Patents

Literature

32results about How to "Guaranteed replaceability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

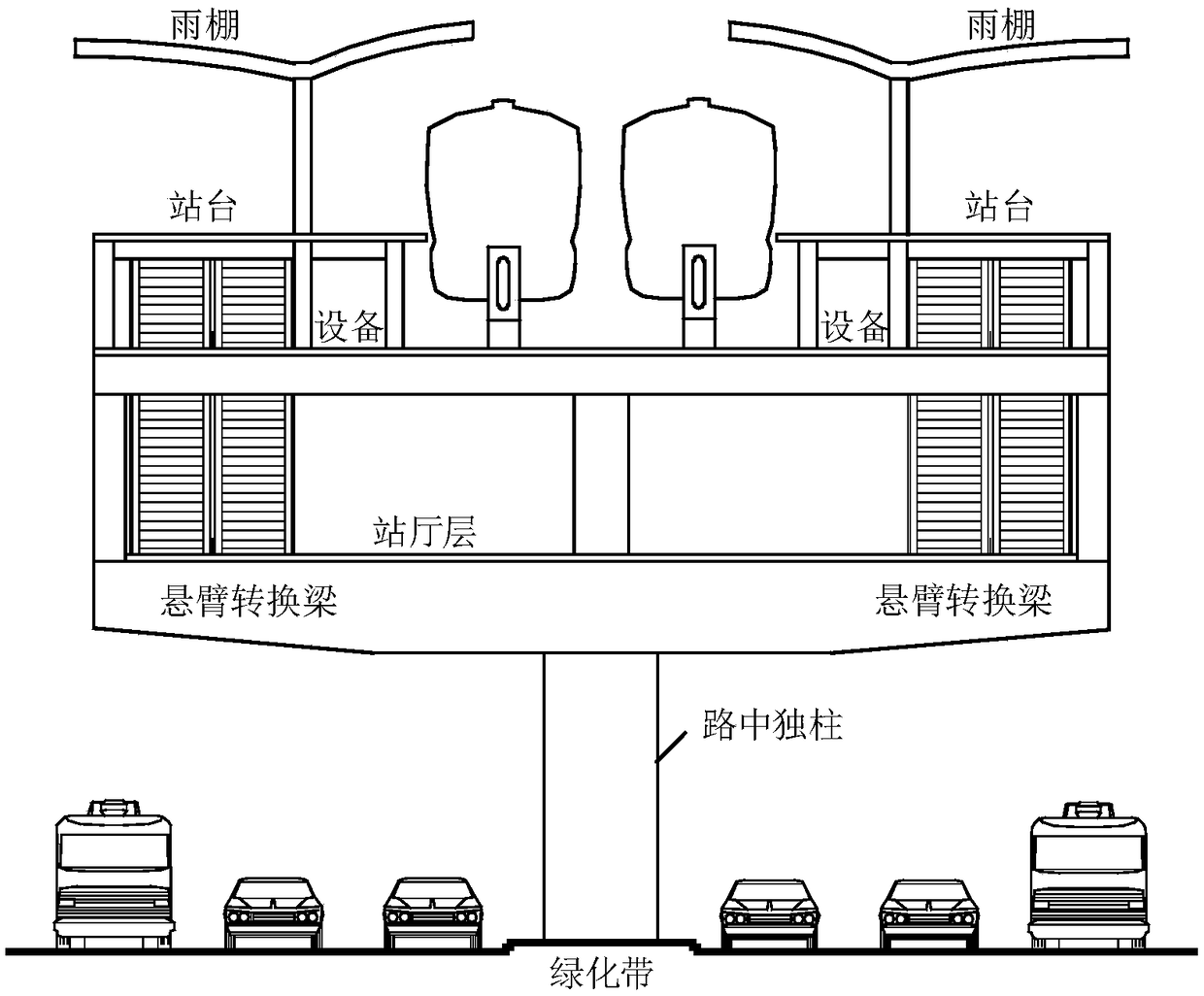

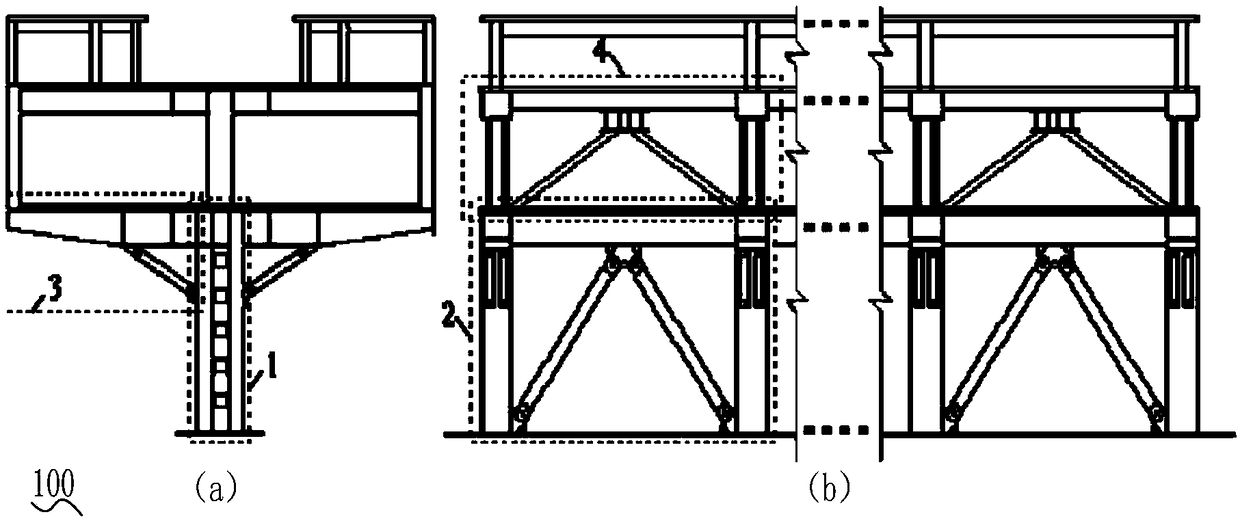

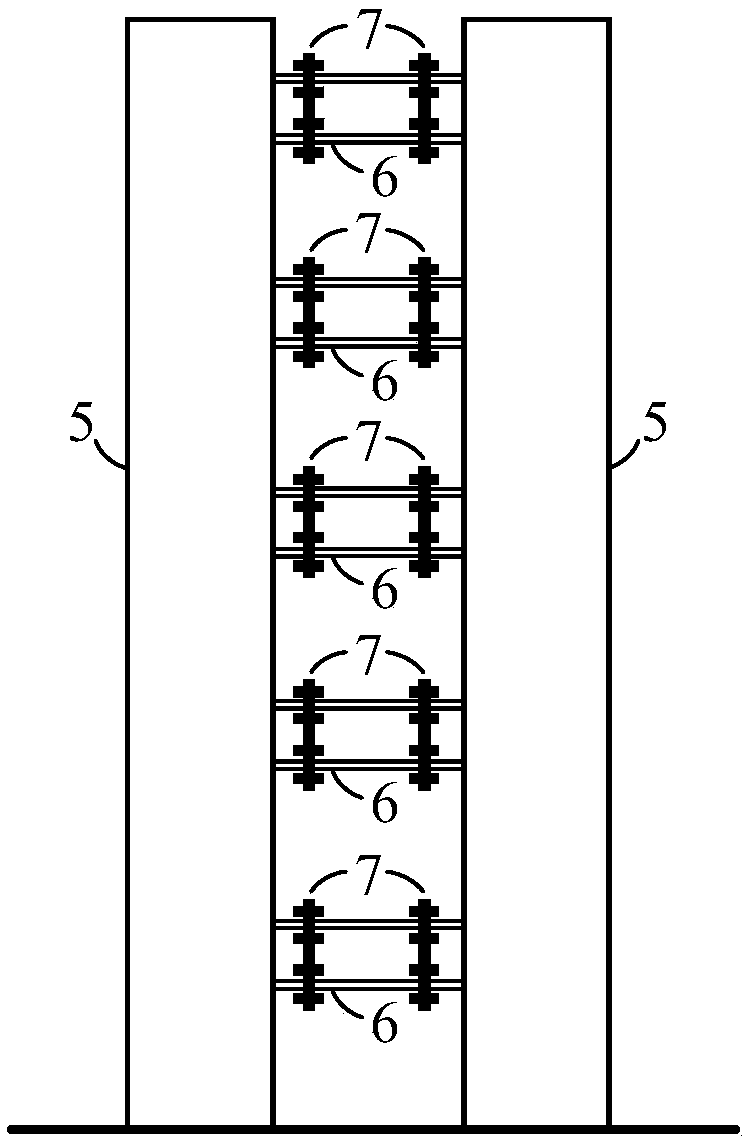

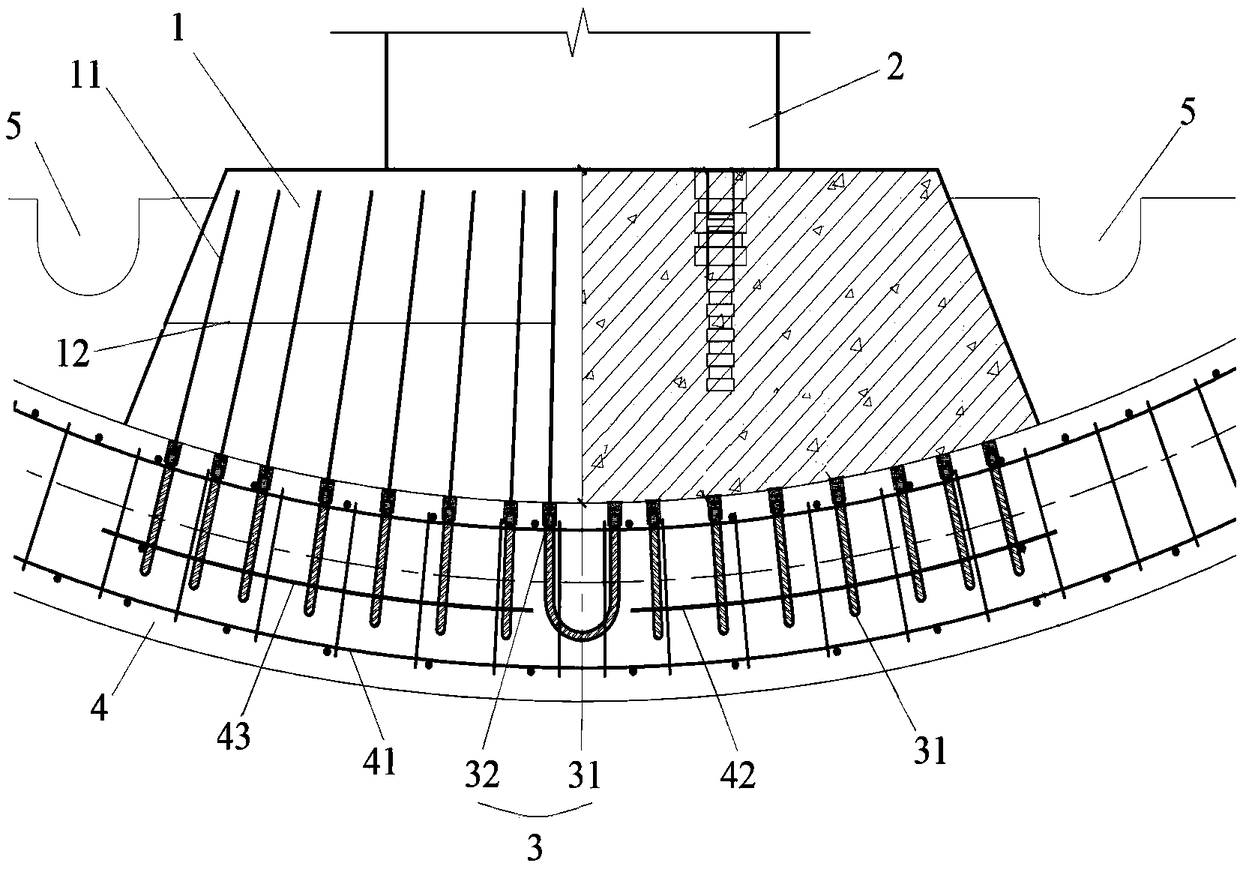

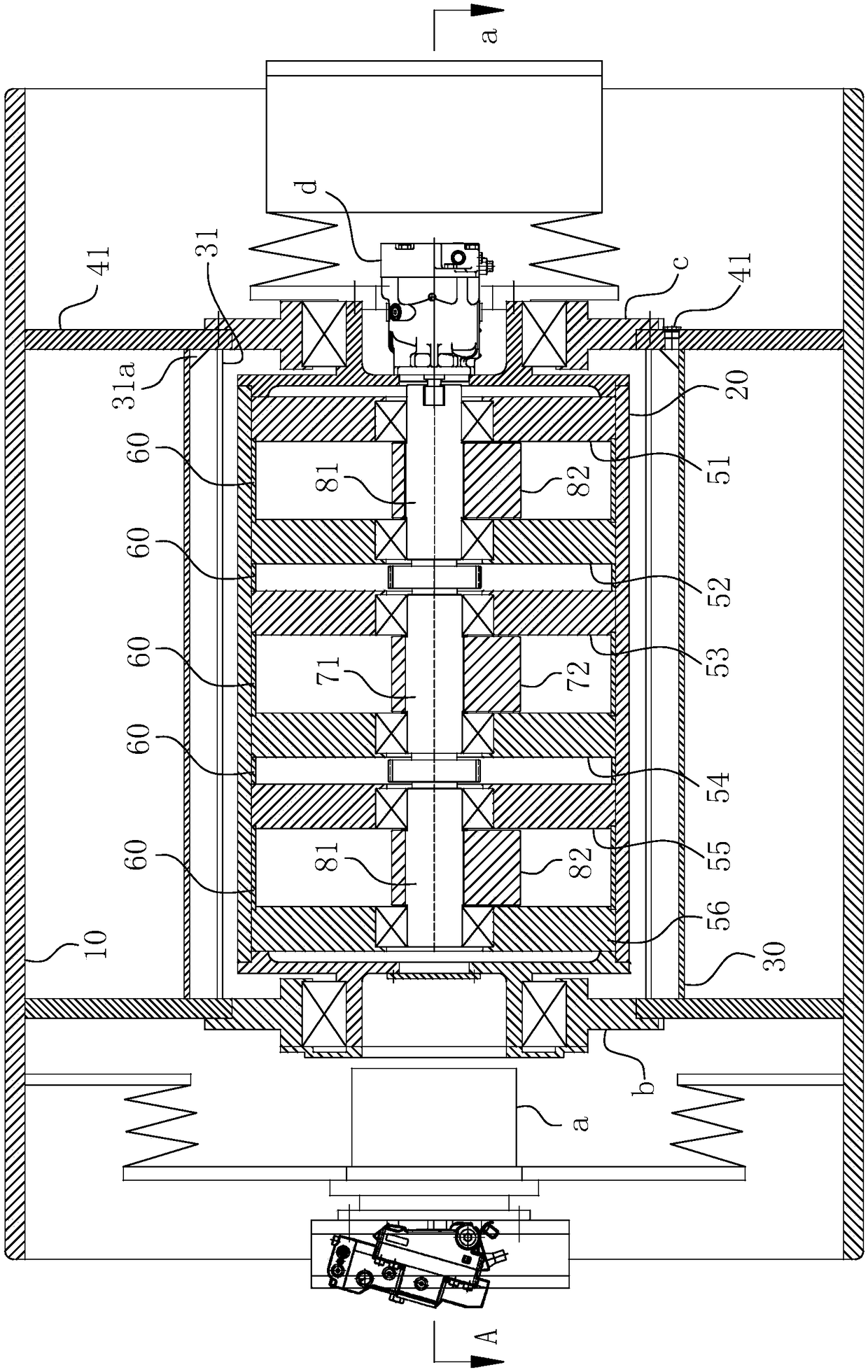

Energy dissipation body structure of elevated single-column station

PendingCN108952290AIncrease safety redundancyImprove torsion effectProtective buildings/sheltersExtraordinary structuresBraced frameEngineering

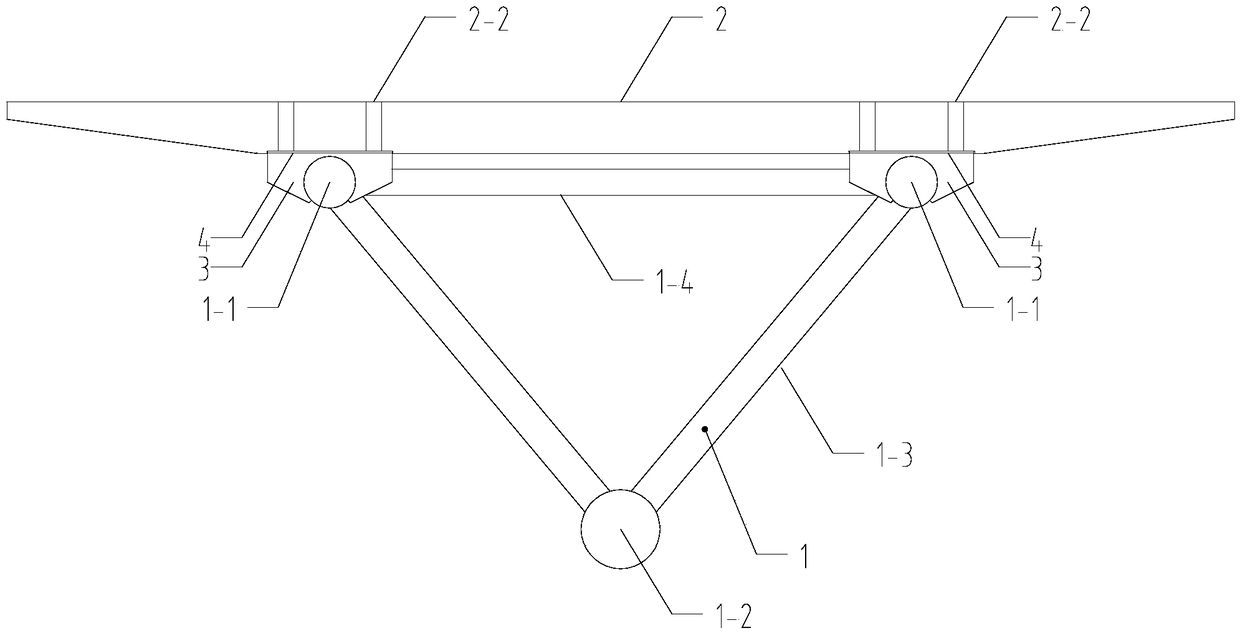

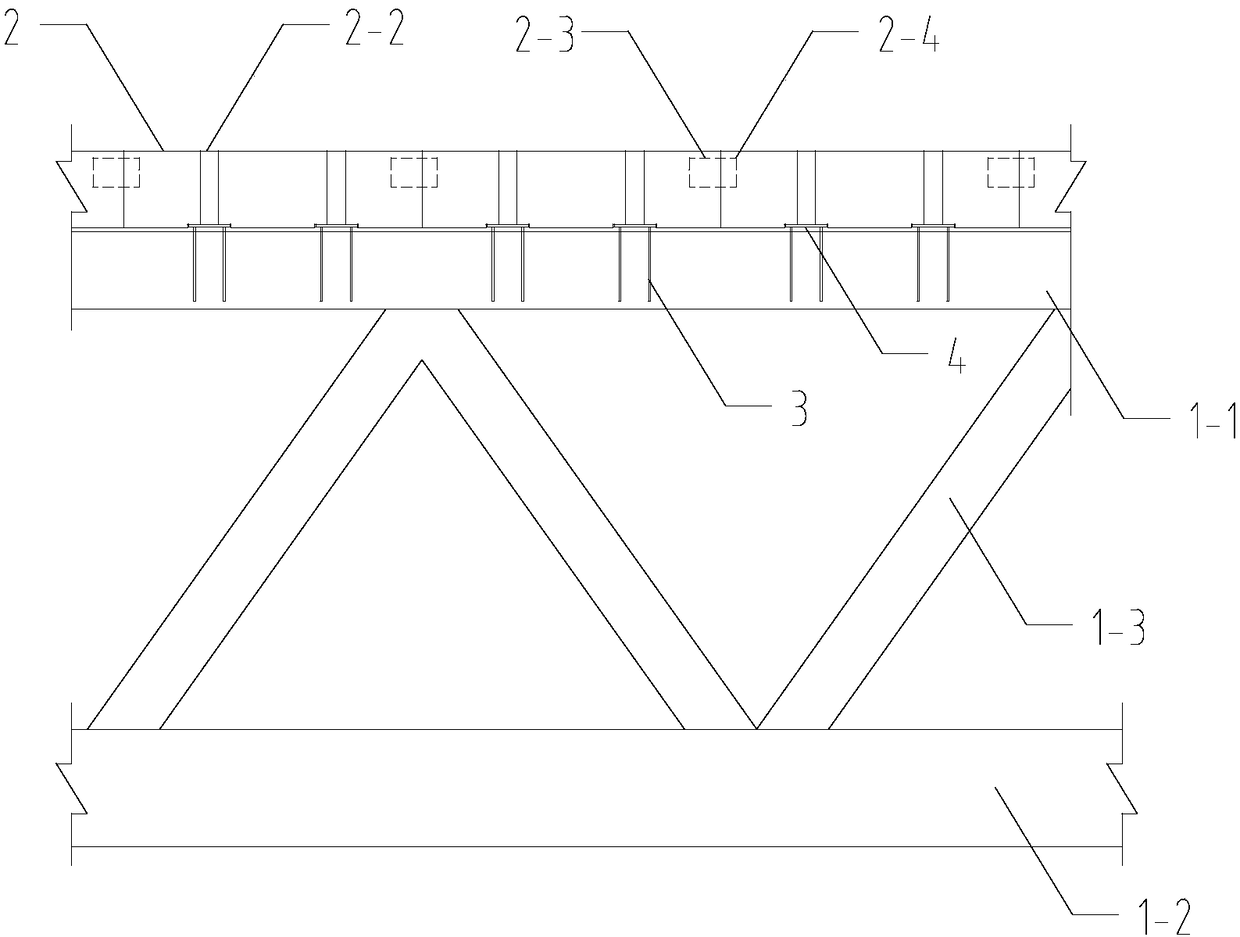

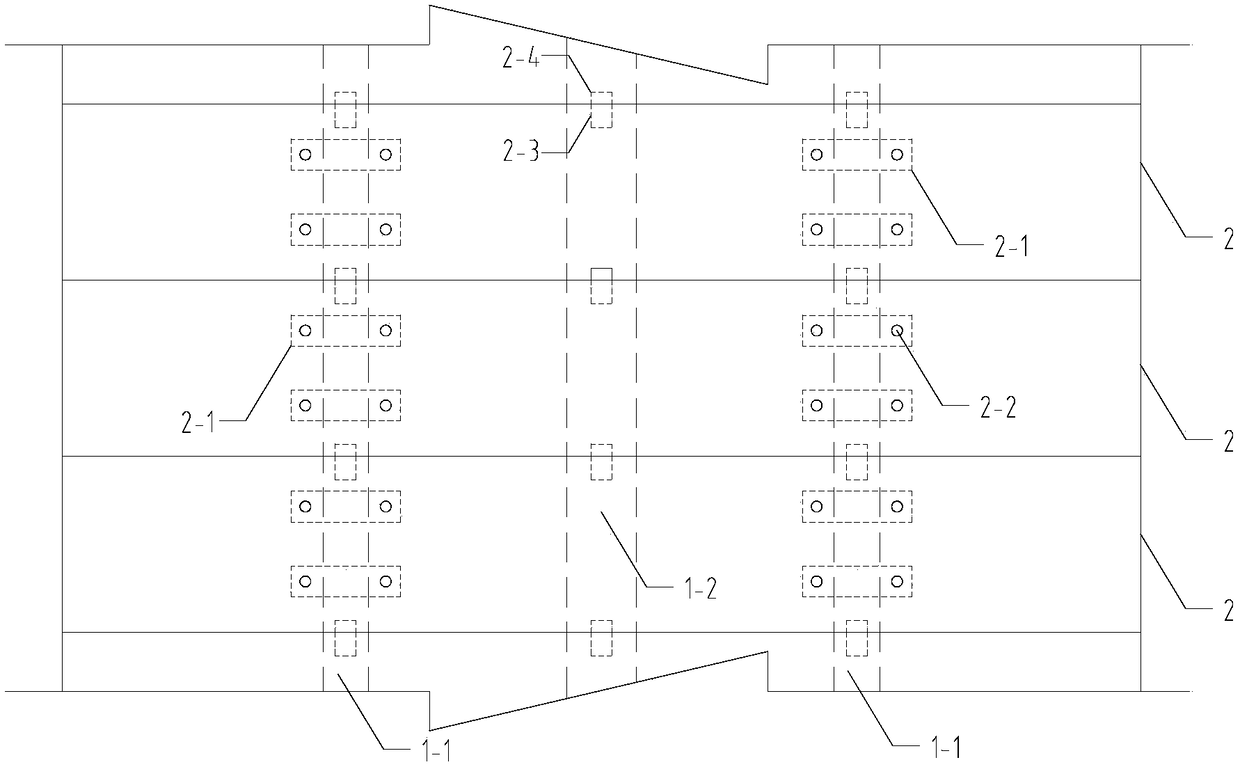

The invention discloses an energy dissipation body structure of an elevated single-column station. The energy dissipation body structure comprises energy dissipation pier studs, a bottom layer anti-buckling supporting frame, in-axillary additional anti-buckling supporting cantilever transfer girders and a two-layer shearing coupling beam eccentric supporting frame which are all used for providingadditional rigidity when the earthquake magnitude is smaller than or equal to the preset earthquake magnitude and enter a yield state from an elastic state to plastically deform so as to consume partof input energy of an earthquake independently or in freedom cooperation with one another when the earthquake magnitude is larger than the preset earthquake magnitude. The energy dissipation body structure is suitable for the elevated single-column station; for the same type of irregular structure, some energy dissipation sub-structure in the energy dissipation body structure can also be adopted in the similar anti-seismic weak link, and therefore the anti-seismic performance and after-disaster restorability of the energy dissipation body structure are improved, and the energy dissipation bodystructure has good popularization prospects.

