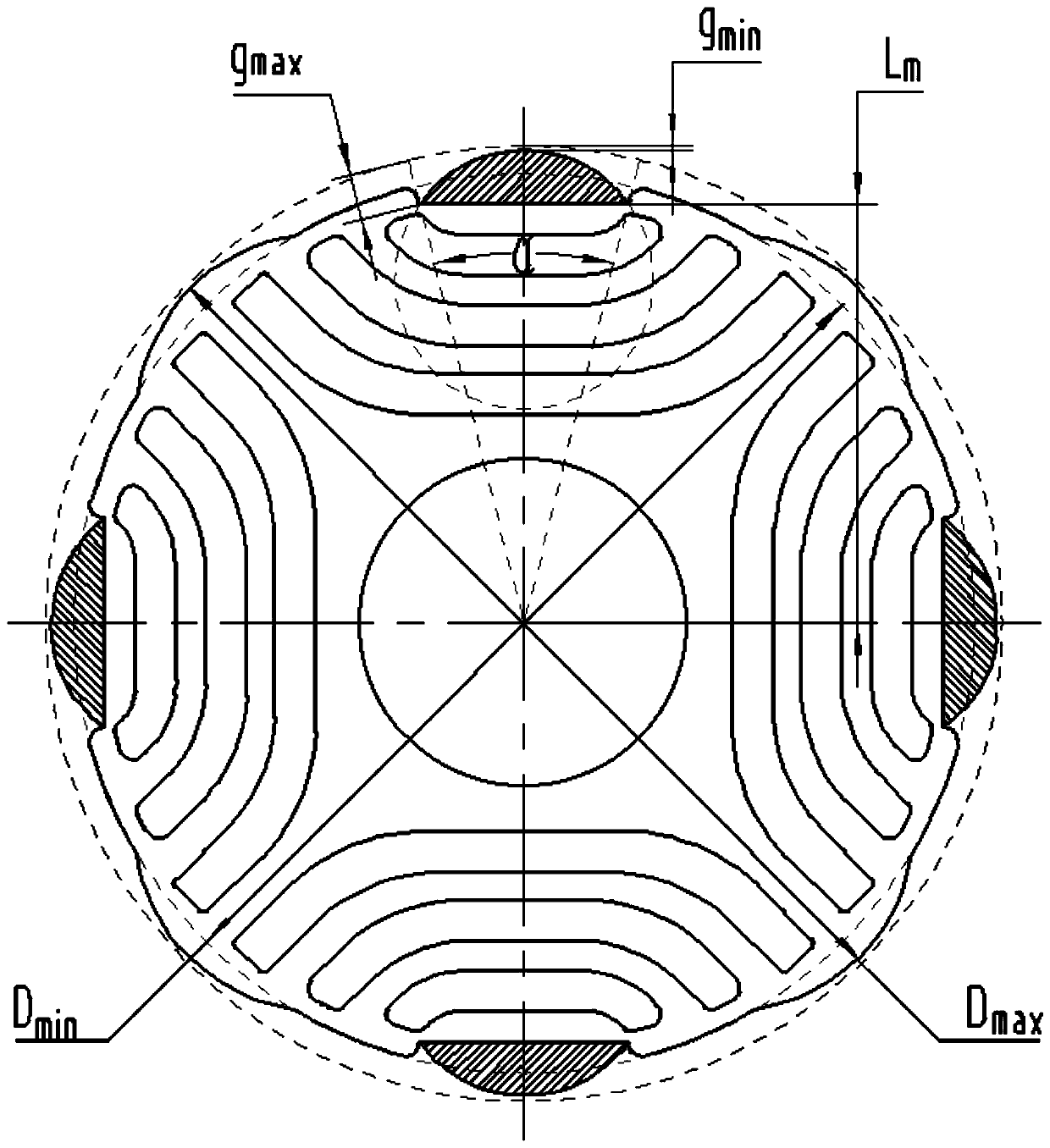

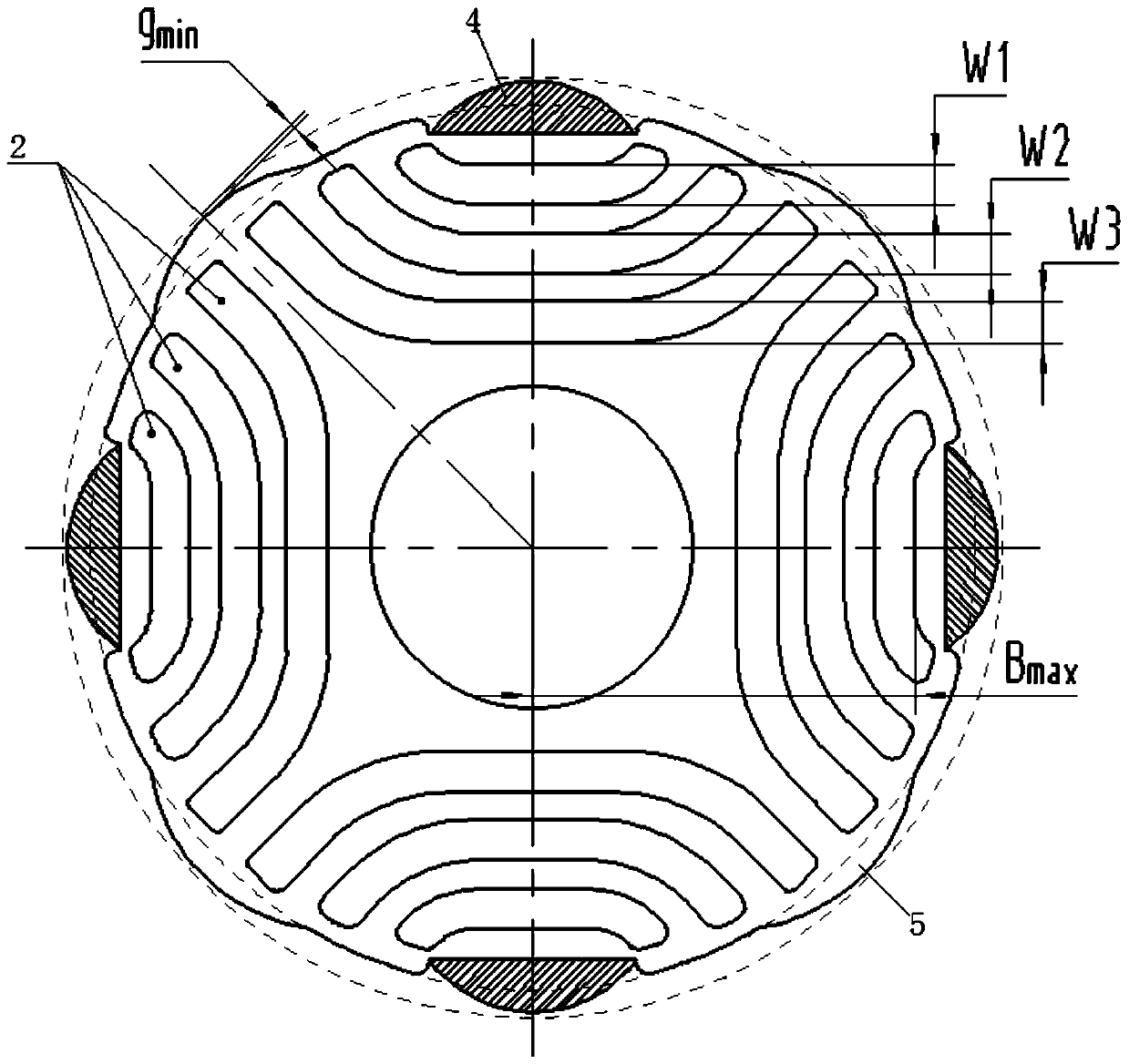

[0027] see in conjunction Figure 1 to Figure 5 As shown, according to the embodiment of the present application, the motor rotor includes a rotor core 1, and the rotor core 1 includes a plurality of magnetic barrier groups arranged in the circumferential direction, and each magnetic barrier group includes at least two magnetic barrier groups arranged at intervals in the radial direction. Through barriers 2, a magnetic conduction channel 3 is formed between adjacent magnetic flux barriers 2, and a radially magnetized permanent magnet 4 is attached to the outer peripheral wall of the rotor core 1. Under the same pole, the d-axis of the permanent magnet 4 is aligned with the The reluctance q-axis coincides.

[0028] In this application, the position of the permanent magnet 4 arranged on the outer peripheral wall of the rotor core 1 is optimized so that the d-axis of the permanent magnet 4 coincides with the reluctance q-axis, so that the permanent magnet 4 can be located on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com