Spring plate

A spring plate, vehicle suspension technology, applied in springs, vehicle springs, springs/shock absorbers, etc., can solve problems such as complex structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

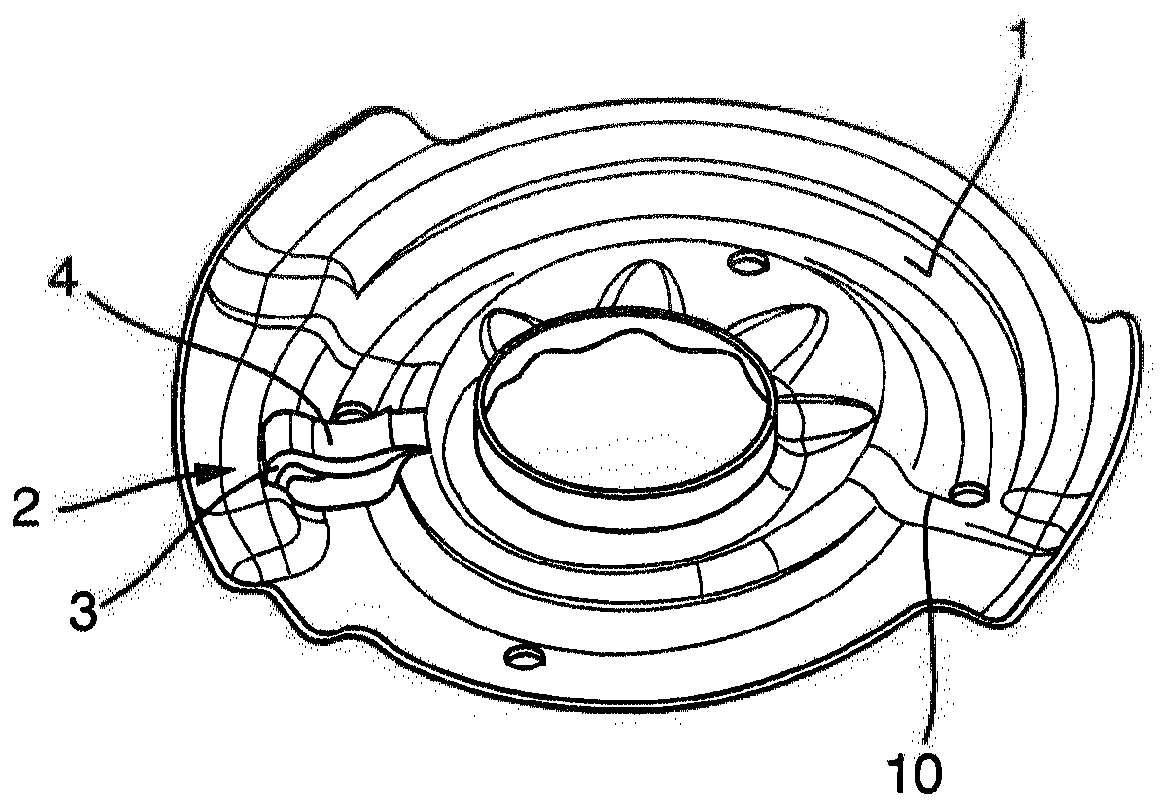

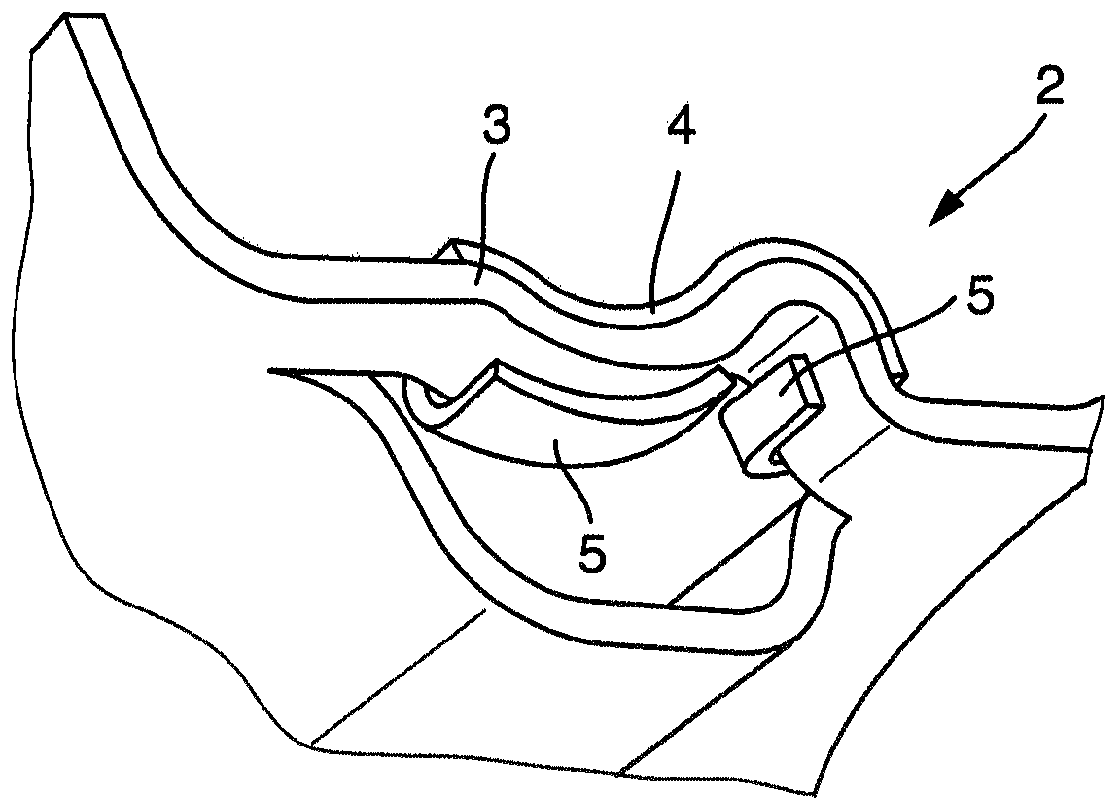

[0017] figure 1 A spring plate according to the invention is shown, wherein the surface 1 facing the vehicle suspension spring (not shown) is shown in perspective. The surface 1 has an end stop 10 on which the end face of the vehicle suspension spring formed as a helical compression spring is supported during operation. Furthermore, there is a region 3 extending from the spring plate material and forming a defined support point for a vehicle suspension spring (not shown). In the exemplary embodiment shown, the spring plate is produced from a sheet metal semi-finished product by forming, and the extension area is also produced by forming.

[0018] The extension area 3 has the form of a bridge and supports a sheet metal element 4 acting as a corrosion protection element. Thus, the sheet metal element 4 is arranged on the support point 2 and is in contact with the spring in all operating states, ie in particular in all spring deflection states of the vehicle suspension spring. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com