Owner:TSINGHUA UNIV

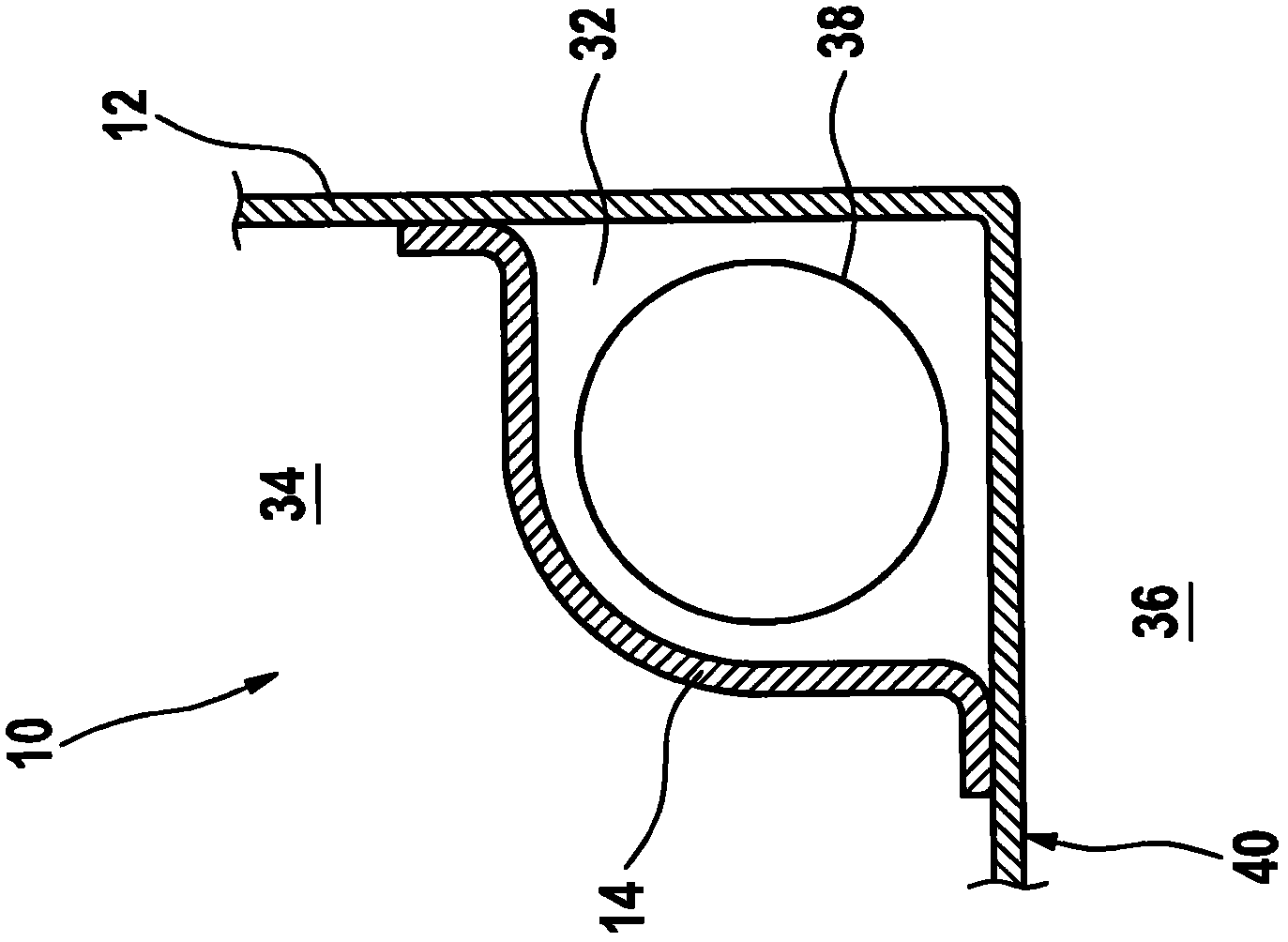

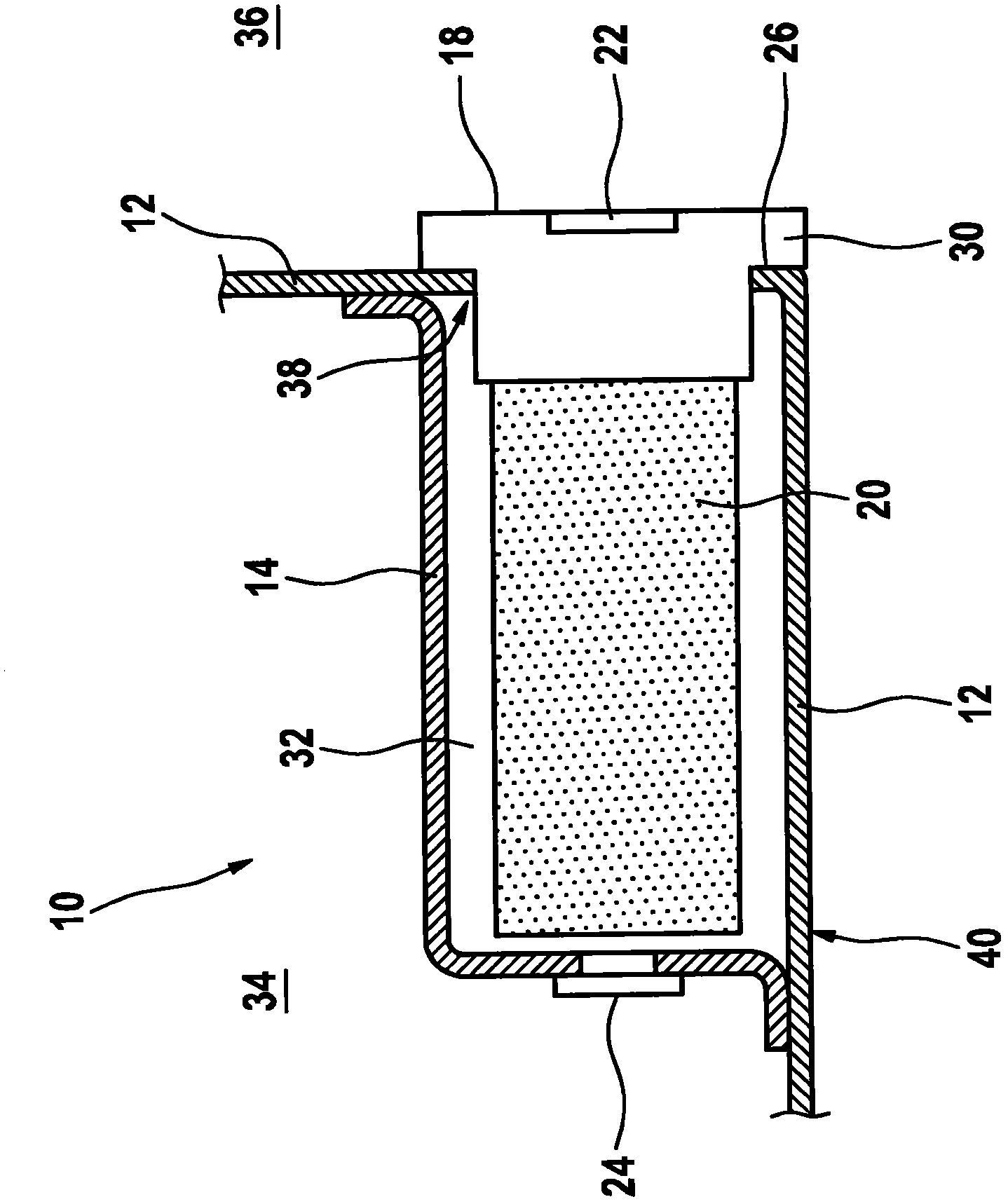

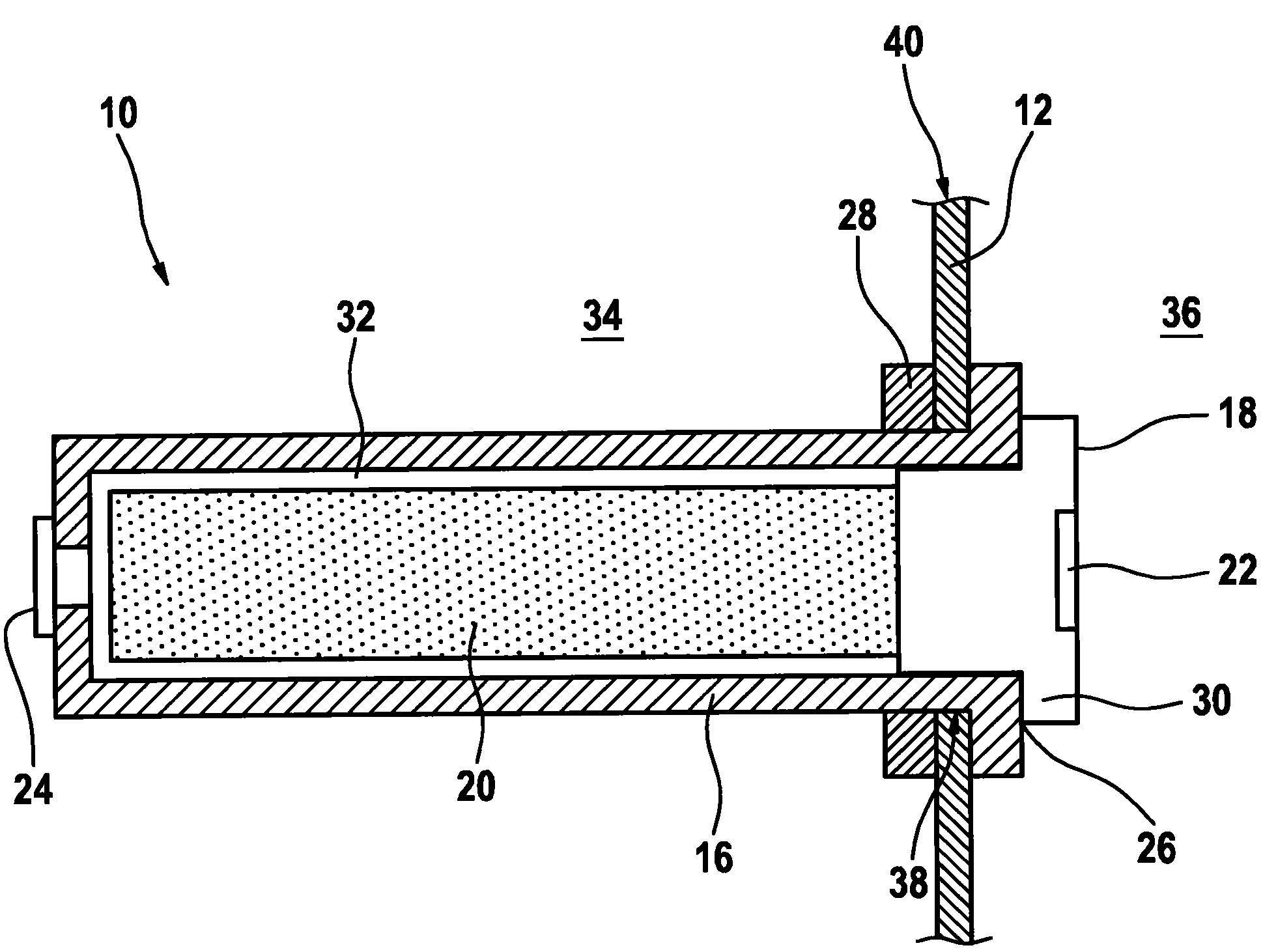

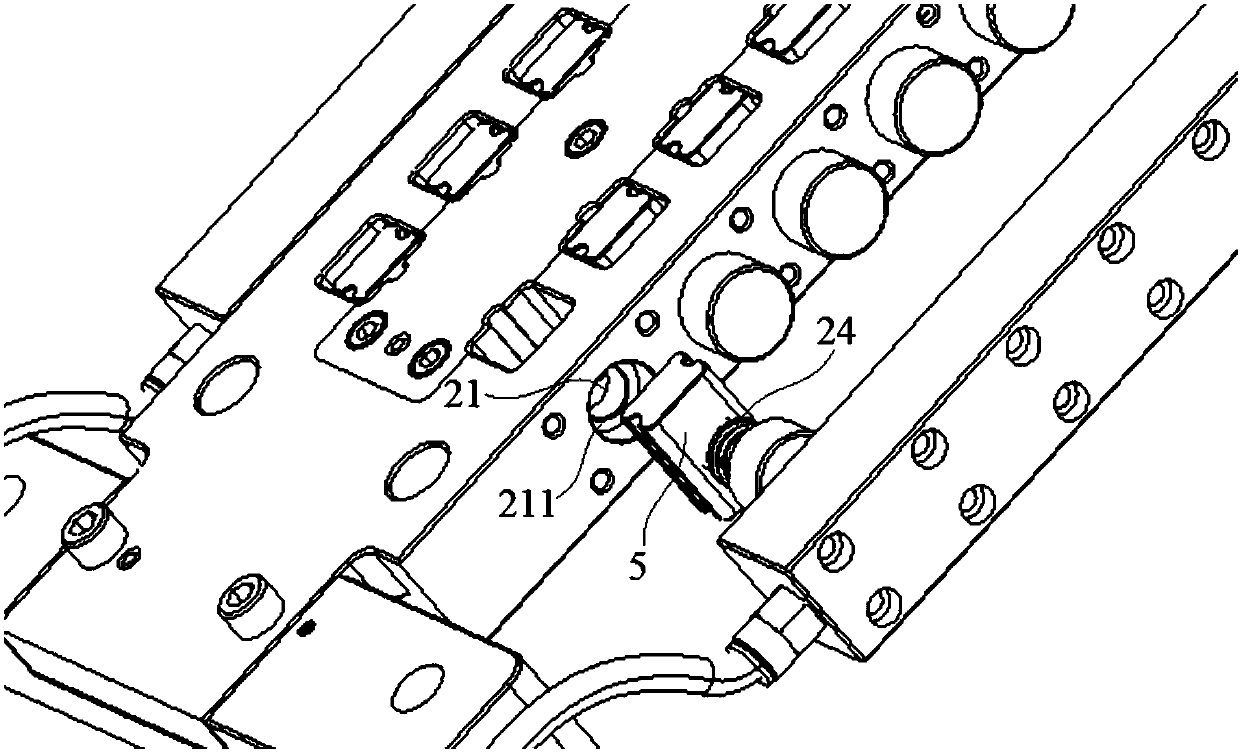

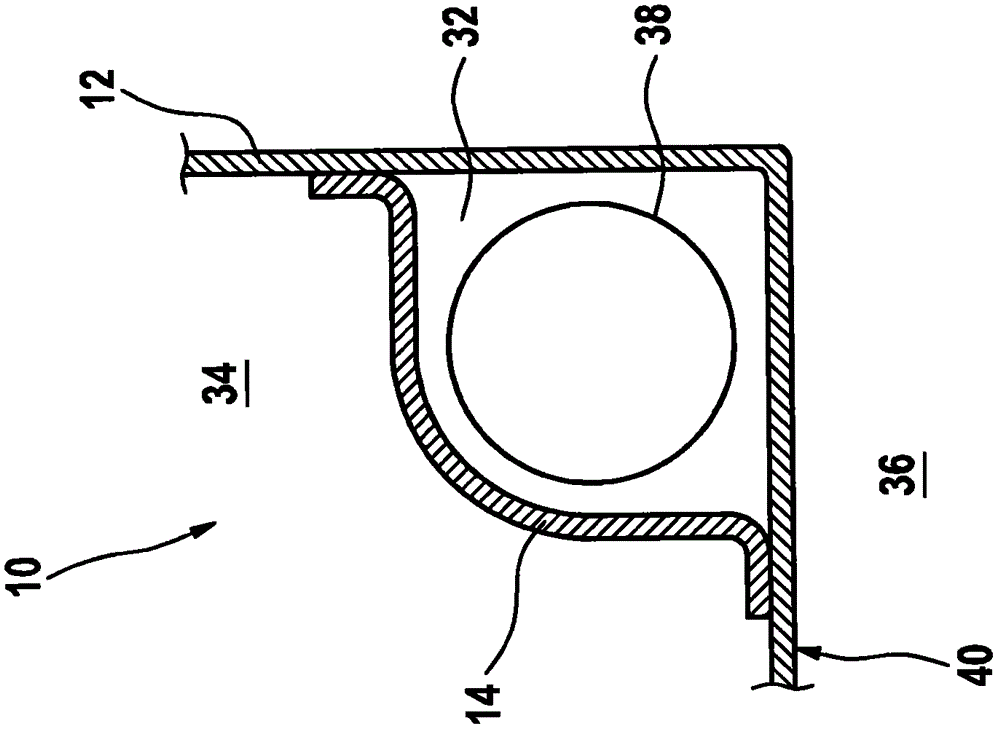

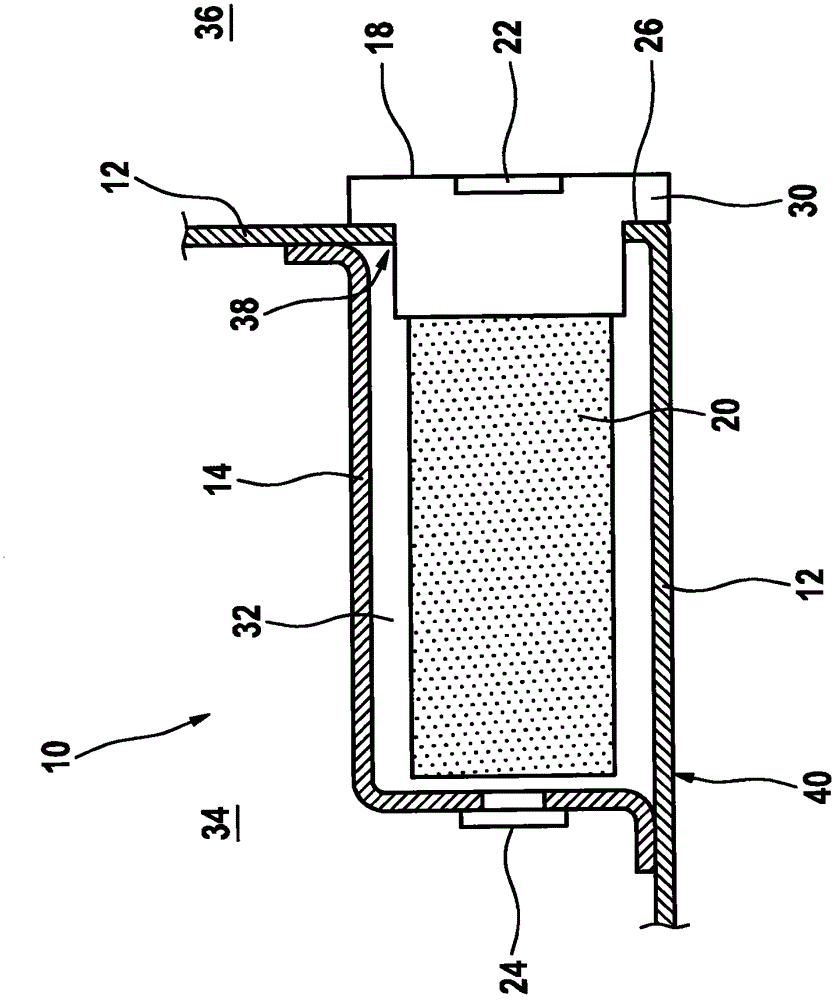

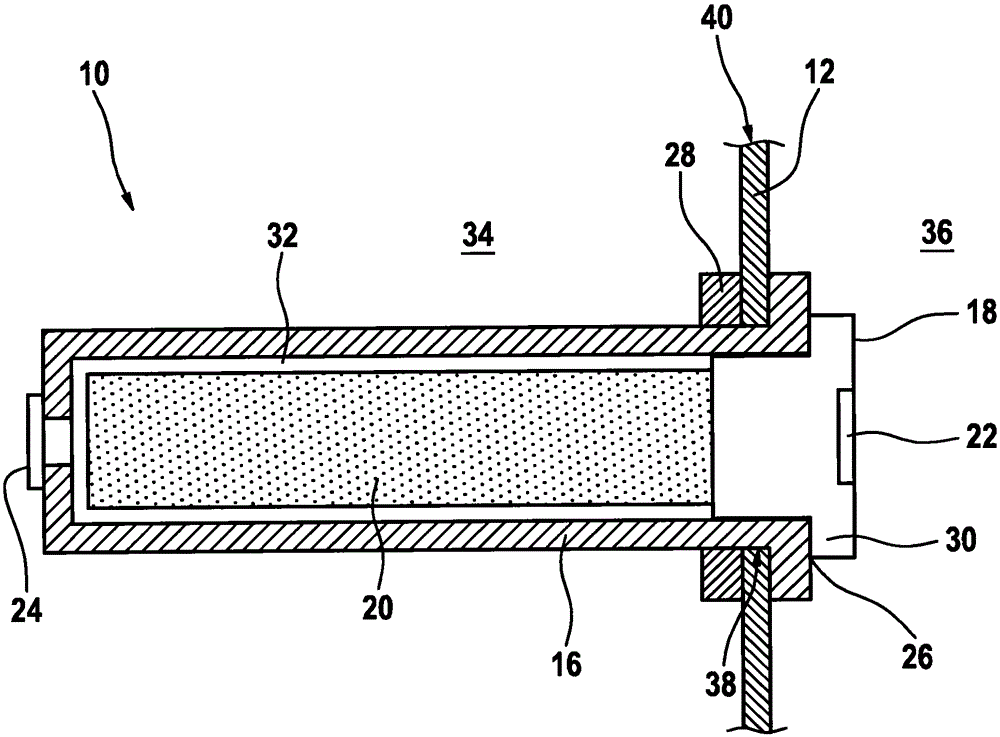

Drying device and battery system and motor vehicle having the drying device

ActiveCN103797608APrevent intrusionAvoid contactGas treatmentDispersed particle separationDesiccantEngineering

The invention relate to a drying device (10). In order to reduce a moisture content of a gas located in an inner chamber (34) of the housing (40), the drying device comprises a desiccant cartridge (18) having a desiccant (20). The drying device (10) comprises a protective chamber (32) which is or can be introduced into the housing (40). The protective chamber (32) is in a liquid-tight manner with respect to the inner chamber (34) and is connected to the internal space (34) in a gas-conducting manner. The desiccant cartridge (18) is arranged in the protective chamber. The invention further relates to a battery system (42) having the drying device (10) and relates to a motor vehicle having the battery system (42).

