Odor adsorption material for refuse landfill, adsorption system and preparation method

A landfill and adsorption material technology, applied in the field of waste landfill, can solve the problems of loss of gas-holding function and increase, and achieve the effects of improving permeability, suppressing the generation of H2S, and improving the ability of gas collection and drainage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] The present invention will be described in detail below in conjunction with the accompanying drawings and specific implementation methods. It is necessary to point out that the schematic embodiments and descriptions of the present invention are only used to further explain the present invention, and cannot be interpreted as limiting the protection scope of the present invention. Those skilled in the art can make some non-essential improvements and adjustments based on the content of the present invention above.

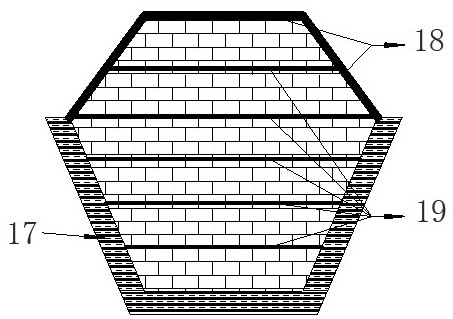

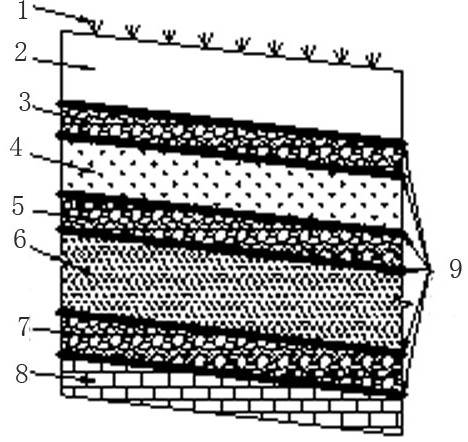

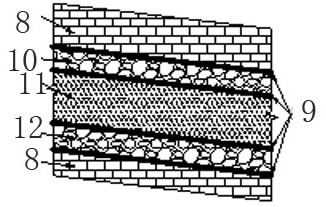

[0070] like Figure 1-Figure 7 Shown is a kind of odor adsorption material for landfill. The raw material is recycled fine material. The recycled fine material is made by mixing recycled fine aggregate and recycled powder prepared by recycling construction waste, and the recycled fine aggregate and recycled powder are prepared. Concrete and mortar account for more than 95% of the construction waste, and the particle size distribution curve of the odor adsorptio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com