Metal-to-metal sealing structure of premium thread of oil well pipe for high-performance screwed joint

A threaded joint and metal sealing technology, applied in the direction of drill pipe, casing, drilling equipment, etc., can solve the problems of oil well pipe sealing ability decline, oil well pipe service life decline, marine environmental pollution, etc., to achieve uniform and reasonable force, prolong The effect of service life and large contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

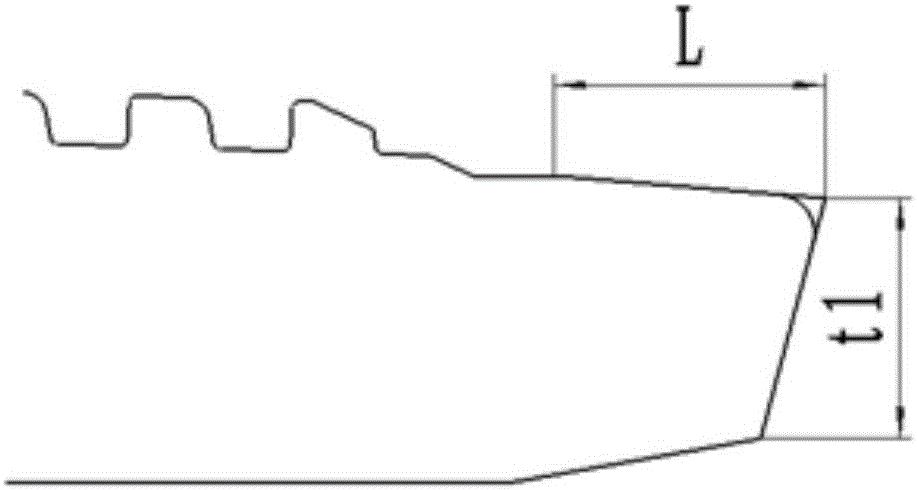

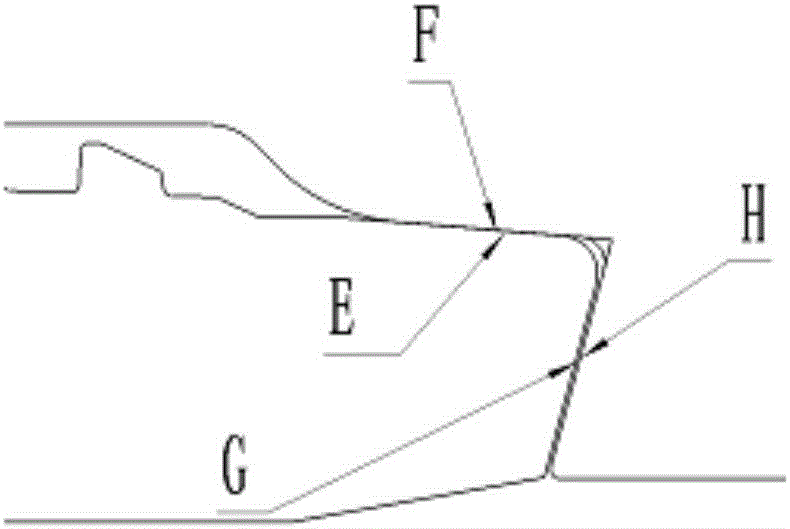

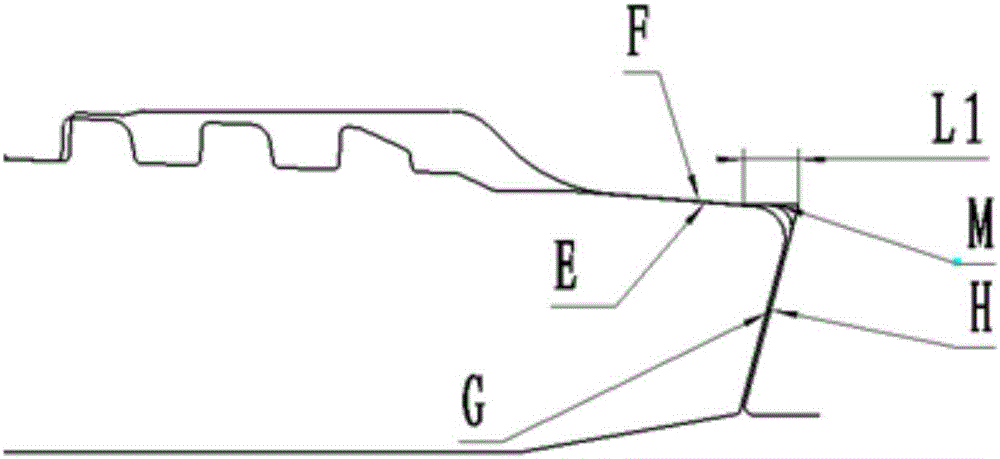

[0030] The metal-to-metal sealing structure of the special buckle oil well pipe used for high-performance threaded joints of the present invention is described in conjunction with the accompanying drawings.

[0031] The design idea of the metal-to-metal sealing structure of the special buckle oil well pipe used for high-performance threaded joints of the present invention is that the metal-to-metal sealing parts of the coupling B and the pipe body A adopt a single-stage to multi-stage sealing structure to produce multiple sealing protection effects , This kind of multi-stage sealing structure is especially suitable for thick-walled oil well pipes. Finally, through the screwing of the coupling and the pipe body, the two shoulders are connected to the top, and the sealing parts are tightly attached to realize the sealing function. Through the pipe body A and the coupling B, the male thread sealing shoulder G of the pipe body and the female thread sealing shoulder H of the pipe ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com