Owner:ROBERT BOSCH GMBH +1

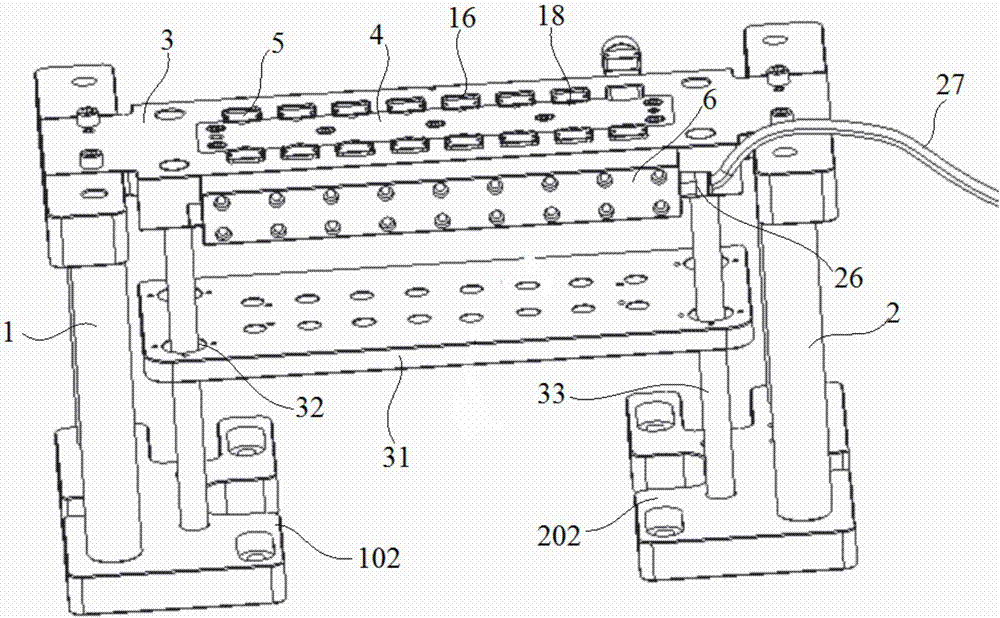

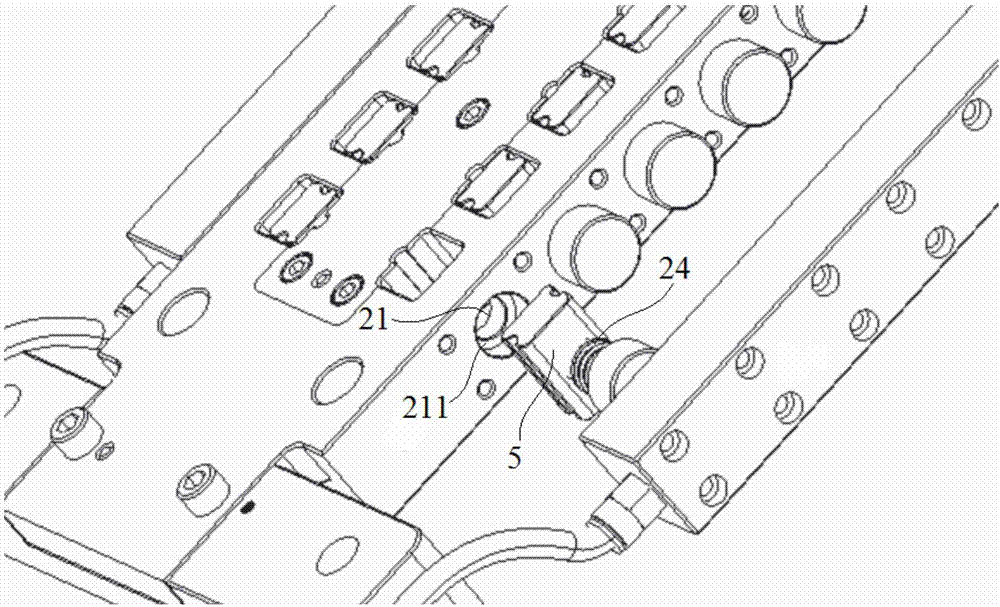

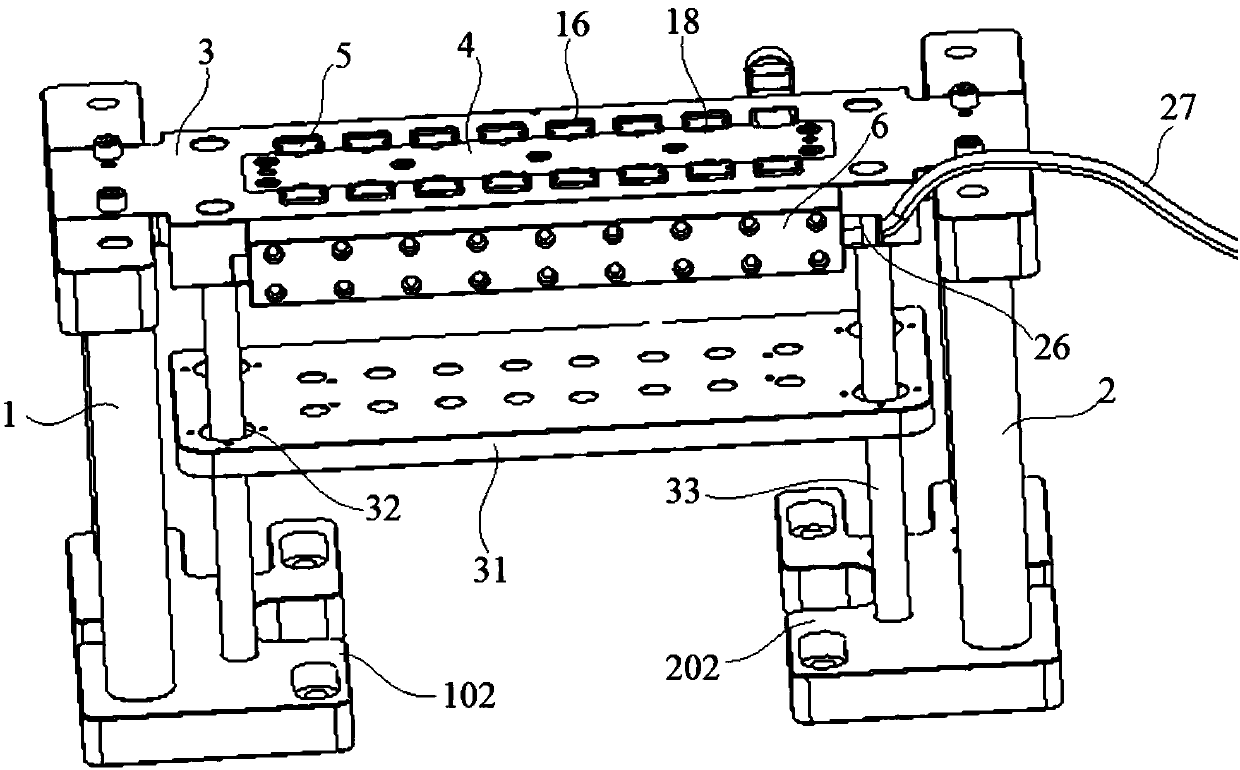

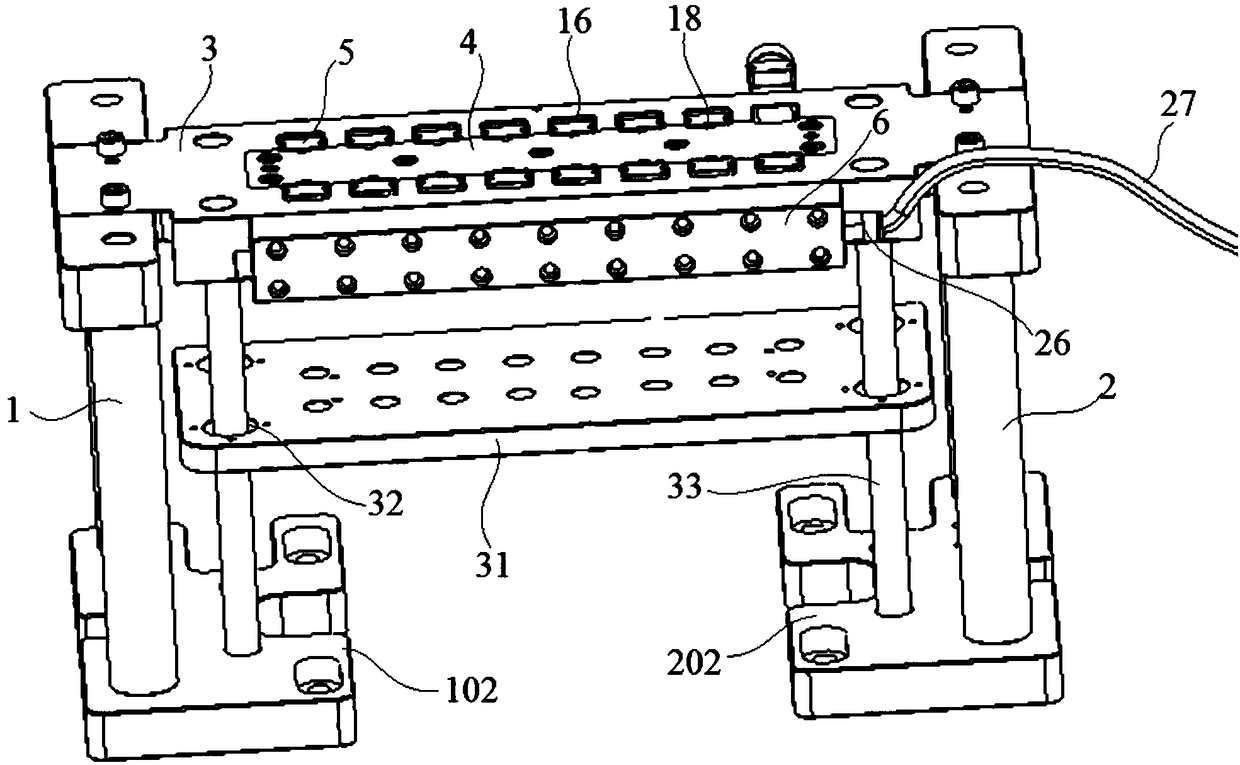

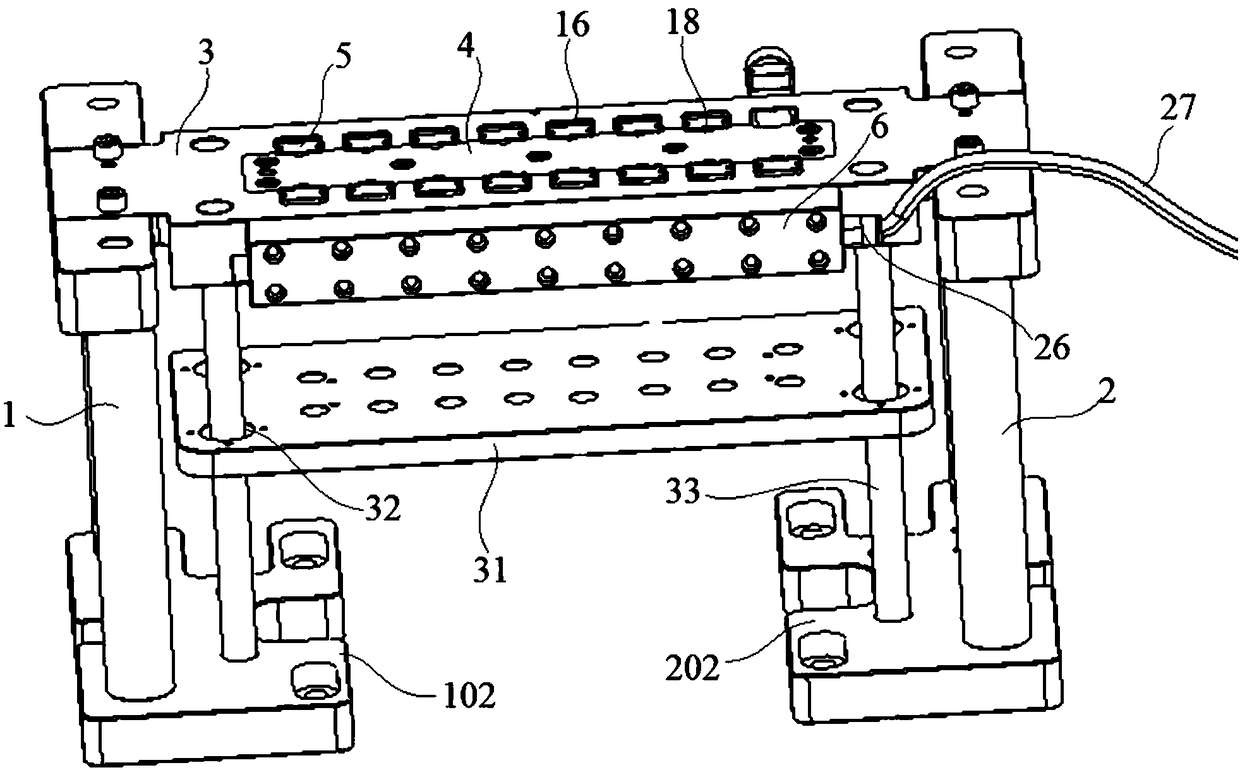

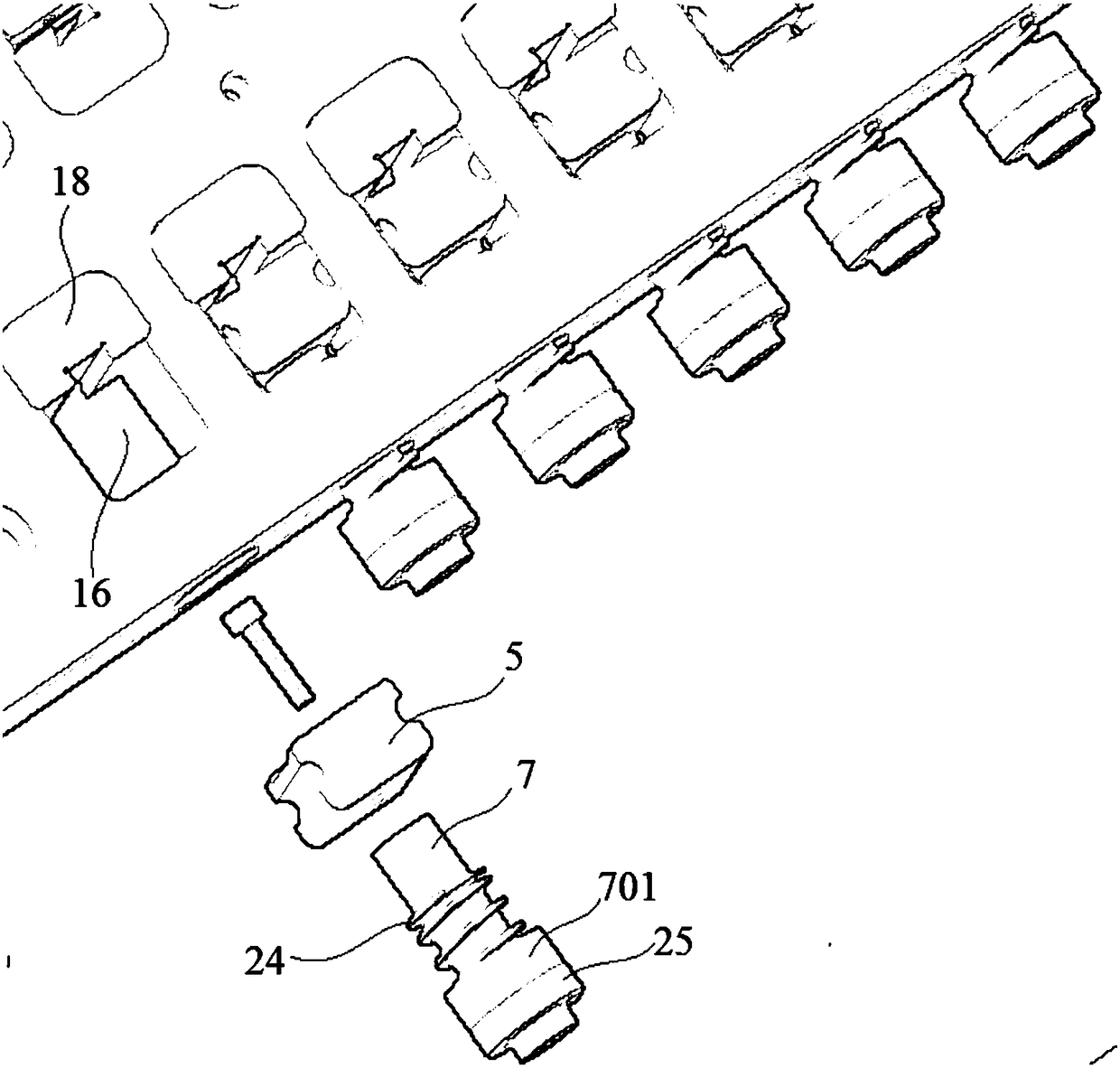

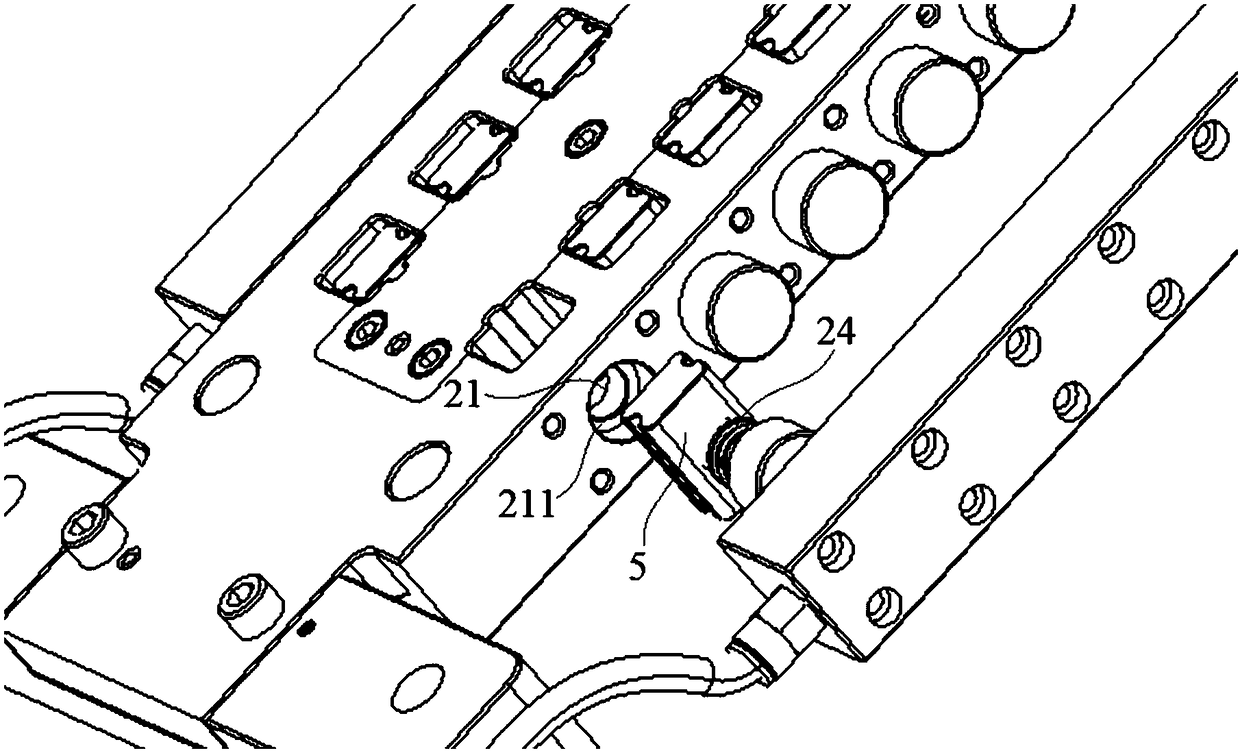

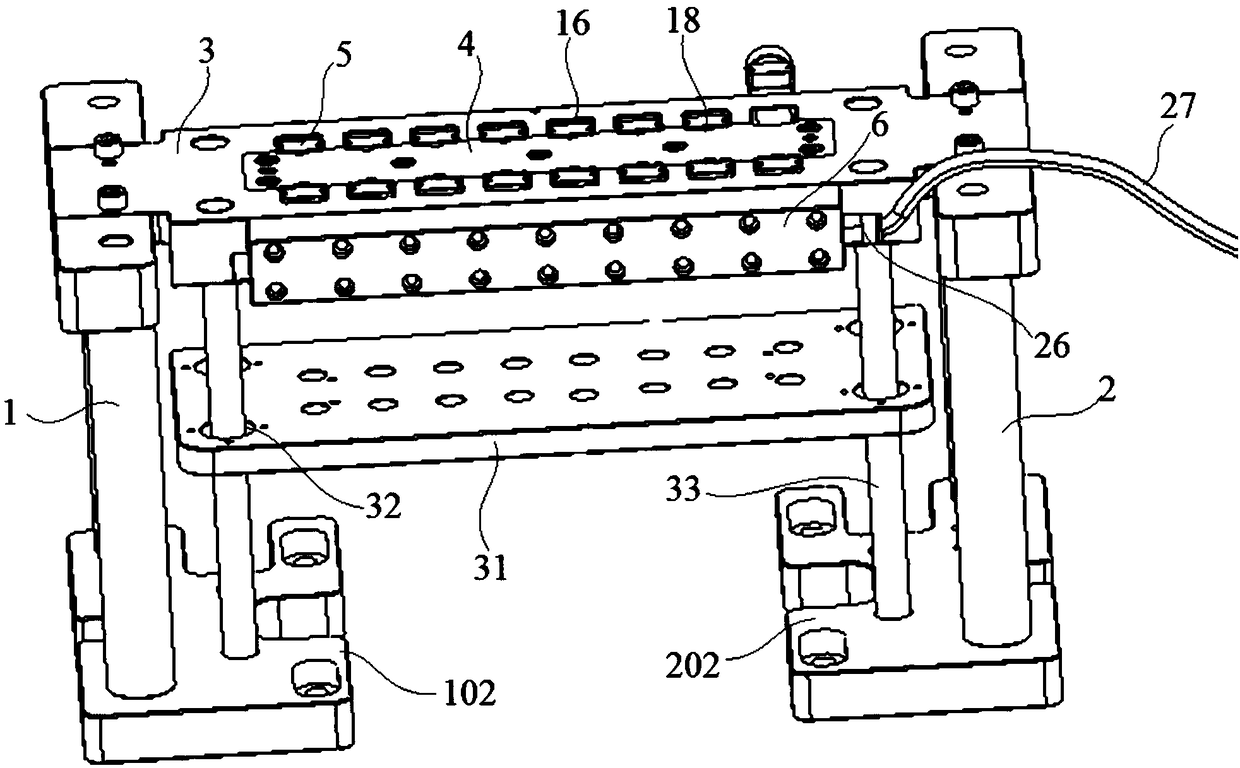

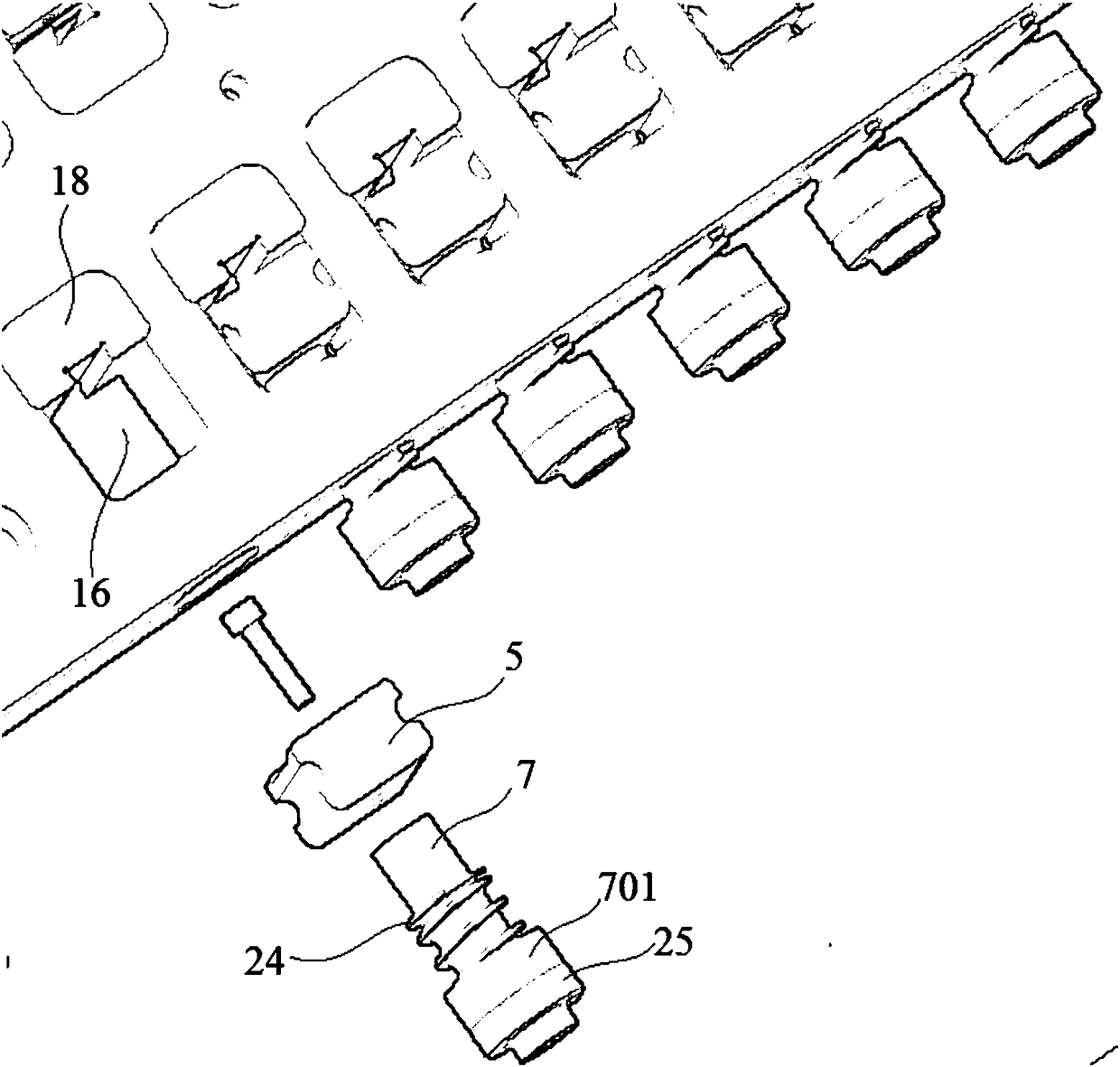

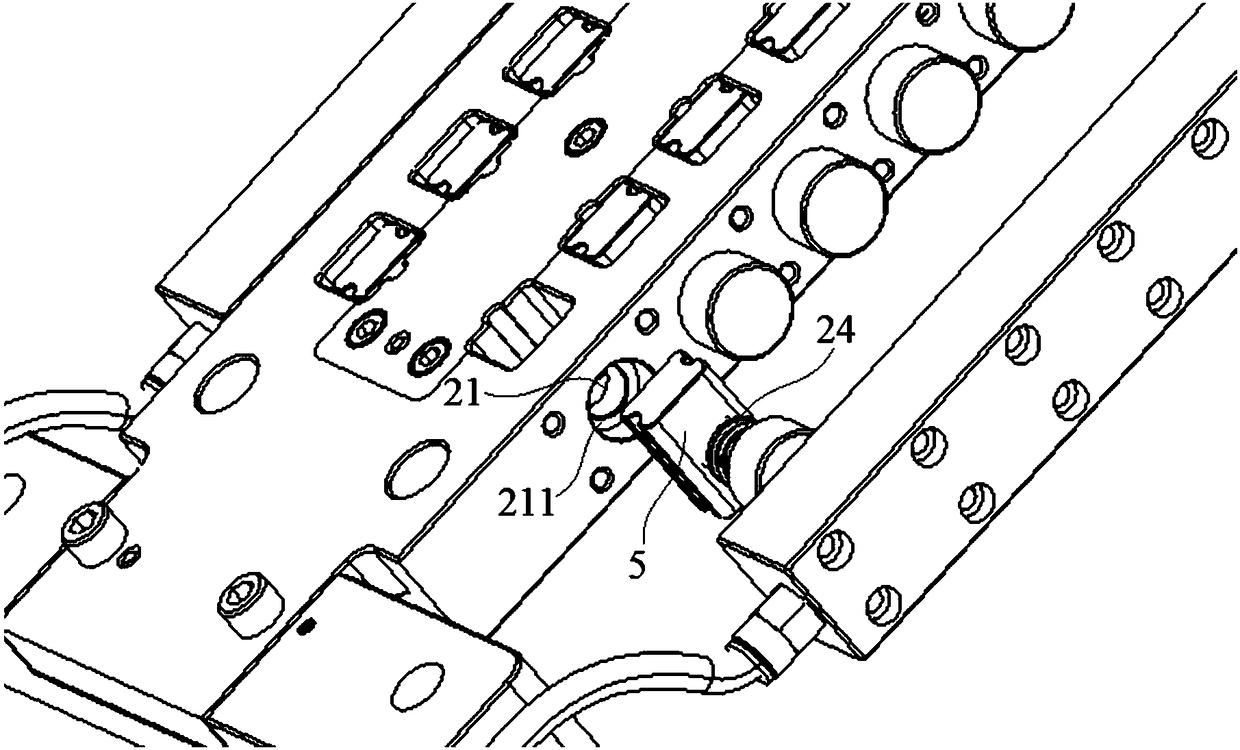

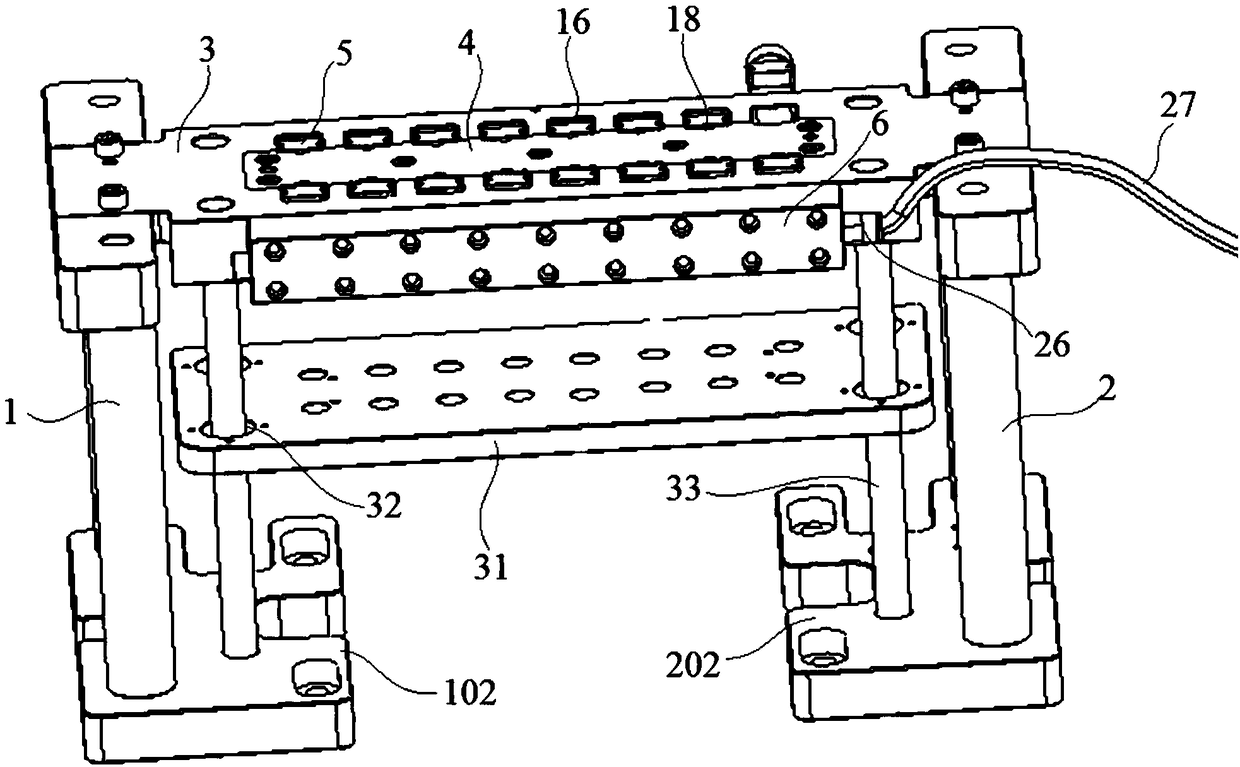

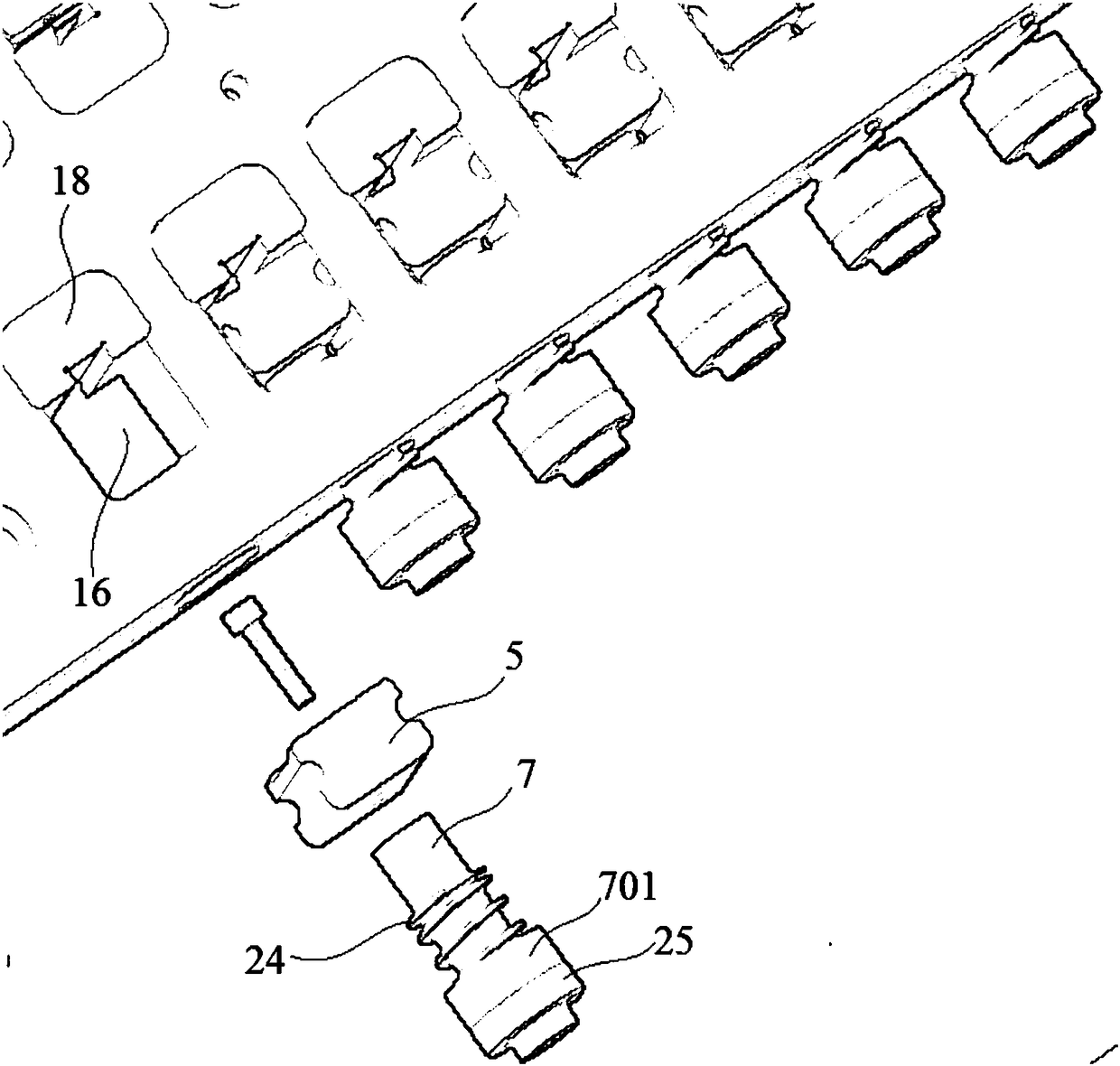

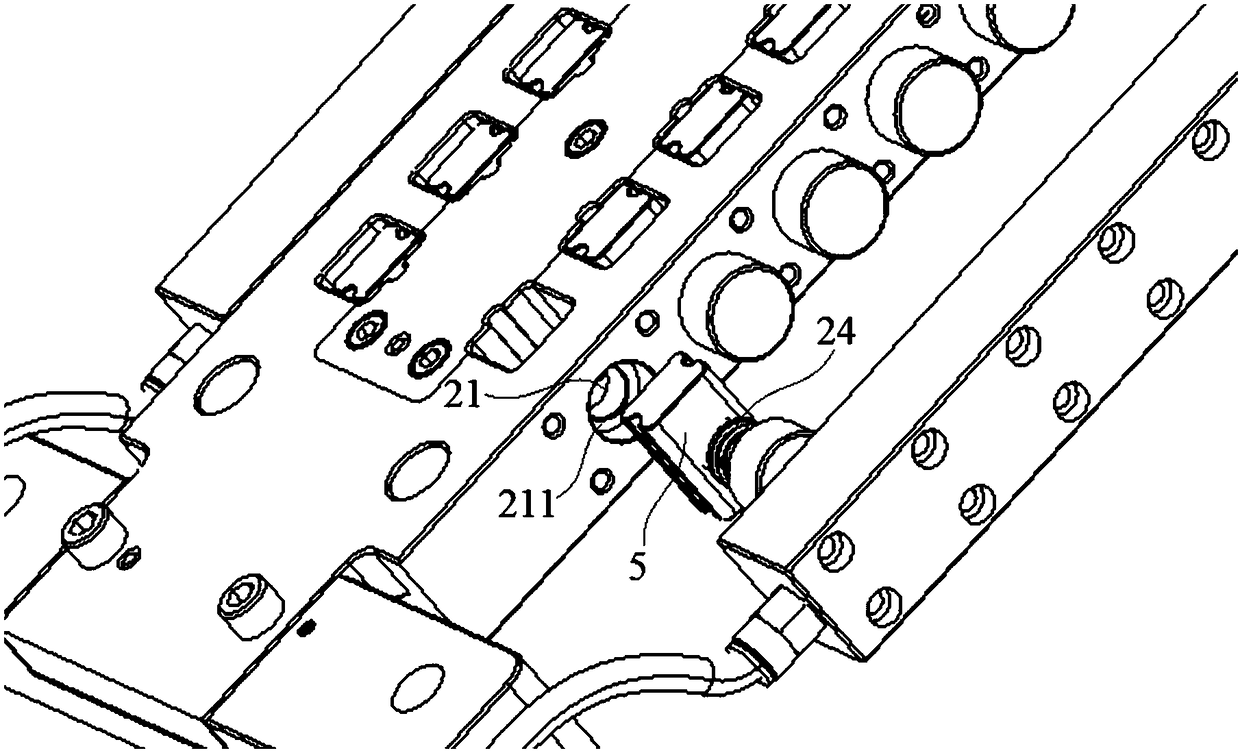

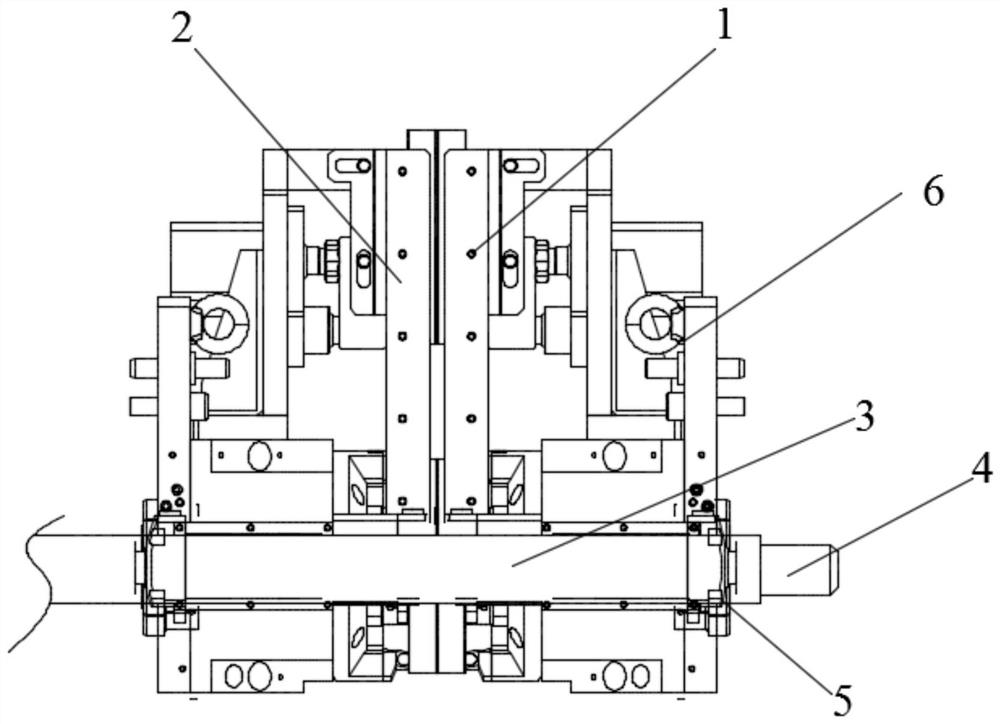

Hydraulic type clamp used for machining antenna brackets of tablet personal computer

InactiveCN107498348ALimited travelGuaranteed accuracyPositioning apparatusMetal-working holdersTablet computerPersonal computer

The invention discloses a hydraulic type clamp used for machining antenna brackets of a tablet personal computer. The hydraulic type clamp comprises a left supporting seat, a right supporting seat, a fixing plate, a locating plate, a clamping head and a pressure mechanism; the two ends of the fixing plate are fixedly connected with the left supporting seat and the right supporting seat correspondingly; the locating plate is fixedly connected with the fixing plate; a hydraulic oil hole is formed in one side surface of the pressure mechanism; one face, provided with clamping teeth, of a rack faces an arc-shaped clamping claw, the arc-shaped clamping claw is installed on the lower surface of a movable plate, and the front end of the arc-shaped clamping claw is embedded in the clamping teeth of the rack; a vertical clamping groove is formed in the inner side surface of a sliding block, and the sliding block is connected with a guiding strip through the vertical clamping groove in a clamping mode and is fixedly connected with the rack; and the lower end of a limiting screw rod penetrates through a pushing block from top to bottom and then is embedded in a center through hole of a pushing rod of a top plate air cylinder, and the limiting screw rod is sleeved with a limiting nut. According to the hydraulic type clamp used for machining the antenna brackets of the tablet personal computer, the stroke of the top plate air cylinder can be limited by arranging a limiting stud and the limiting nut, so that the rising stoke of the movable plate is in accordance with need, each rising stroke of the movable plate is fixedly consistent, and the machining precision is ensured.

Owner:KESEN SCI & TECH DONGTAI CO LTD

All-directional conductive polyurethane foam and preparation method thereof

ActiveCN111805920AIncrease elasticityGood flexibilityVacuum evaporation coatingSputtering coatingFiberPolymer science

The invention discloses all-directional conductive polyurethane foam and a preparation method thereof. The method comprises the following specific steps that S1, foam is prepared, wherein a foamed sponge taking polyurethane as the main component is cut into sheets; S2, conductive cloth is prepared, wherein polyurethane fiber plaid cloth is put into a vacuum chamber, and the plaid cloth is subjected to copper plating through multi-arc ion plating to form a conductive cloth; S3, the foam is cleaned; and S4, glue spraying and cloth pasting are carried out on the foam, wherein the cut foam is subjected to liquid glue spraying and conductive cloth pasting through a glue spraying and cloth pasting device. The polyurethane foam has the advantages of high conductivity, high softness, large extrusion degree, good shielding effect and the like, and has extremely high cost performance; and a cloth winding mechanism of the glue spraying and cloth pasting device can be disassembled, the replaceableproperty of the conductive cloth is ensured, and the all-directional conductive polyurethane foam with different sizes can be produced in large batches. The device has the advantages of being convenient to operate, firm in conductive cloth pasting, time-saving, labor-saving and the like.

Owner:SUZHOU AOYU RUBBER & PLASTIC TECH CO LTD

Hydraulic type processing clamp for smart phone antenna module

InactiveCN107617910AAchieve clamping and fixingAchieve elastic compressionPositioning apparatusMetal-working holdersEngineeringPiston rod

The invention discloses a hydraulic type processing clamp for a smart phone antenna module. The hydraulic type processing clamp for the smart phone antenna module comprises a left support, a right support, a fixing plate, a locating plate, chucks and pressure mechanisms. The two ends of the fixing plate are fixedly connected with the left support and the right support correspondingly. The locatingplate is fixedly connected with the fixing plate. A hydraulic oil hole communicates with T-shaped blind holes. A guide strip is vertically arranged, and the two ends of the guide strip are fixed to the outer side faces of a left installation beam and a left base plate. A rack is vertically arranged and is in contact connection with the inner surface of the guide strip. A sliding block is connected with the guide strip in a clamped manner through a vertical clamping groove and is fixedly connected with the rack. A plate jacking air cylinder is installed on the upper surface of the left base plate, and the upper surface of a push rod of the plate jacking air cylinder is fixedly connected with the lower surface of one end of a push block. The other end of the push block is fixedly connectedwith the sliding block. According to the hydraulic type machining clamp for the smart phone antenna module, force acts on the piston rod in a hydraulic manner, and through the chucks and locating convex blocks at the tail end of the piston rod, materials to be machined are clamped and fixed; and compared with a pneumatic manner and an electric manner, the hydraulic manner can provide a larger pressure, and the pressure is stable and uniform.

Owner:KESEN SCI & TECH DONGTAI CO LTD

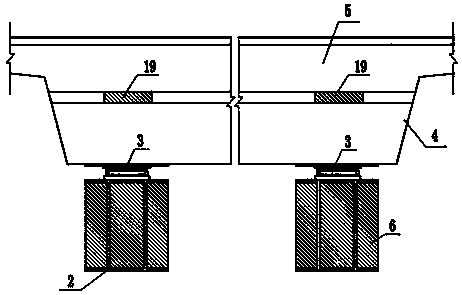

Connection structure and method of track beam and shield segment

The invention relates to the field of monorail traffic engineering, and discloses a connection structure and method of a track beam and a shield segment. The connection structure comprises a pedestalarranged at the bottom of the track beam, two supports arranged on the pedestal separately, and a plurality of embedded members embedded in the shield segment; the two ends of the track beam are detachably connected with the two supports respectively; a plurality of pedestal main ribs are arranged in the pedestal, each pedestal main rib is provided with an extension part which extends out of the end, in butt joint with the shield segment, of the pedestal, and each extension part corresponds to one embedded member and is in threaded fit insertion connection with the corresponding embedded member. By means of the connection structure and method of the track beam and the shield segment, connection of the track beam and the shield segment can be realized, the requirements for strength, rigidity and stability under load transfer of a vehicle and the track beam are met, linear adjustment, maintenance and replacement of the track beam are facilitated, construction is convenient, and the construction cost is low.

Owner:CHINA RAILWAY SIYUAN GRP SOUTHWEST SURVEY & DESIGN CO LTD +1

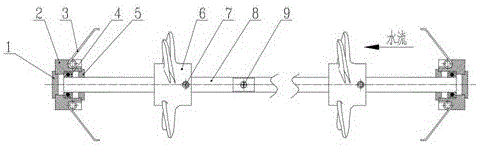

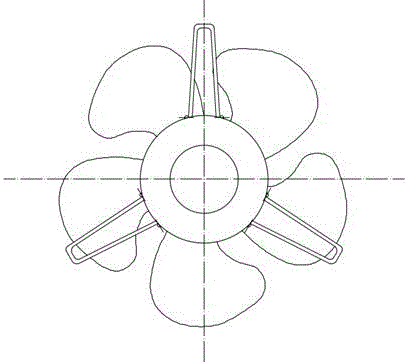

Condenser cleaning device based on impeller turbulent flow effect

PendingCN106595383AAvoid damageEasy to installHeat transfer modificationFlush cleaningImpellerEngineering

The invention discloses a condenser cleaning device based on an impeller turbulent flow effect. The device consists of torsion spring tripods at two ends for fixing with the inner wall of a heat exchange pipe, and an impeller set in middle for reinforcing turbulent flow. The torsion spring tripods consist of cylinder bases and torsion springs; the torsion springs are mounted on outer bosses of the cylinder bases to form triangular structures with the same included angles; and impellers are mounted in inner bosses of the cylinder bases through shafts and bearings. The middle impeller set is formed by serially connecting multiple impellers by a shaft; and the shaft and the impellers are connected by fastening screws. The shaft consists of two sections; and the two sections of shaft are fixedly connected through a connecting shaft bolt. The shaft and the torsion spring tripods at two ends are connected by bearings. The device can realize online cleaning of a condenser, and is simple in structure, low in cost, high in stability, convenient to install and suitable for other tubular heat exchange equipment.

Owner:SHANGHAI SUS ENVIRONMENT

Replacement structure of existing bracket of cantilever beam bridge and construction method

PendingCN111593650AEliminate potential safety hazardsEliminate fatigue damageBridge structural detailsBridge erection/assemblyCantilevered beamArchitectural engineering

The invention provides a replacement structure of the existing bracket of a cantilever beam bridge and a construction method. The problem of further development of bracket crack diseases can be fundamentally solved, the cost can be saved, and popularization and implementation are facilitated. The replacement structure of the existing bracket of the cantilever beam bridge comprises an upper bracketend with the cantilever beam bridge and a lower bracket end with the cantilever beam bridge, a steel box beam bracket is installed at the lower bracket end through a high-strength pull rod anchoringsystem and anchoring bolts, a support body is installed on the steel box beam bracket, and the support body makes contact with the beam bottom of the upper bracket end and the beam bottom of the lowerbracket end.

Owner:SHANDONG LUQIAO GROUP +1

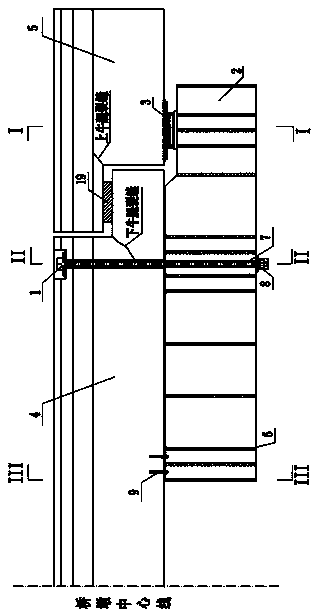

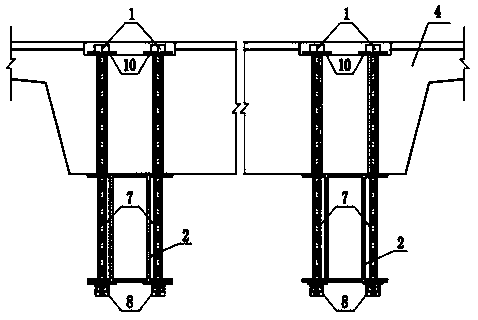

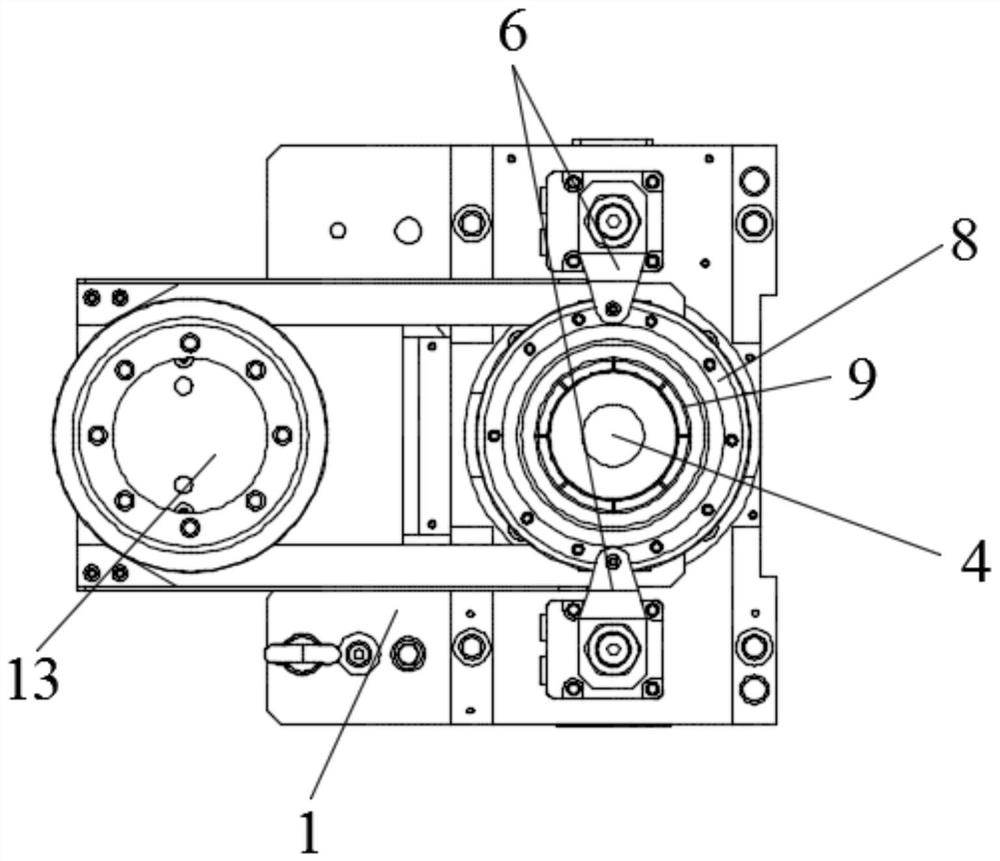

Rail vehicle and traction motor thereof

ActiveCN109519479AFully Extruded Replacement ImplementationAchieve replacementShaftsBearing componentsTraction motorOil storage

The invention discloses a traction motor. The traction motor comprises a bearing outer oil seal, a bearing and a bearing inner oil seal, wherein the bearing outer oil seal, the bearing and the bearinginner oil seal are sequentially arranged in the axial direction, an outer oil seal oil storage chamber is formed in the bearing outer oil seal, and an inner oil seal oil storage chamber is formed inthe bearing inner oil seal. The traction motor further comprises an annular grease pocket, wherein the annular grease pocket comprises an annular groove which is coaxially formed with the bearing anda control piece which is used for driving the annular groove to move to be in contact with the bearing in the axial direction or move to be away from the bearing in the axial direction; the annular groove is arranged in the outer oil seal oil storage chamber or the inner oil seal oil storage chamber; the end, close to the bearing, of the annular groove in the axial direction is open; the end, awayfrom the bearing, of the annular groove in the axial direction is sealed, and a grease supplement opening is formed in the side, close to the annular grease pocket, of the bearing. Old grease in thebearing of the traction motor can be completely replaced during grease supplement maintenance. The invention further discloses a rail vehicle comprising the traction motor, wherein the old lubricatinggrease in the bearing of the traction motor can be completely replaced during grease supplement maintenance.

Owner:CSR ZHUZHOU ELECTRIC LOCOMOTIVE RES INST

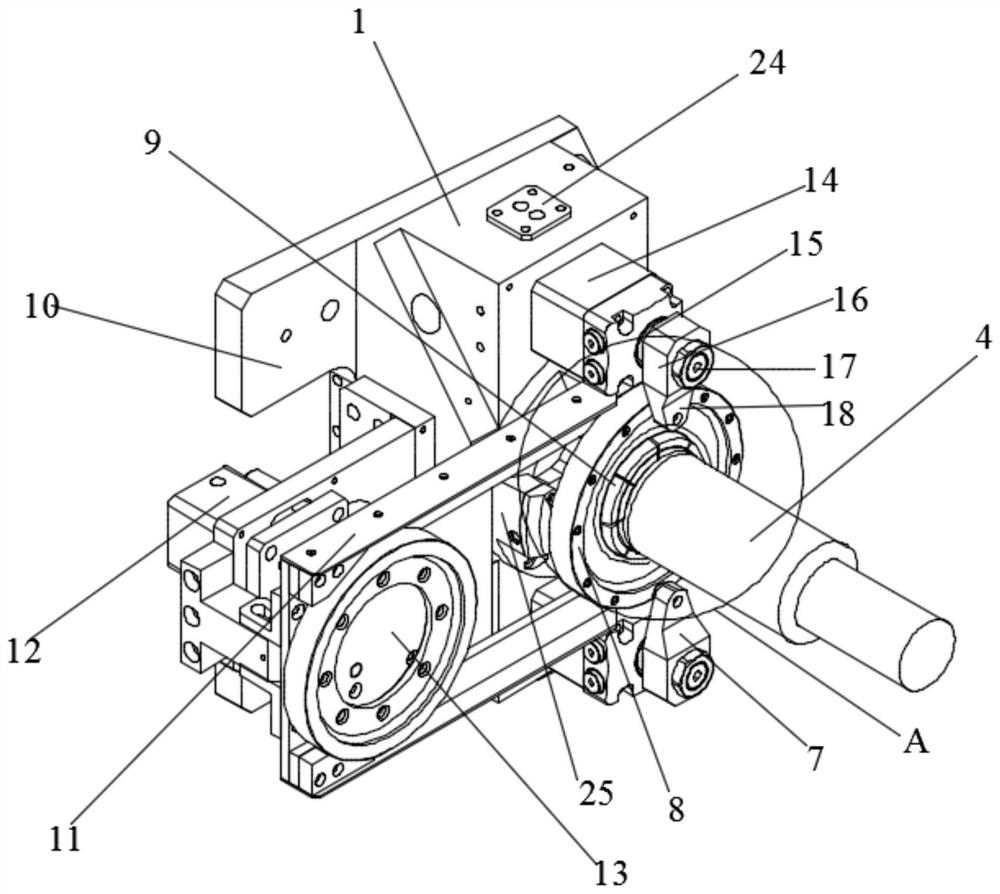

Coal mining machine traveling wheel bearing convenient to maintain

ActiveCN112412986AEasy maintenanceEasy to disassembleBearing unit rigid supportStructural engineeringProcess engineering

The invention discloses a coal mining machine traveling wheel bearing convenient to maintain. The inner ring of the coal mining machine traveling wheel bearing is connected with a traveling rotating shaft in an axial limiting and radial limiting mode, and the inner ring of the coal mining machine traveling wheel bearing and the traveling rotating shaft are arranged in a clamped mode, so that the bearing can be conveniently disassembled, and the maintenance and replacement capacity is improved. The invention further provides a convenient-to-disassemble mounting mechanism for the coal mining machine traveling wheel bearing convenient to maintain. The convenient-to-disassemble mounting mechanism can effectively guarantee the mounting convenience and the replacement performance of the bearing,meanwhile, even if a bearing seat is damaged, the bearing seat is convenient to replace, the modular performance is guaranteed, the maintenance performance of a coal mining machine is effectively improved, and the maintenance cost of the coal mining machine is reduced.

Owner:LULIANG UNIV

Clamping fixture for ultra-thin mobile phone vibration motor machining

InactiveCN109382684AReduce the use of laborIncrease productivityPositioning apparatusMetal-working holdersSelf lockingEngineering

The invention discloses a clamping fixture for ultra-thin mobile phone vibration motor machining. The clamping fixture comprises a left support, a right support, a fixed plate, a positioning plate, clamping heads and a pressure mechanism; the clamping heads are located on the side away from the center, stepped holes running through avoidance through holes are formed in the surfaces of the two sides of the fixed plate, hydraulic oil holes are communicated with T-shaped blind holes respectively, a movable plate is provided with at least two mounting through holes, at least two guide columns penetrate through the mounting through holes of the movable plate, the upper ends of the guide columns are connected with the fixed plate, the lower ends of the guide columns are connected with a left base plate of the left support and a right base plate of the right support respectively, self-locking cylinders are arranged on the side surface of the movable plate, the self-locking cylinders are fixedly installed on the outer side surfaces of connecting blocks, and piston rods of the self-locking cylinders penetrate through the connecting blocks, are located below the movable plate and are in contact connection with the outer side surfaces of the guide columns. Accordingly, by means of a spring on the piston rod, the pressure of the clamping head at the tail end of the piston rod has certain toughness, elastic compression on a to-be-machined material is achieved, the phenomenon that the to-be-machined material is pressed to be damaged is avoided, and the quality of products is guaranteed.

Owner:KUNSHAN KERSEN SCI & TECH

Hydraulic clamping fixture for intelligent displayer accessory machining

InactiveCN109382687ARealize automatic feedingPrevent fallingWork clamping meansPositioning apparatusEngineeringSelf locking

The invention discloses a hydraulic clamping fixture for intelligent displayer accessory machining. The hydraulic clamping fixture comprises a left support, a right support, a fixed plate, a positioning plate, a clamping head and a pressure mechanism; the two ends of the fixed plate are fixedly connected with the left support and the right support respectively, the positioning plate is fixedly connected with the fixed plate, the two side surfaces of the fixed plate are provided with stepped holes communicated with avoidance through holes, hydraulic oil holes are connected with oil pumps through hydraulic oil tubes, two guide pillars located on the same side in four guide pillars are anti-skid guide columns, a trapezoidal section is arranged on the side, close to the exterior, of each anti-skid guide column, the upper portions of connecting blocks are fixedly connected with the side surface of a movable plate, self-locking cylinders are fixedly installed on the outer side surfaces of the connecting blocks, and piston rods of the self-locking cylinders penetrate through the connecting blocks, are located on the lower portion of the movable plate and are in contact connection with theouter side surface of the guide columns. Accordingly, by means of the anti-skid guide columns and the trapezoidal sections, the lower portions of the anti-skid guide columns are thicker than the upper portions of the anti-skid guide columns, the movable plate can be clamped, gliding of the movable plate is prevented, the stability of a to-be-machined material in the machining process is guaranteed, and the machining precision is guaranteed.

Owner:KESEN SCI & TECH DONGTAI CO LTD

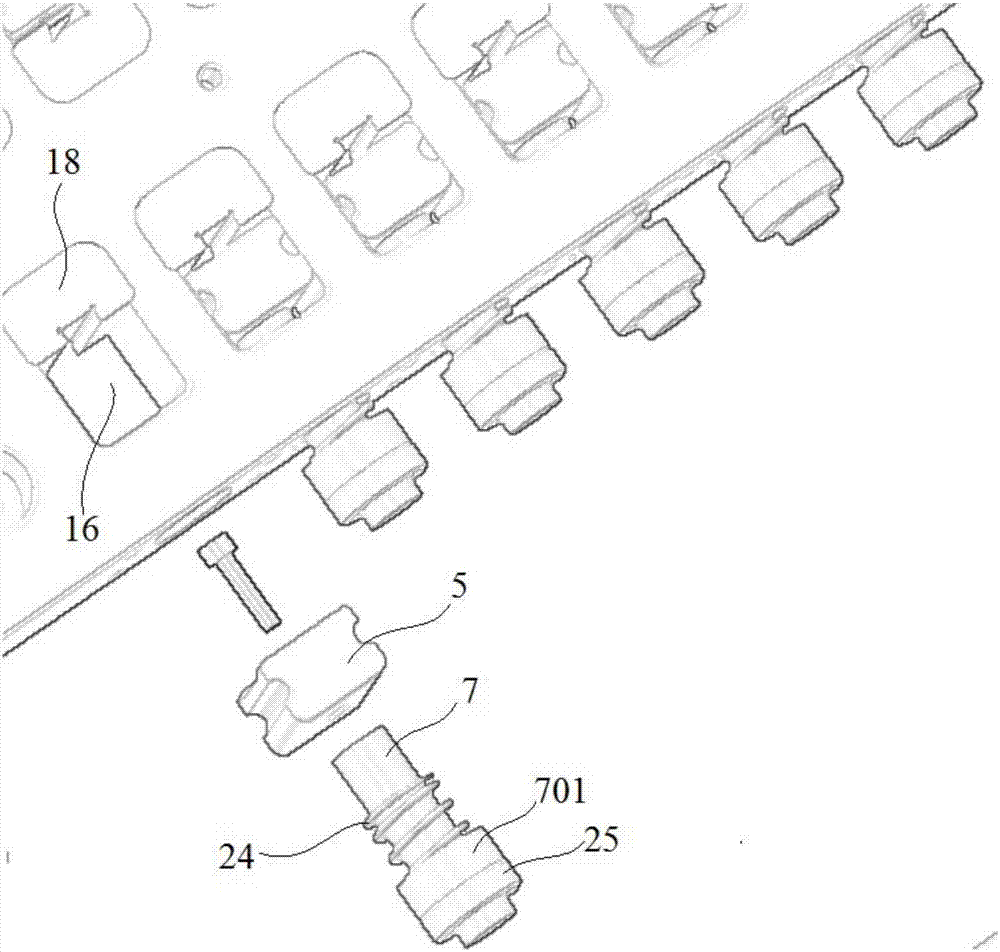

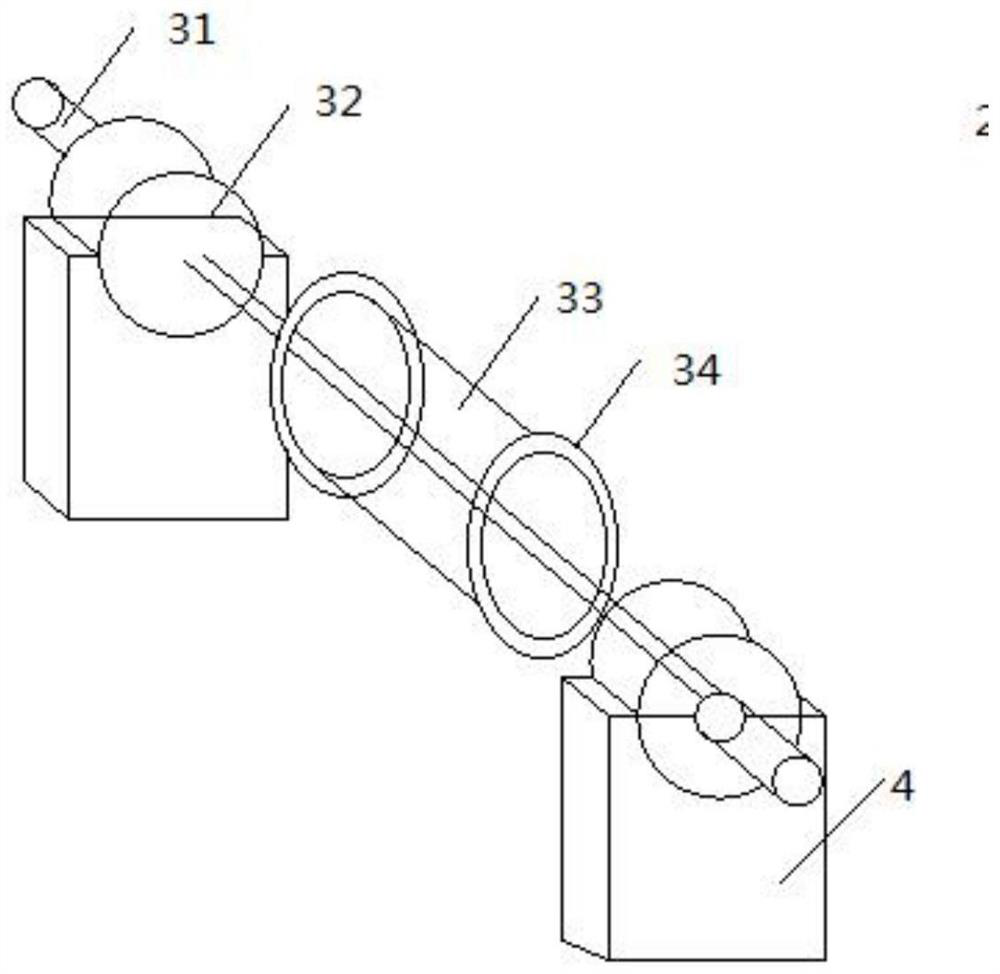

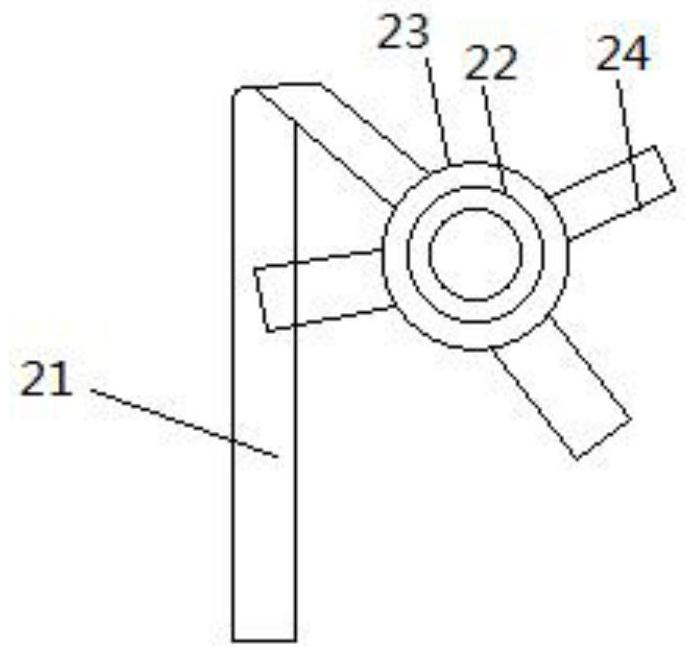

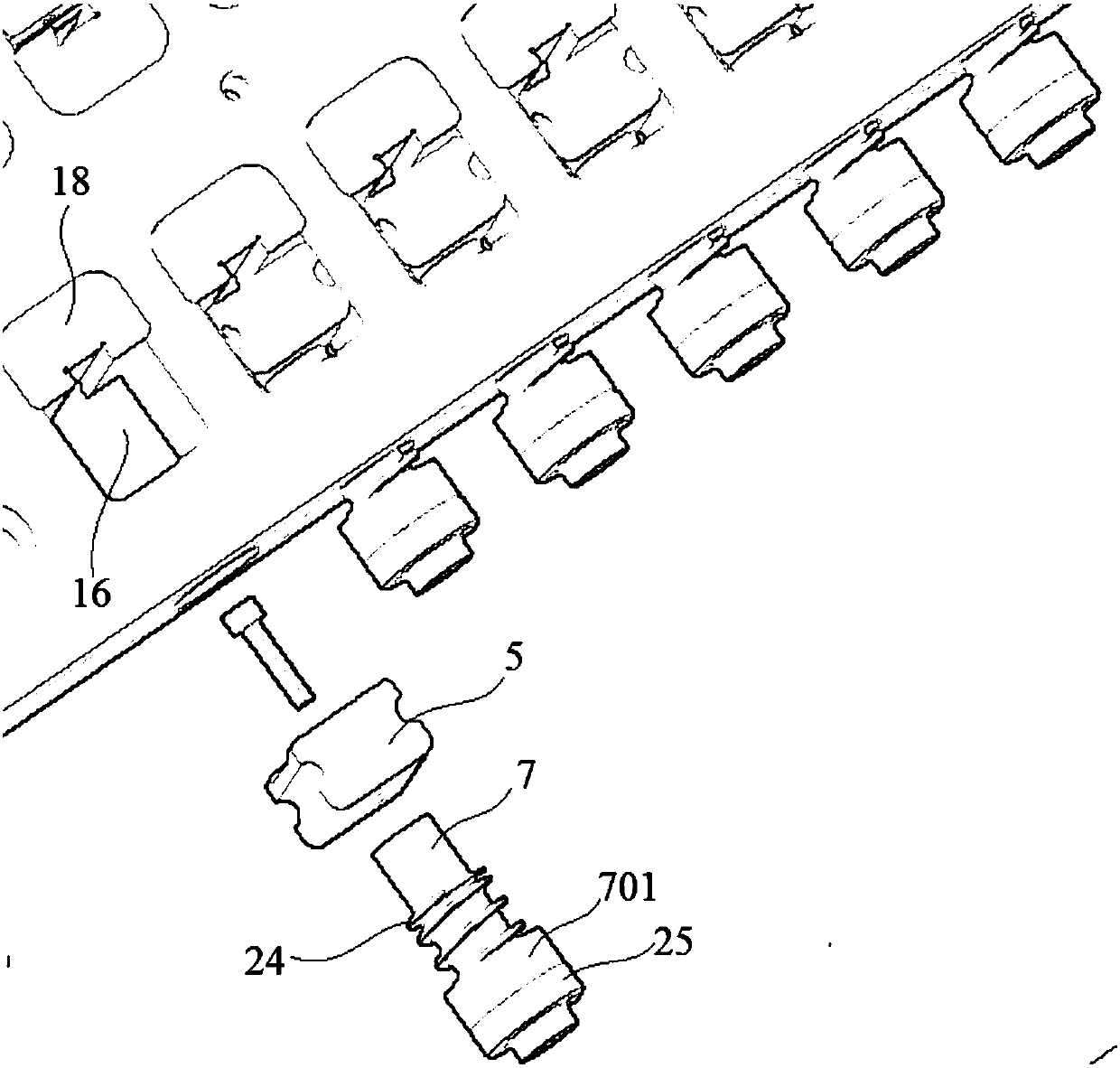

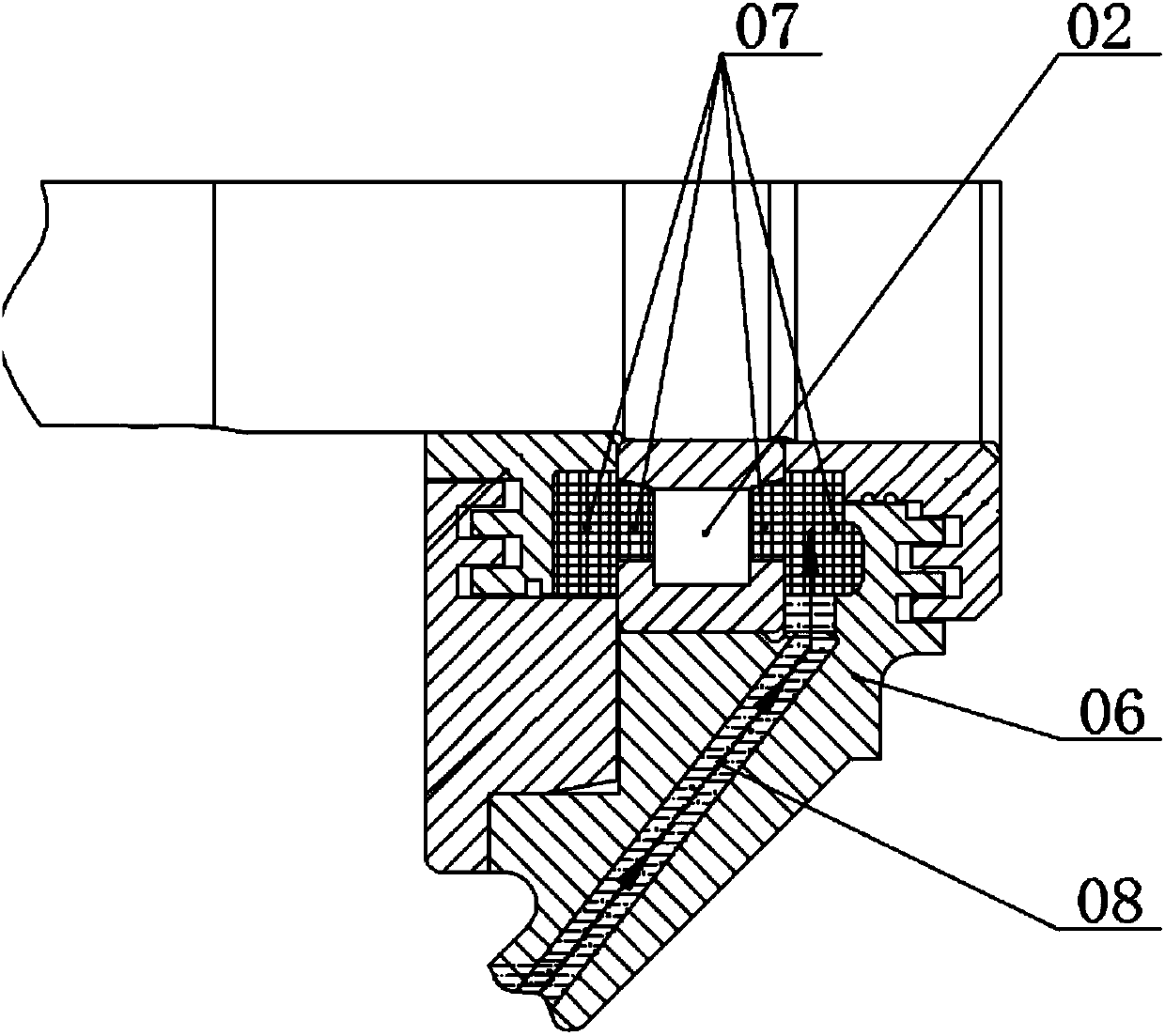

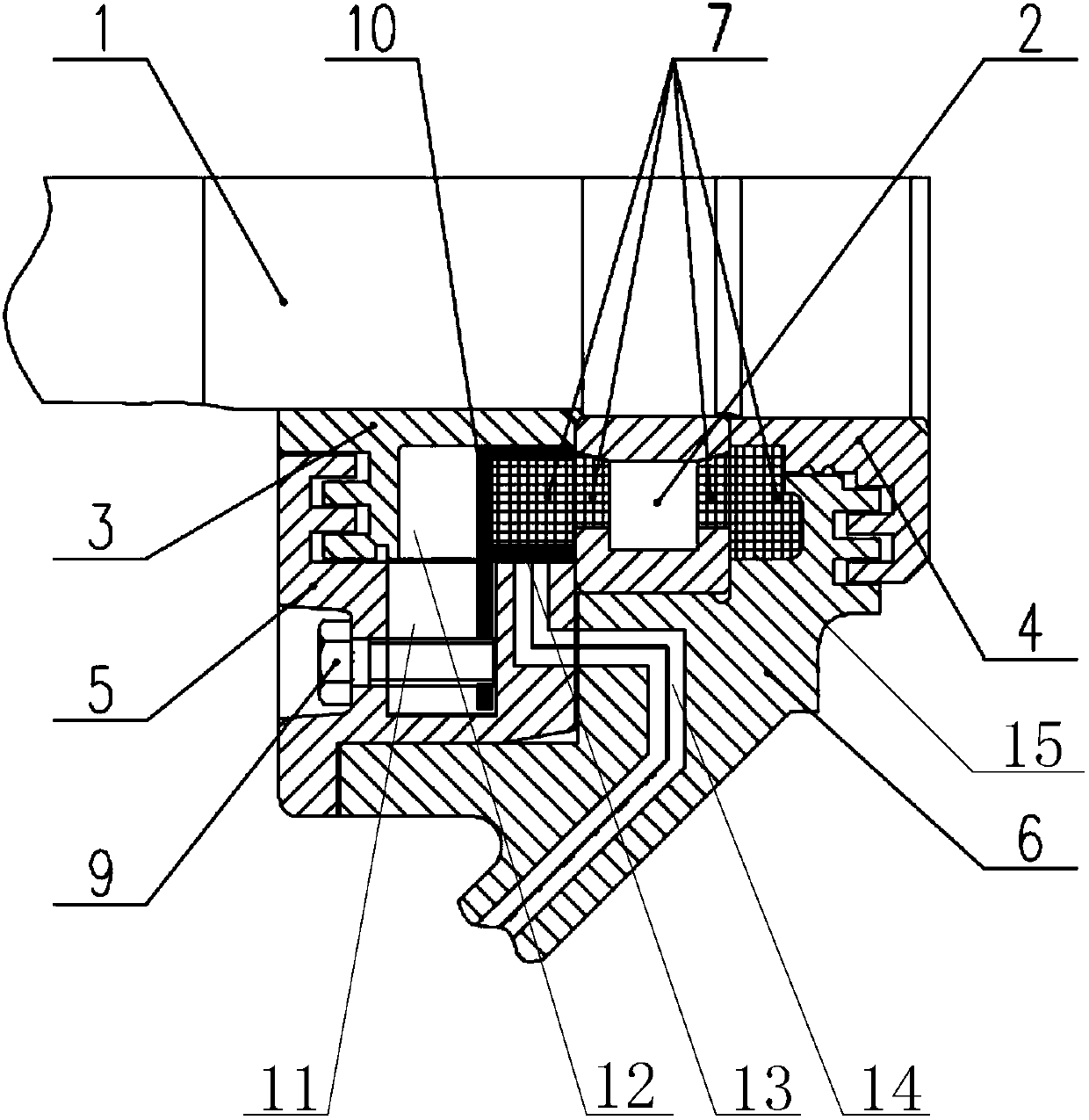

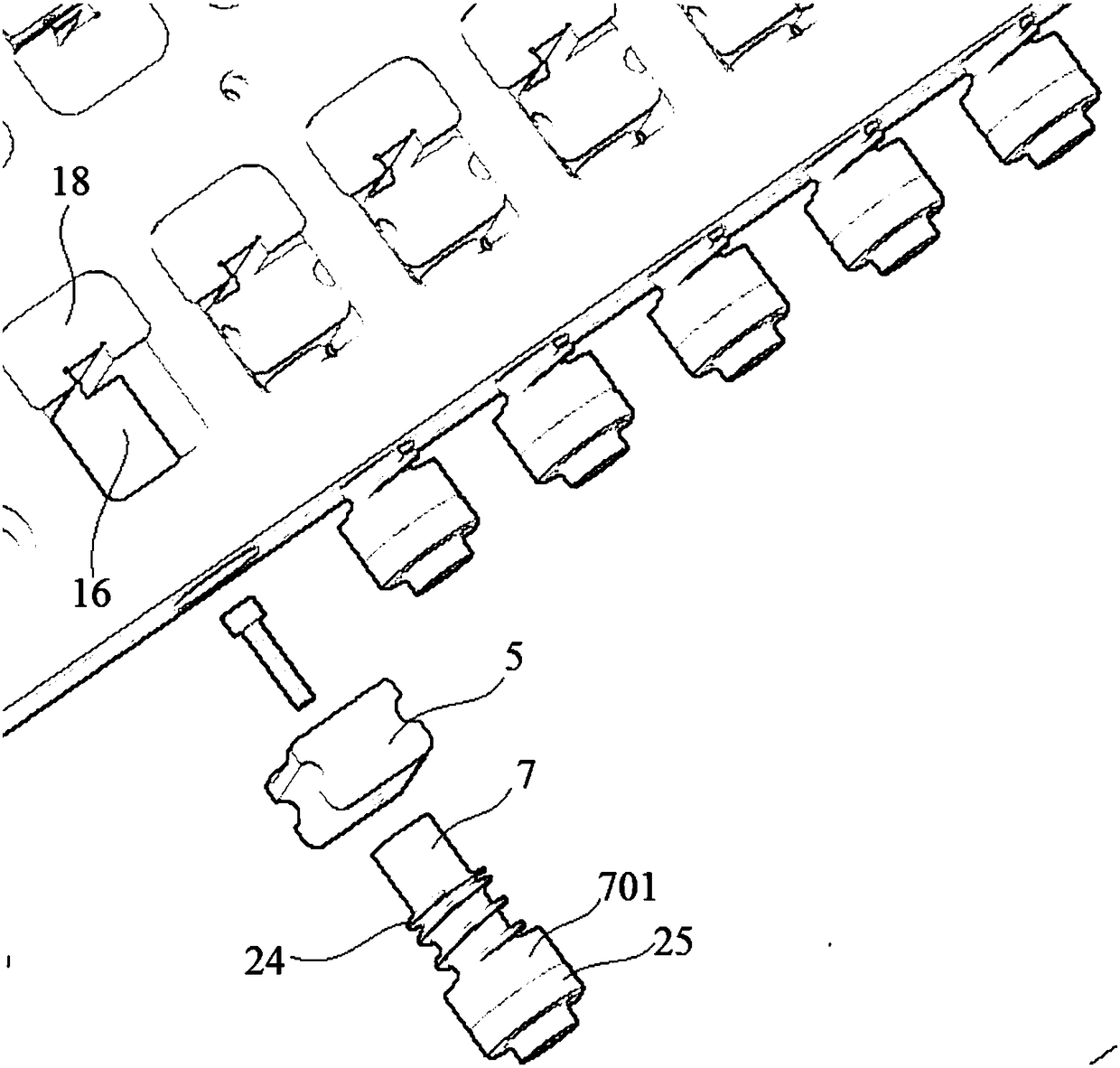

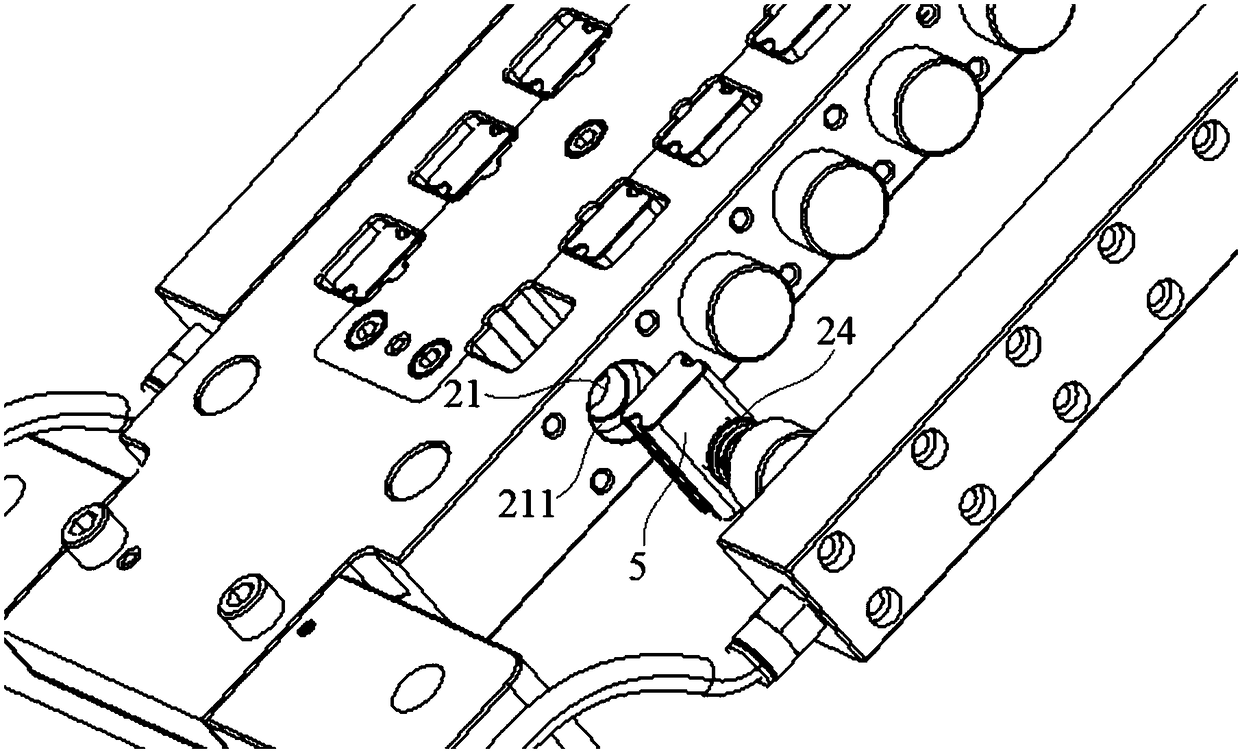

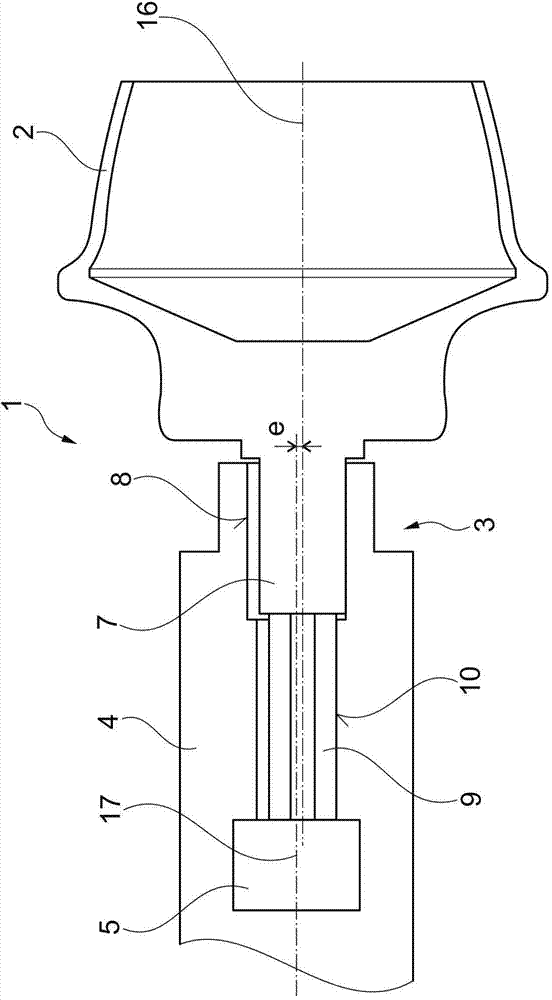

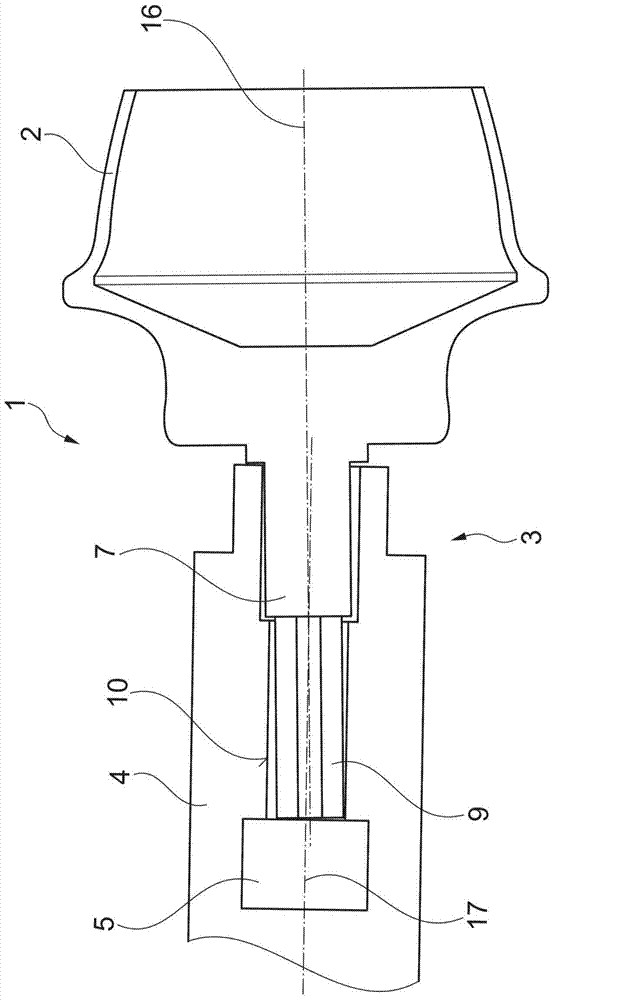

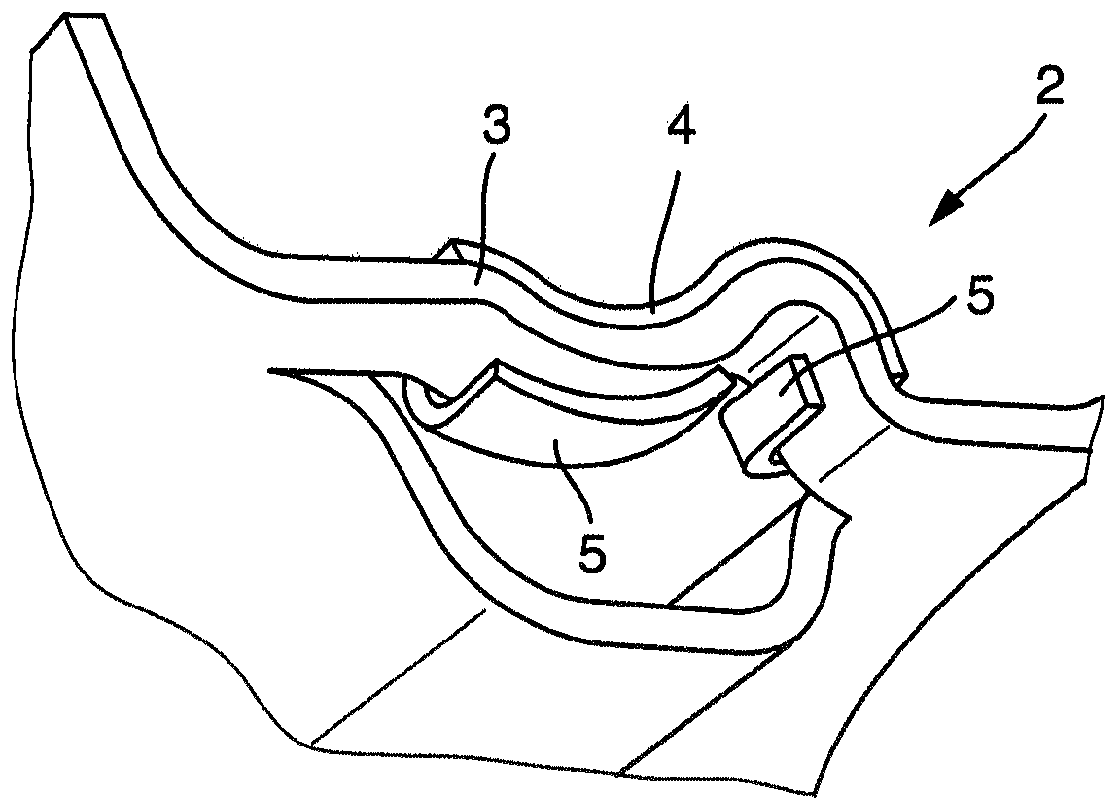

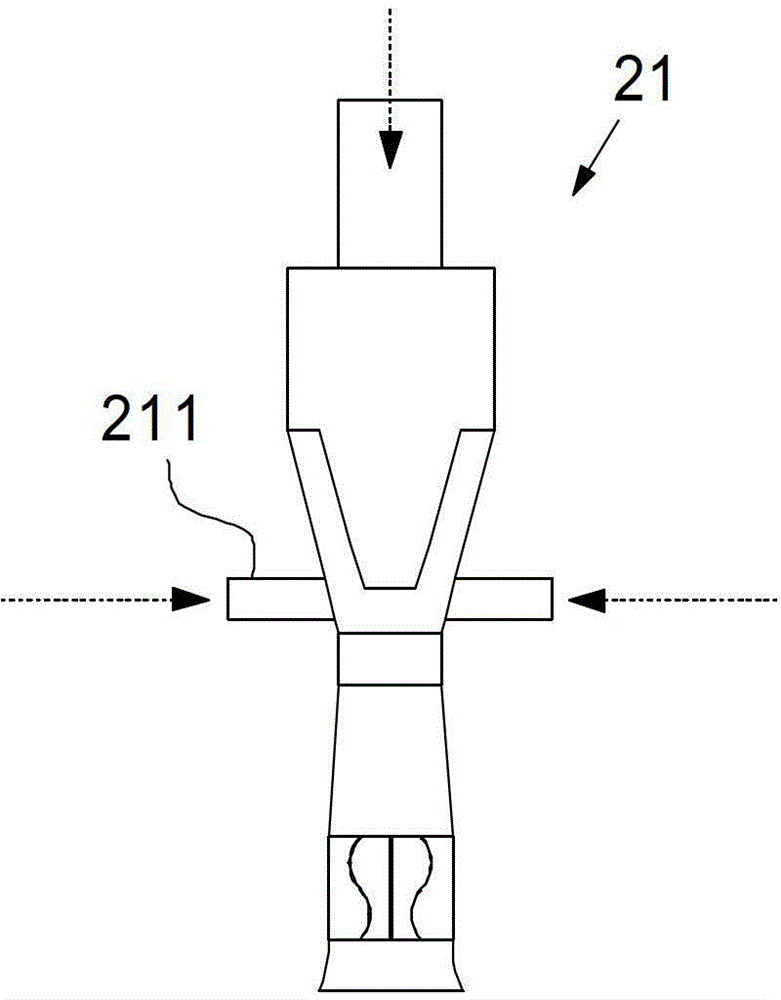

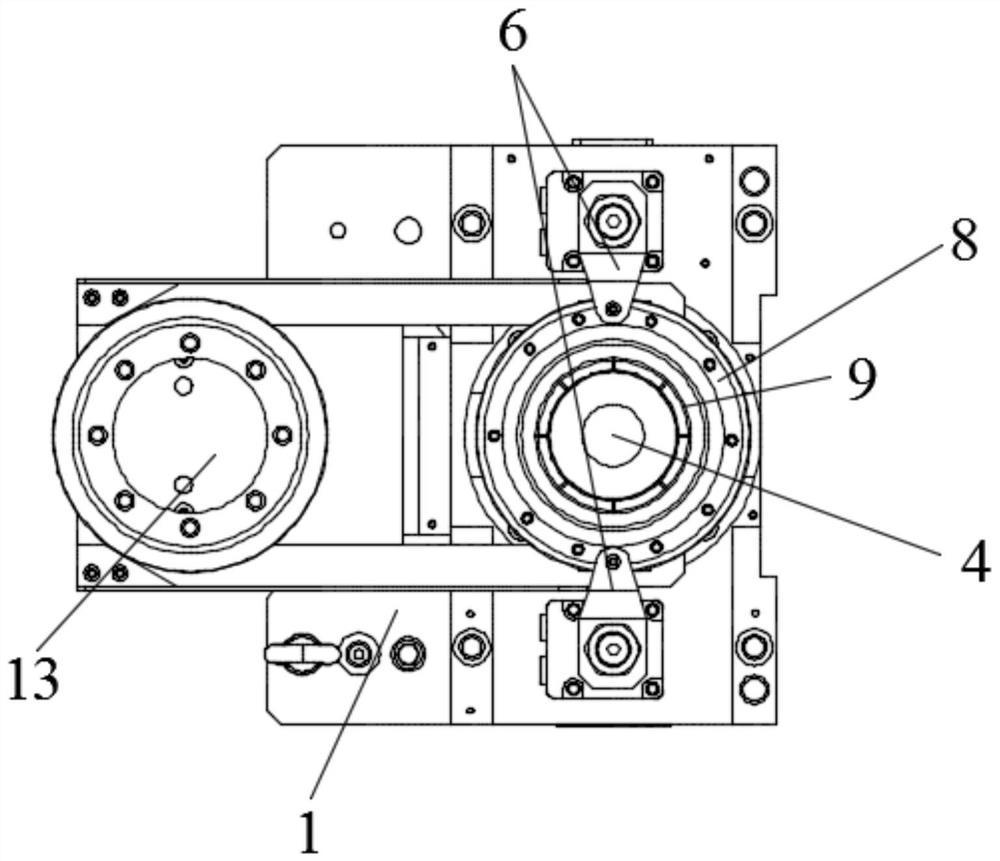

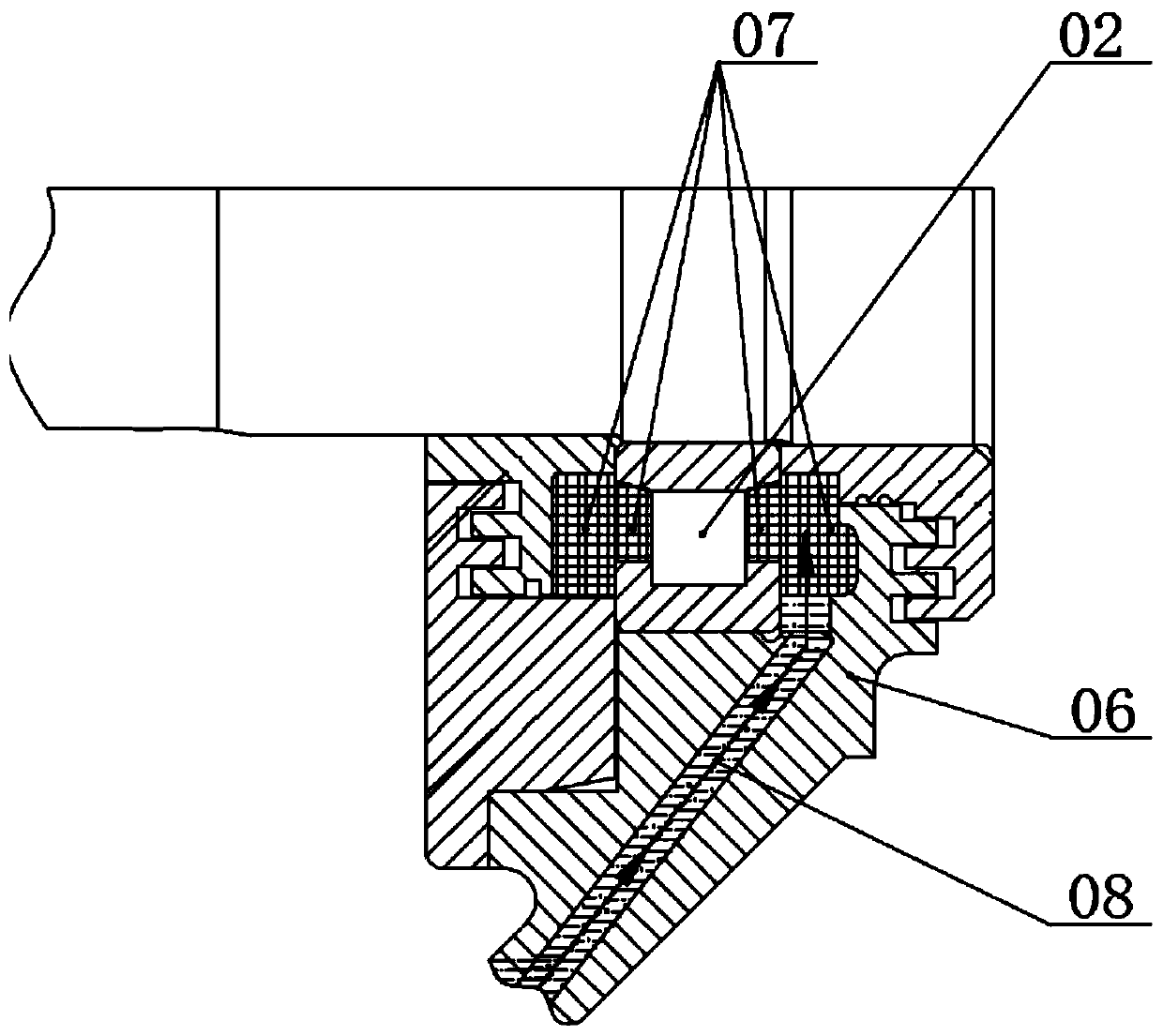

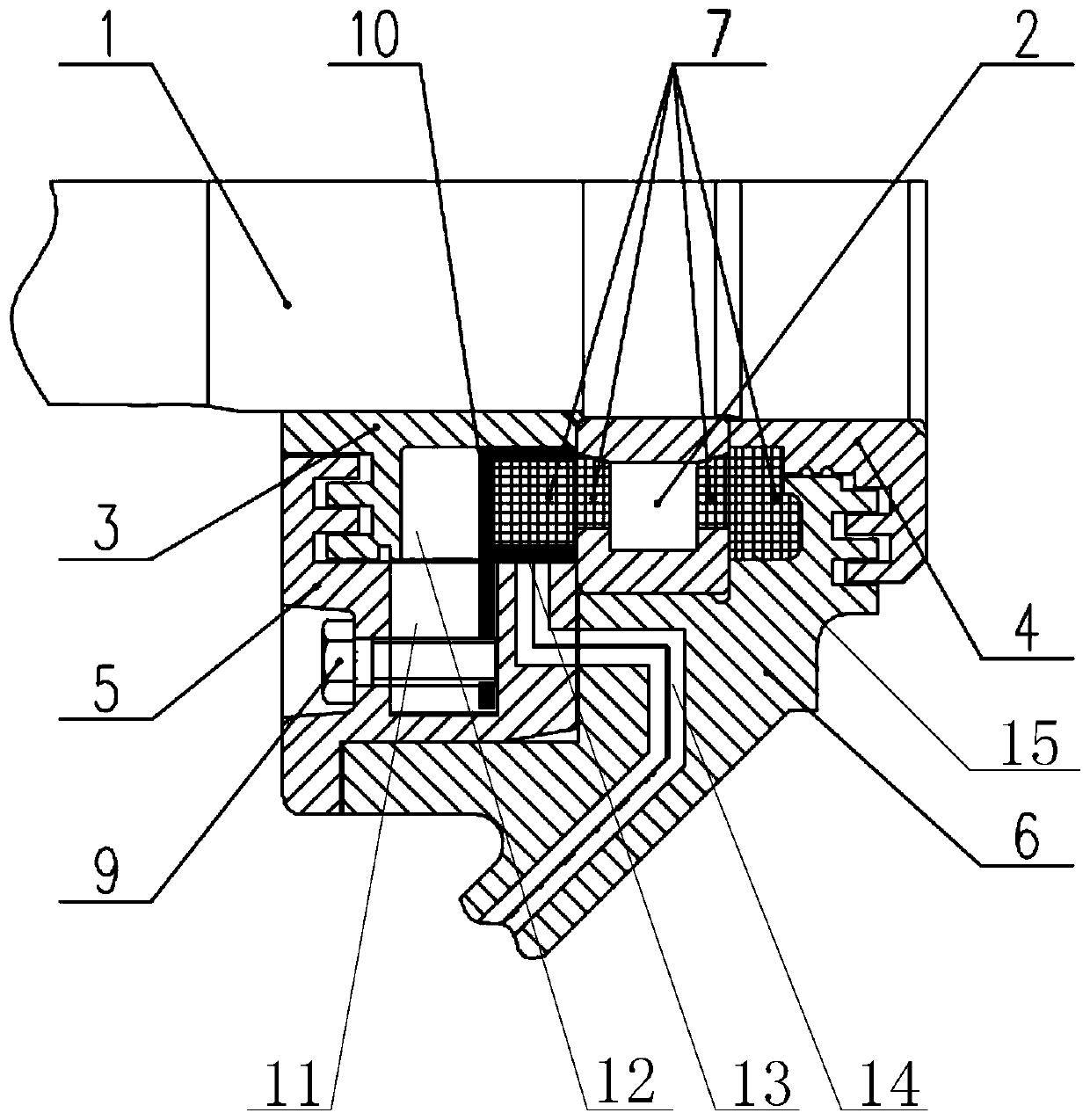

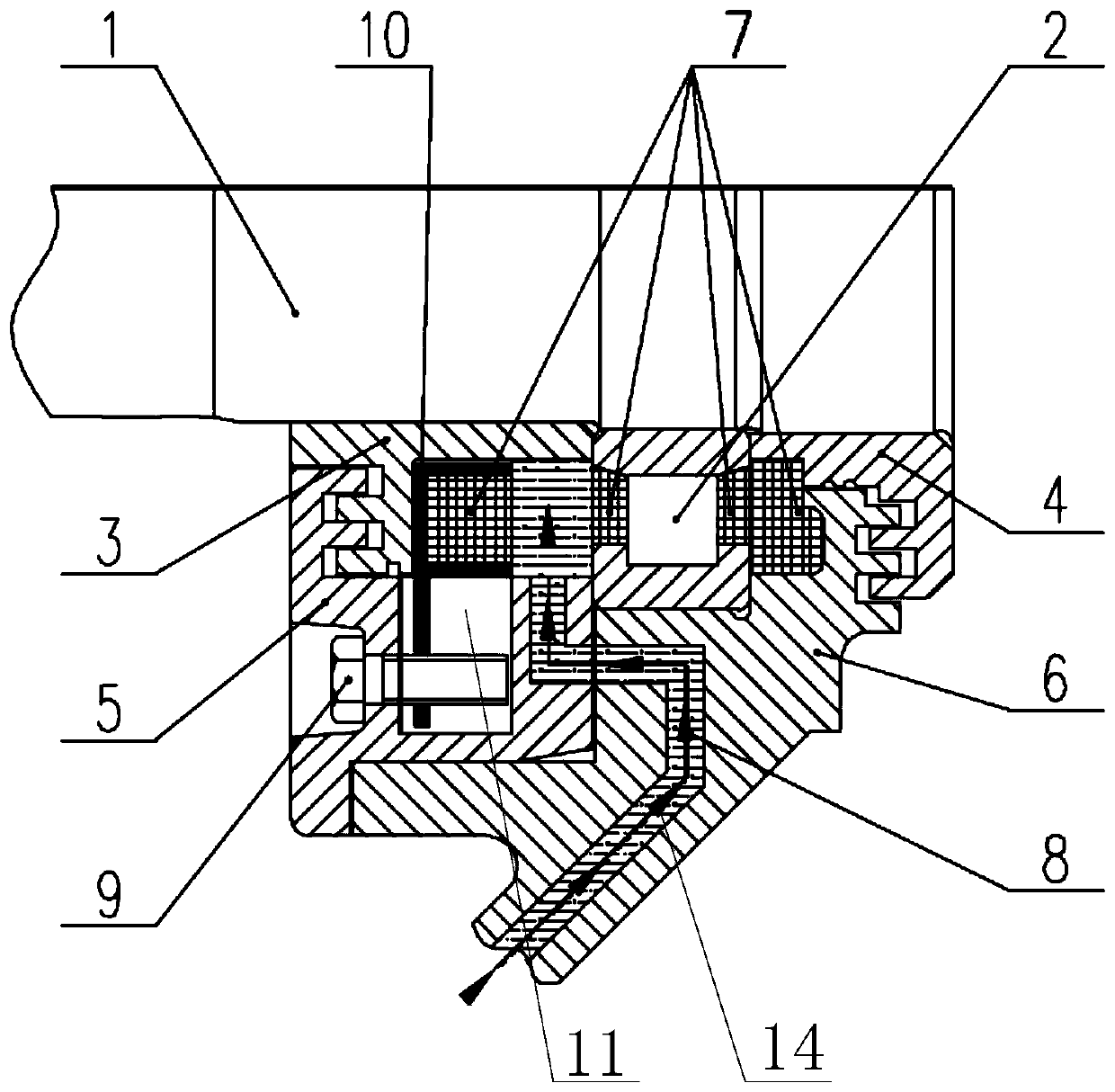

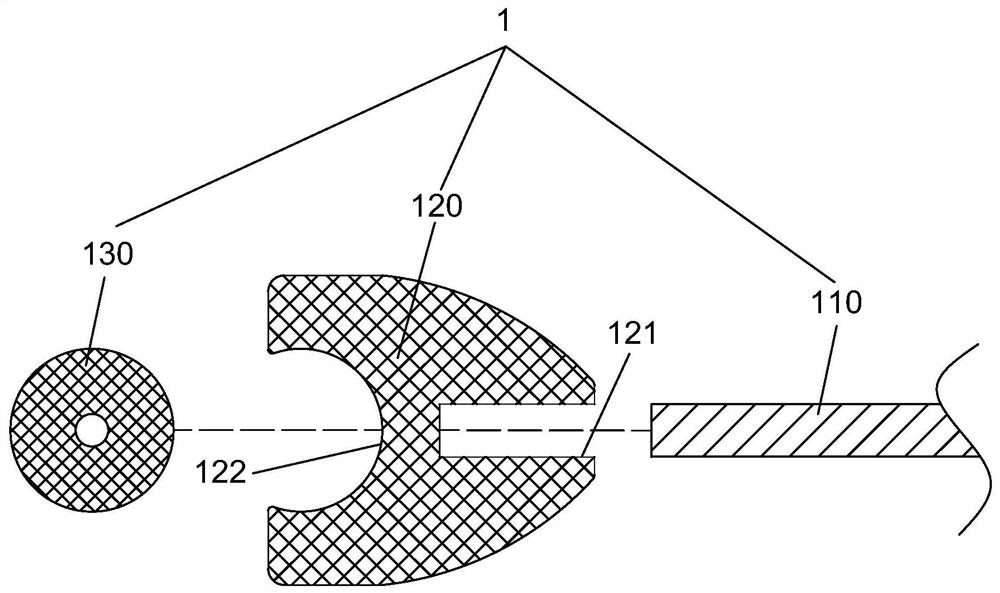

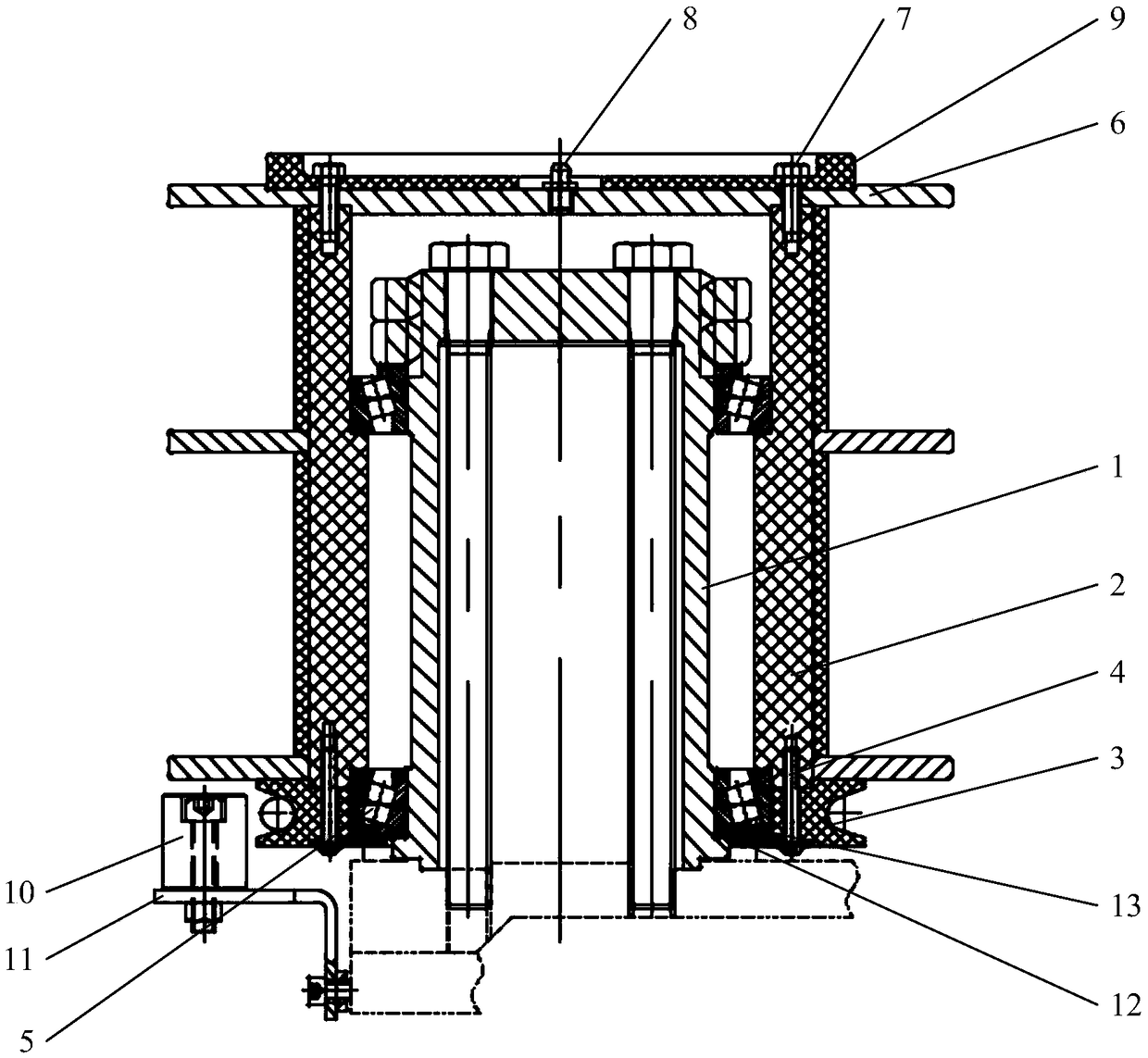

Open-end spinning rotor

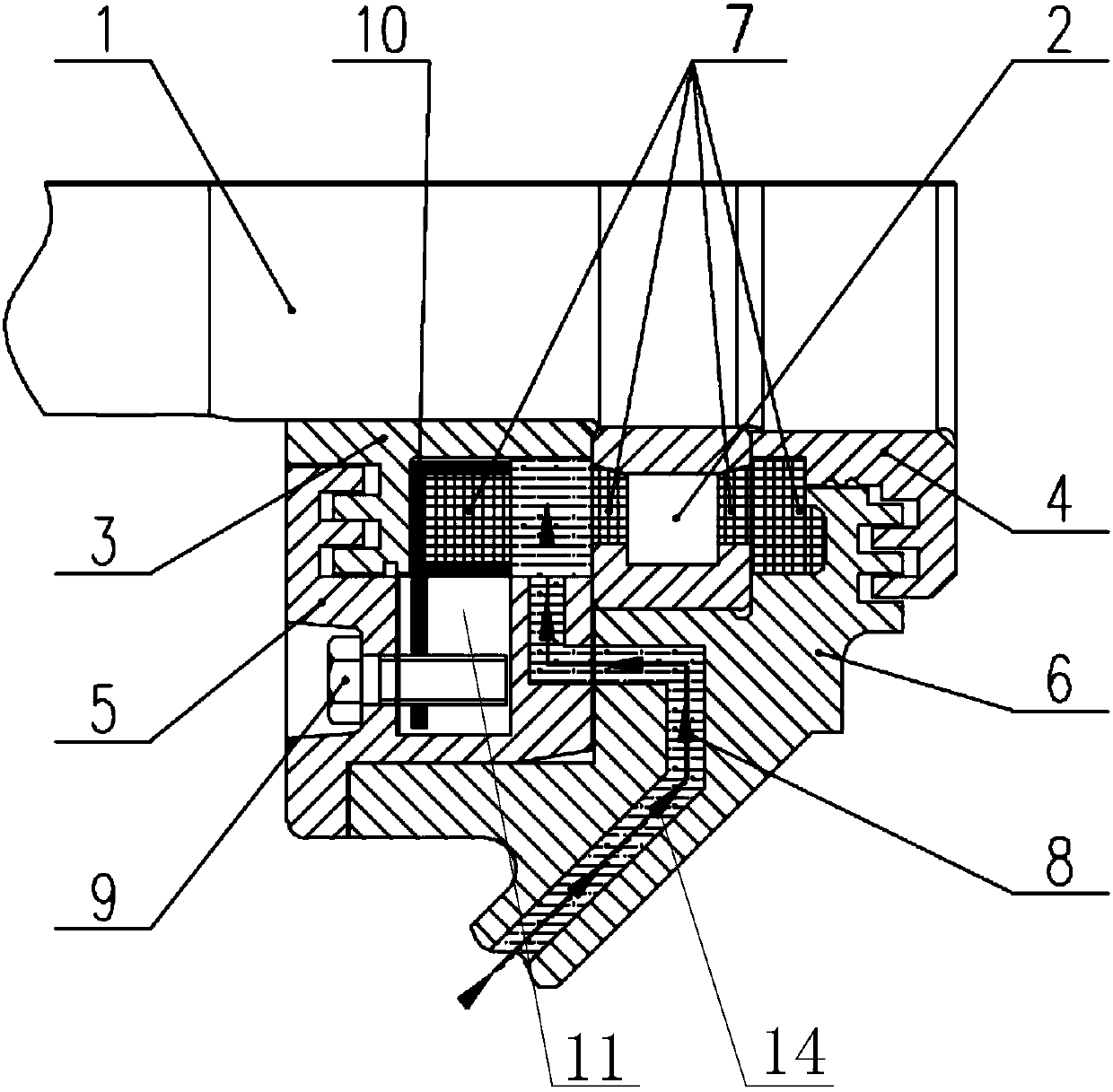

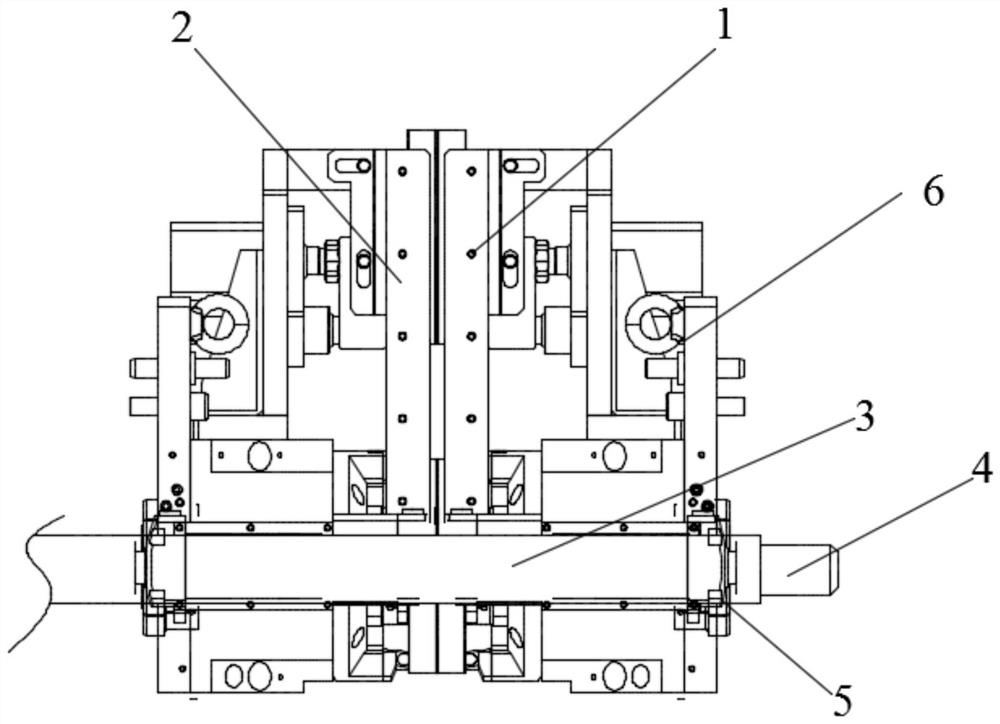

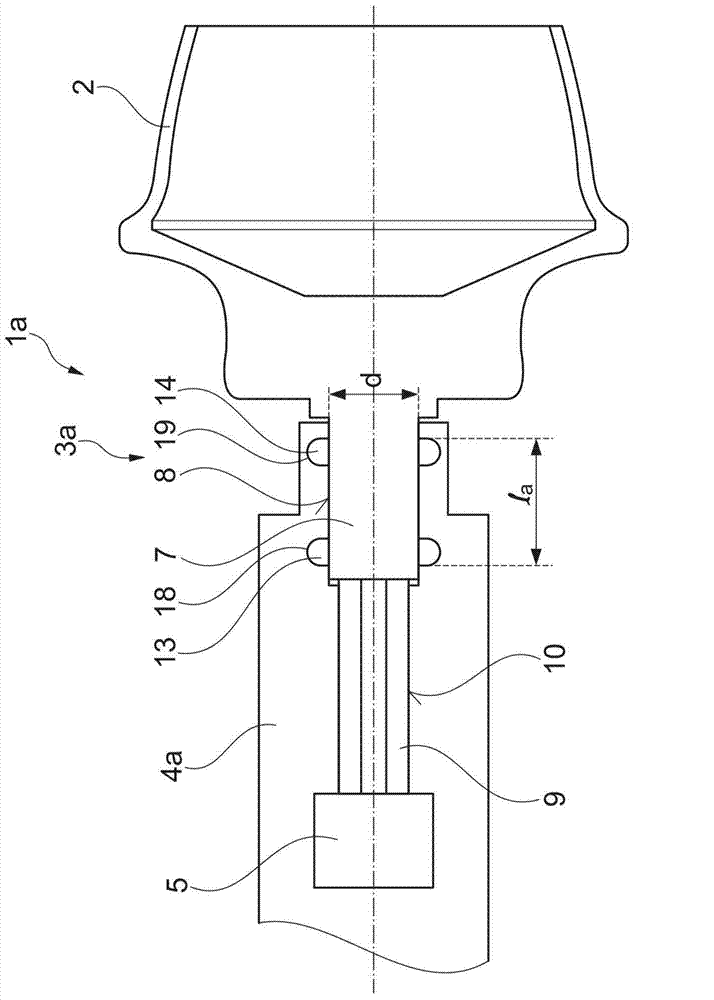

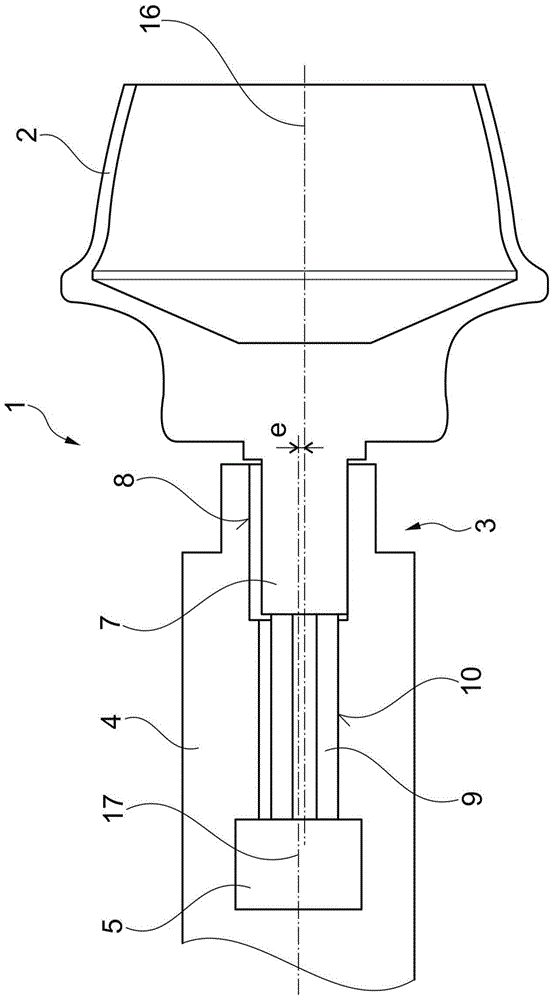

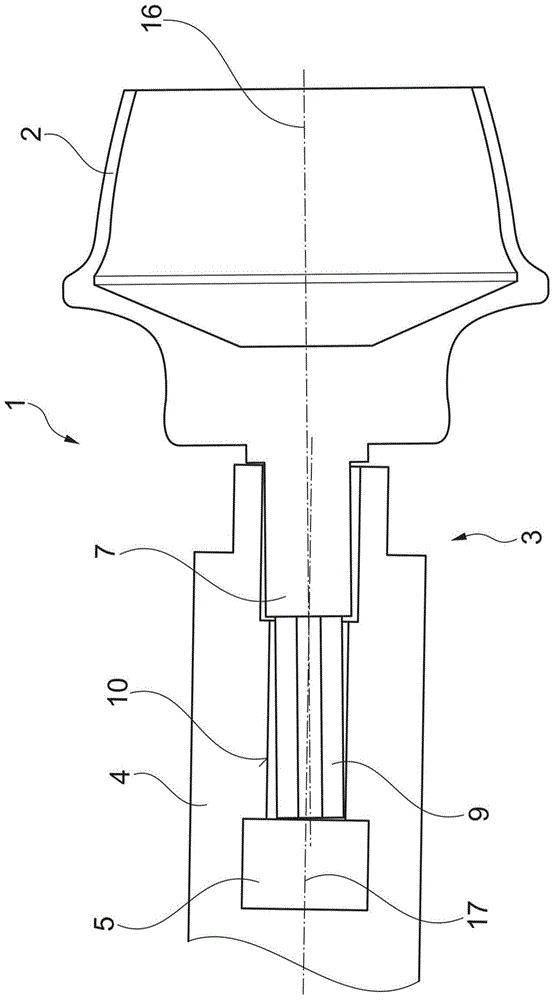

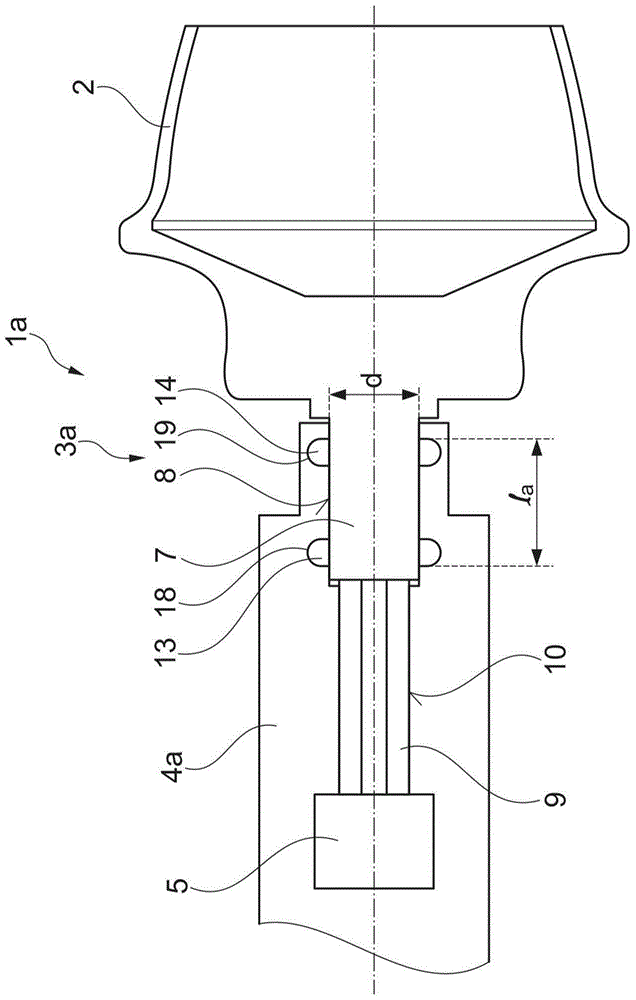

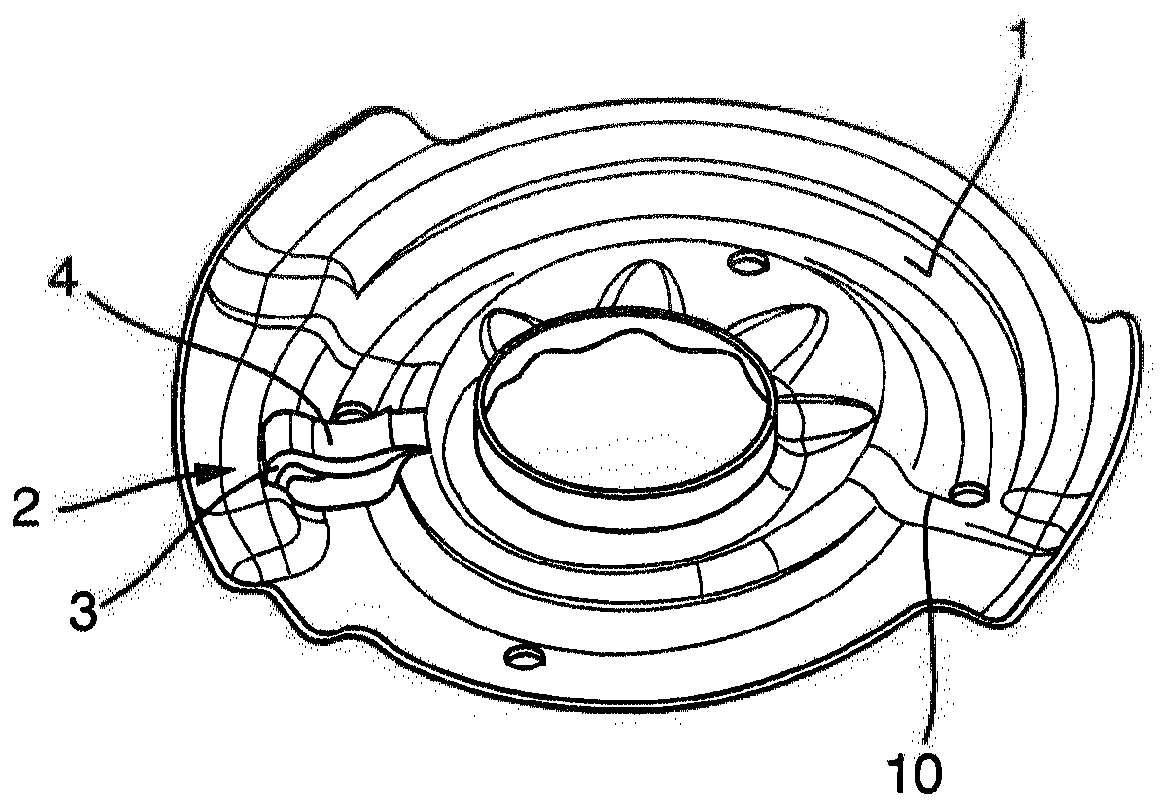

ActiveCN103806144AAvoid offsetGuaranteed replaceabilityContinuous wound-up machinesOpen-end spinning machinesEngineeringMechanical engineering

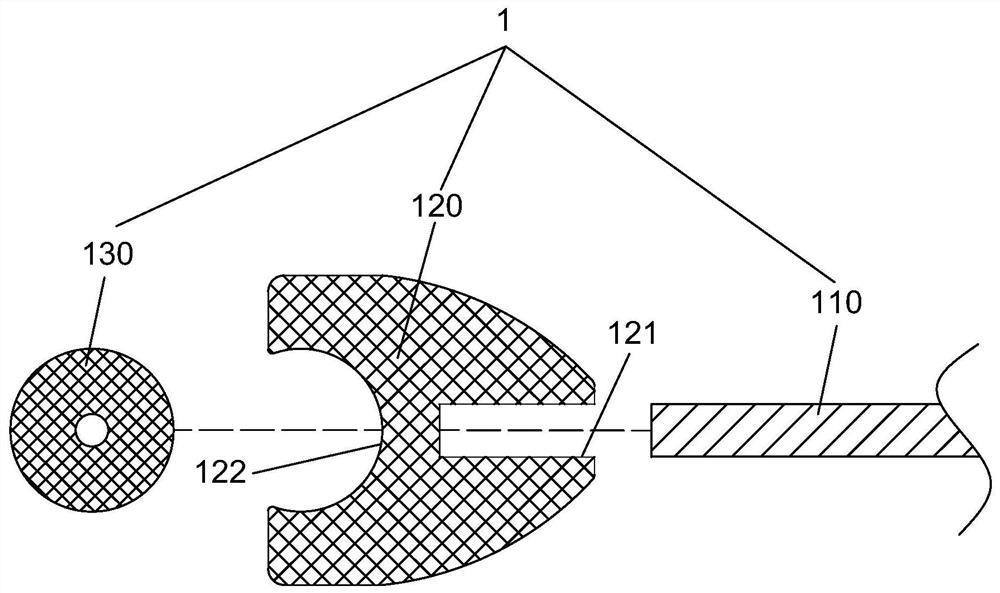

The invention relates to an open-end spinning rotor (1 a, 1 b, 1 c) comprising a rotor shaft (4a, 4b, 4c), a rotor cup (2, 2c) and a coupling device (3a, 3b, 3c). The rotor shaft (4a, 4b, 4c) and the rotor cup (2, 2c) are releasbly connected together by means of the coupling device (3a, 3b, 3c). The coupling device (3a, 3b, 3c) is provided with a locking means (5, 6) for the axial arresting of the rotor cup (2, 2c), a transmission means (9, 10, 11, 12) for positively transmitting a torque from the rotor shaft (4a, 4b, 4c) to the rotor cup (2, 2c), and a centering means used for aligning the rotor shaft (4a, 4b, 4c) with the rotor cup (2, 2c). The centering means comprises a cylindrical bore part (8, 8C) and a corresponding guide extension part (7, 7c) to be guided into the cylindrical bore part (8, 8C). According to the invention, the cylindrical bore part (8, 8C) and the guide extension part (7, 7c) are in clearance fit with each other. The centerin means comprises elastic arrangements (13, 14, 15B, 15c) arranged between the cylindrical bore part (8, 8C) and the guide extension part (7, 7c).

Owner:SAURER GERMANY GMBH & CO KG

Hydraulic clamping fixture for intelligent displayer accessory machining

InactiveCN109382686APrevent fallingPrevent slippingPositioning apparatusMetal-working holdersKnurlingDisplay device

The invention discloses a hydraulic clamping fixture for intelligent displayer accessory machining. The hydraulic clamping fixture comprises a left support, a right support, a fixed plate, a positioning plate, clamping heads and pressure mechanisms; the two ends of the fixed plate are fixedly connected with the left support and the right support respectively, the positioning plate is fixedly connected with the fixed plate, the clamping heads are located on the side away from the center, T-shaped blind holes corresponding to stepped holes are uniformly formed in the inner side surfaces of the pressure mechanisms, each hydraulic oil hole is connected with an oil pump through a hydraulic oil tube, the lower ends of guide pillars are connected with a left substrate of the left support and a right substrate of the right support respectively, two guide pillars located on the same side in the four guide pillars are anti-skid guide columns, a trapezoidal section is arranged on the side, closeto the exterior, of each anti-skid guide column, an included angle exists between each trapezoidal section and a vertical face, and the upper bottom of the trapezoidal section is shorter than the lower bottom. Accordingly, by means of knurling, the frictional force of the anti-skid guide columns is increased, the phenomenon that a movable plate slides downwards is effectively prevented, the stability of a to-be-machined material in the machining process is guaranteed, and the machining precision is guaranteed.

Owner:KUNSHAN KERSEN SCI & TECH

Open-end spinning rotor

InactiveCN103806144BGuaranteed replaceabilitySimple replaceabilityContinuous wound-up machinesOpen-end spinning machinesCouplingEngineering

The rotor (1) has a rotor cup (2) and a coupling setting (3) interconnected with a rotor shank (4). The coupling setting is provided with a locking part (5) for axial locking of the rotor cup. A transfer part (9, 10) transfers torque of the rotor shank to the rotor cup. A centering part centering the rotor shank and the rotor cup and provided with a cylindrical drilling and a guide set up. A flexible arrangement is arranged between the cylindrical drilling and the guide set up. Distance between the cylindrical drilling and the guide set up is less than 0.1 mm.

Owner:SAURER GERMANY GMBH & CO KG

Spring plate

ActiveCN111051726AInfiltration of dust particlesCan not penetrateSprings/dampers design characteristicsResilient suspensionsEngineeringSupport point

The invention relates to a spring plate for supporting a vehicle support spring, having a surface (1), which faces the vehicle support spring, and at least one supporting point (2), wherein the springplate has a region (3) which is set out from the surface (1) in the direction of the vehicle support spring and which forms the supporting point (2), and wherein a sheet metal element (4) acting as acorrosion protection element is fastened to the set-out region (3) and is in contact with the vehicle support spring in all operating states.

Owner:THYSSENKRUPP BILSTEIN +1

Hydraulic fixed fixture for ultra-thin fan metal piece machining

InactiveCN109382665ARealize automatic feedingReduce the use of laborWork clamping meansPositioning apparatusEngineeringMachining

The invention discloses a hydraulic fixed fixture for ultra-thin fan metal piece machining. The hydraulic fixed fixture comprises a left support, a right support, a fixed plate, a positioning plate, clamping heads and pressure mechanisms; the two ends of the fixed plate are fixedly connected with the left support and the right support respectively, the positioning plate is fixedly connected with the fixed plate, each oil seal sleeves a piston rod and is located between a flange portion and a switching surface of a T-shaped blind hole, at least two mounting through holes are formed in a movableplate, each telescopic cylinder is fixedly connected with the rear end surface of a shell, a piston rod of each telescopic cylinder penetrates through a connecting hole of the shell, each end, connected with a connecting rod, of a connecting block is provided with a connecting groove, a T-shaped part of each connecting rod is embedded into the corresponding connecting groove, and the flange of each T-shaped part is clamped with a clamping part of the corresponding connecting groove. According to the fixture, by arranging a telescopic mechanism, after all ejection operations are completed, anarc-shaped clamping jaw is pulled down backwards through the telescopic cylinder, so that a movable plate falls to the bottom surface, and loading is conducted again for the next round of machining;the structure is simple, operation is conducted conveniently and automatically, manpower and time are saved, and the work efficiency is improved.

Owner:KESEN SCI & TECH DONGTAI CO LTD

Steel tube concrete truss composite beam with detachable bridge deck and construction method

ActiveCN106758750BBroaden the field of applicationGuaranteed replaceabilityTruss-type bridgeBridge structural detailsBridge deckSteel tube

The invention relates to a concrete filled steel tube truss composite beam with detachable bridge deck slabs and a construction method thereof. The concrete filled steel tube truss composite beam is characterized by further comprising the plurality of detachable bridge deck slabs sequentially paved at the upper part of the steel tube truss along with the direction of a bridge, wherein upper bent tubes are arranged at the upper part of the steel tube truss, a plurality of connection board sets are fixed on the upper bent tubes, and the connection boards are provided with screw holes; positioning grooves in one-to-one correspondence with the plurality of connection board sets and anchoring holes in one-to-one correspondence with the screw holes are arranged at the lower part of the bridge deck slabs; and each two adjacent bridge deck slabs are anchored and connected via a gear deadbolts. According to the concrete filled steel tube truss composite beam with detachable bridge deck slabs provided by the invention, replacement of the bridge deck slabs is facilitated when the bright is in use, the construction cycle is shortened, the construction difficulty is reduced, the construction quality and personnel safety can be ensured, and the requirement on construction site can be reduced.

Owner:TIANJIN CHENGJIAN UNIV

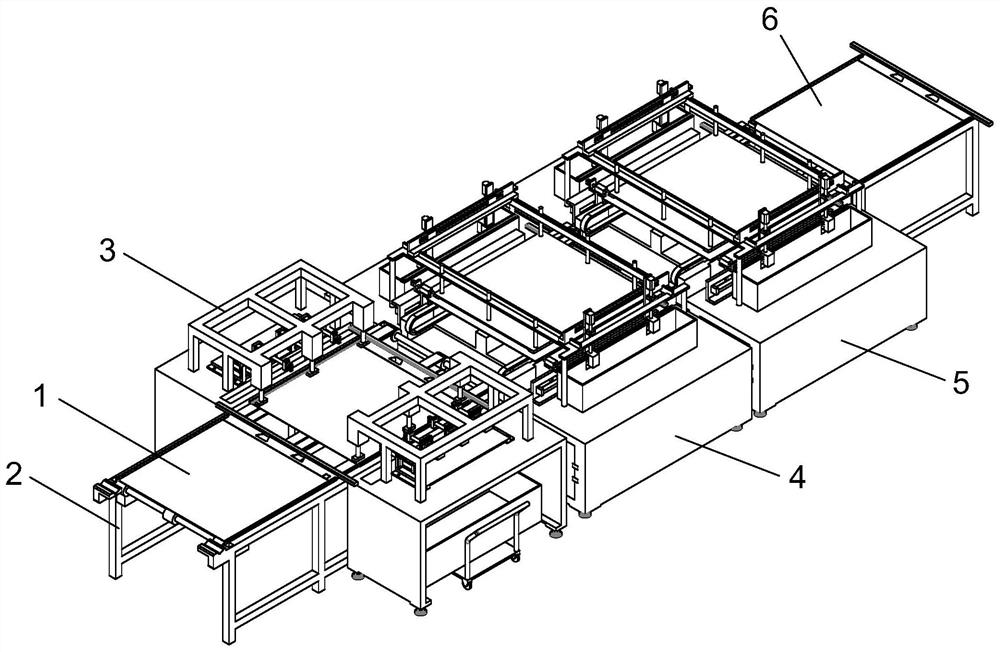

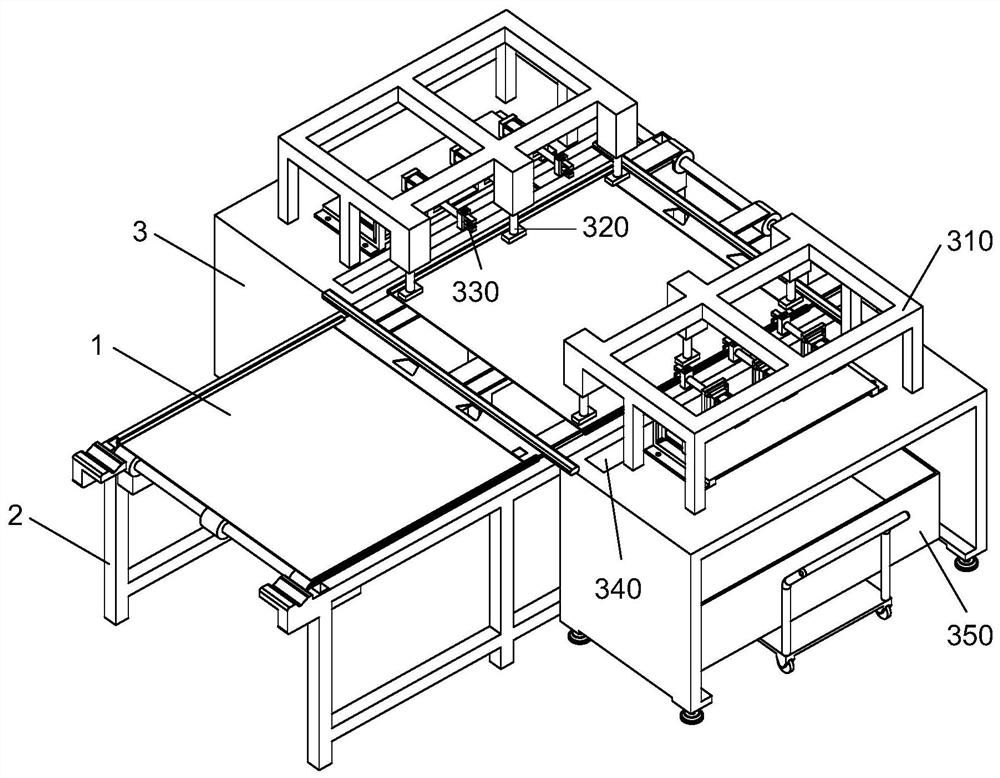

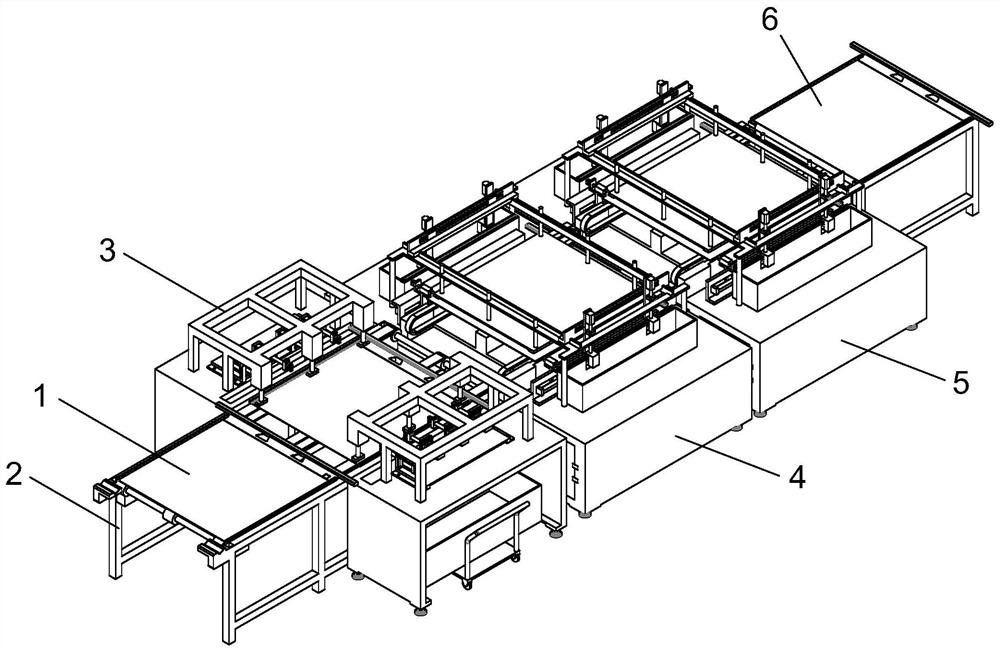

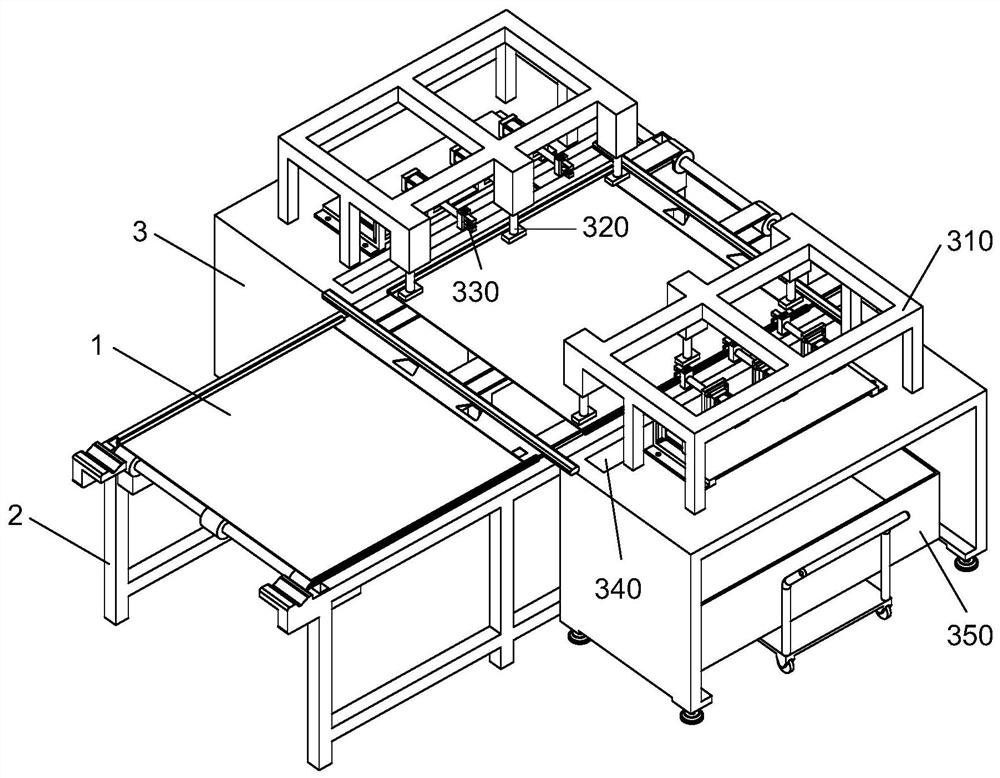

Device for automatically replacing edge clamping strips and expansion strips of cathode plate

ActiveCN111926350AQuick releaseEliminate manual disassemblyPhotography auxillary processesProcess efficiency improvementStructural engineeringCcd camera

The invention provides a device for automatically replacing edge clamping strips and expansion strips of a cathode plate. The device comprises a feeding platform, a dismounting platform, an edge clamping strip mounting platform and an expansion strip mounting platform, wherein the platforms are connected through a conveyor belt and communicate with a controller; the top surface of the dismountingplatform is provided with a dismounting fixing frame, a pressing block and a dismounting mechanism; and the dismounting mechanism is arranged below the dismounting fixing frame and comprises a plurality of dismounting claws, and the two sides of the edge clamping strip mounting platform are provided with positioning and clamping mechanisms, feeding mechanisms, taking mechanisms, CCD cameras and mounting mechanisms. The taking mechanisms are provided with turnover taking claws, the turnover adjustment can be carried out before and after taking through matching with the CCD cameras, consequently, the consistency of the orientation of the edge clamping strips is guaranteed, and one ends of the edge clamping strips are firstly pressed into a stainless steel plate through matching of an edge clamping strip opening block and a pressing roller, and then are sequentially pressed into the cathode plate by the pressing roller, so that the installation of the edge clamping strips is achieved, anddamage to the edge clamping strips is avoided without knocking, and the stability in the electrolysis process is guaranteed.

Owner:鹰潭市智汇物联网应用研究院有限公司

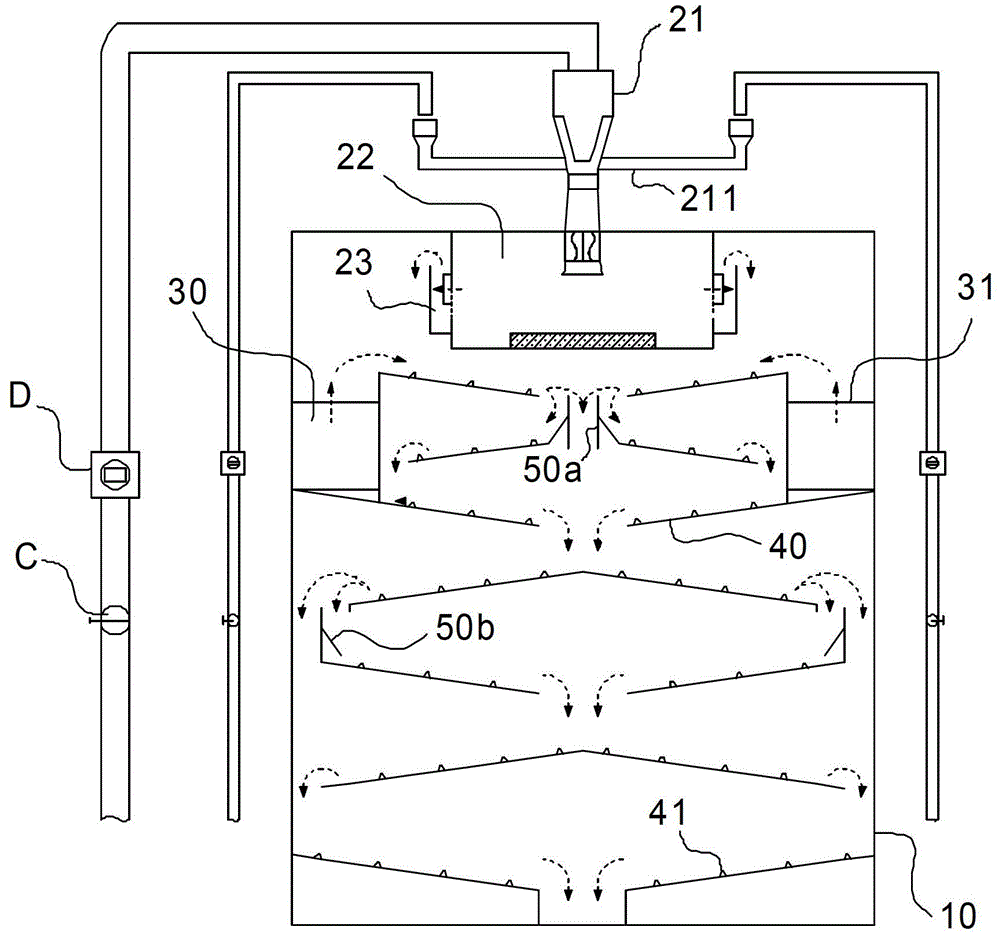

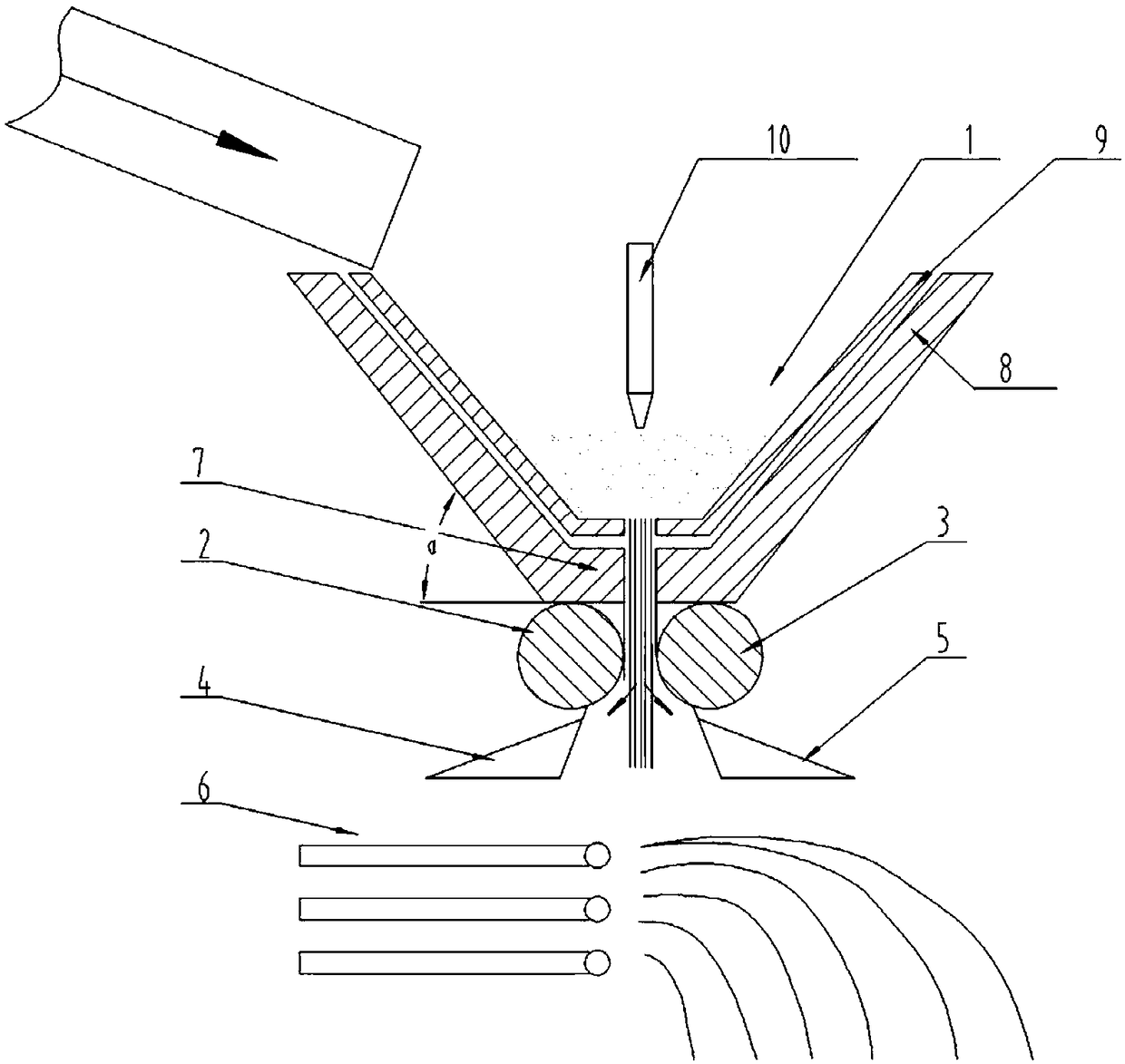

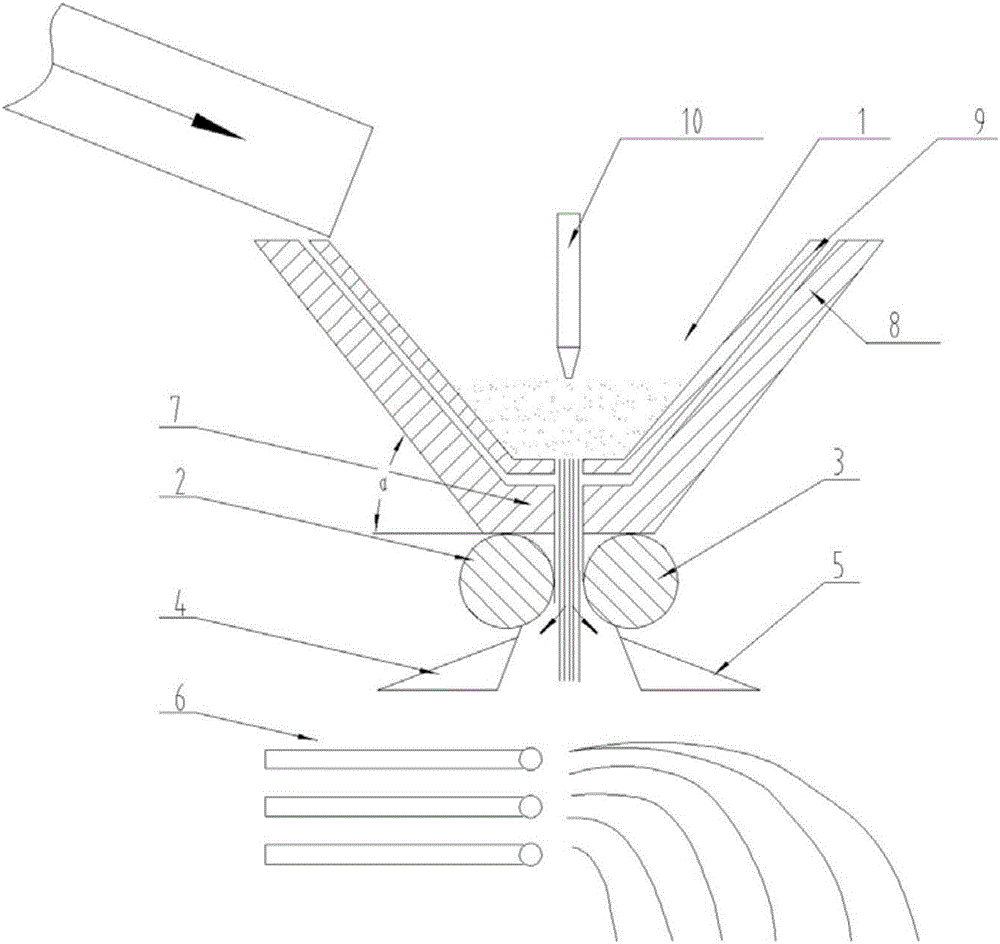

Classifying dropping-type coal slurry pretreating device

The invention belongs to the field of coal slime powder pretreating, and specifically relates to a classifying dropping-type coal slurry pretreating device. The classifying drop-type coal slurry pretreating device provided by invention at least comprises a dropping box and a classifying dropping system, wherein a flotation agent feeding part and a coal slurry feeding part are correspondingly arranged above the classifying dropping system, the classifying dropping system comprises sliding plates which are arranged in a space layering manner, and the sliding plates which are arranged in a layer-by-layer manner are joined each other from head to end so as to form a channel for mixing and traveling of coal slurry and a flotation agent. The device also comprises a splitting unit, wherein the splitting unit is at least arranged on the discharge end of one layer of sliding plate, and the splitting end of the splitting unit is positioned on the layering surface of dropping paths of low-ash-content coarse granules and high-ash-content fine clay of the coal slurry on the layer of sliding plate. Through a stripping effect of the splitting unit on high-ash-content fine clay and low-ash-content coarse granules, the pollution of the high-ash-content fine clay to floatation fine coal is farthest lightened, the operating efficiency of the classifying dropping-type coal slurry pretreating device is improved, meanwhile, the practical input amount of the flotation agent is also greatly reduced, and the control on the pretreating cost is facilitated.

Owner:嘉善永升五金厂

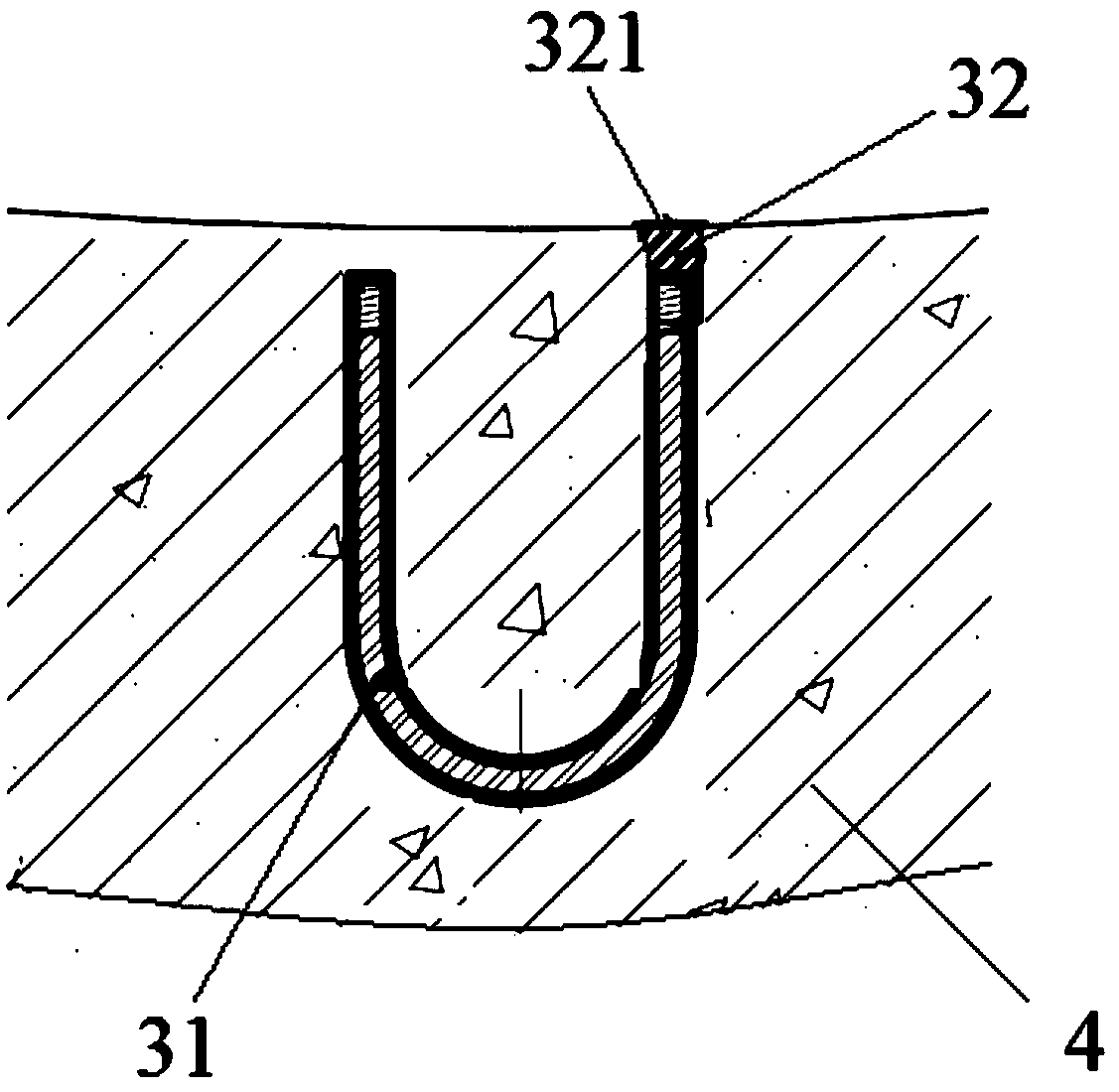

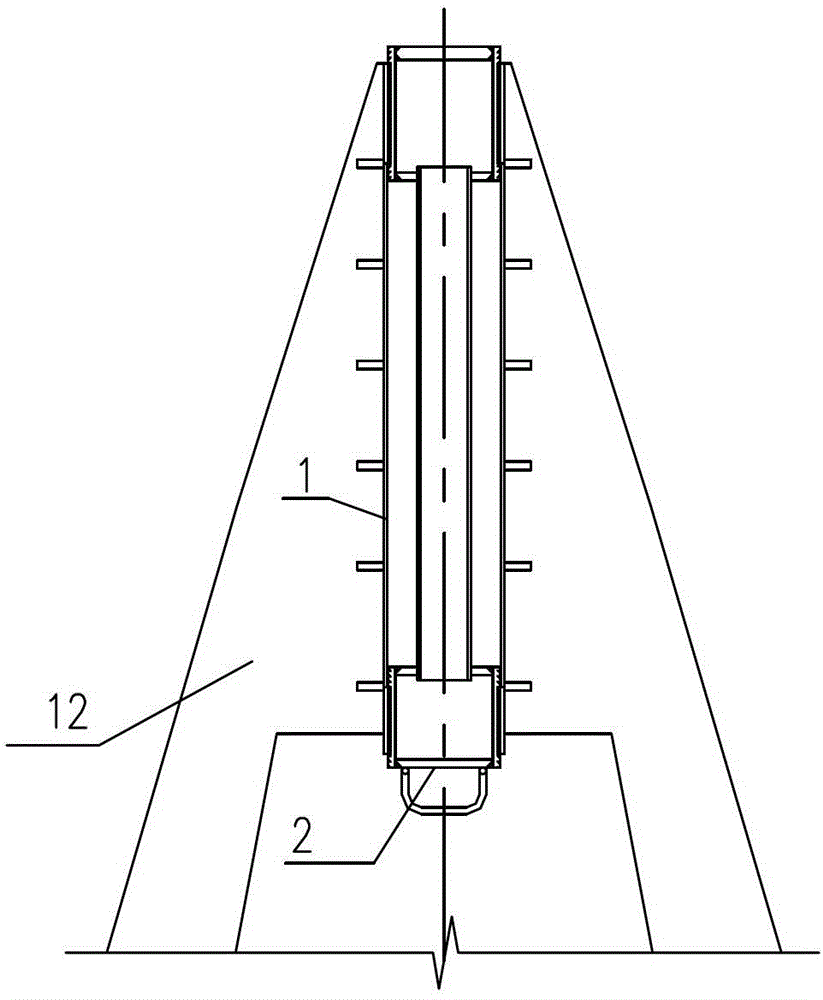

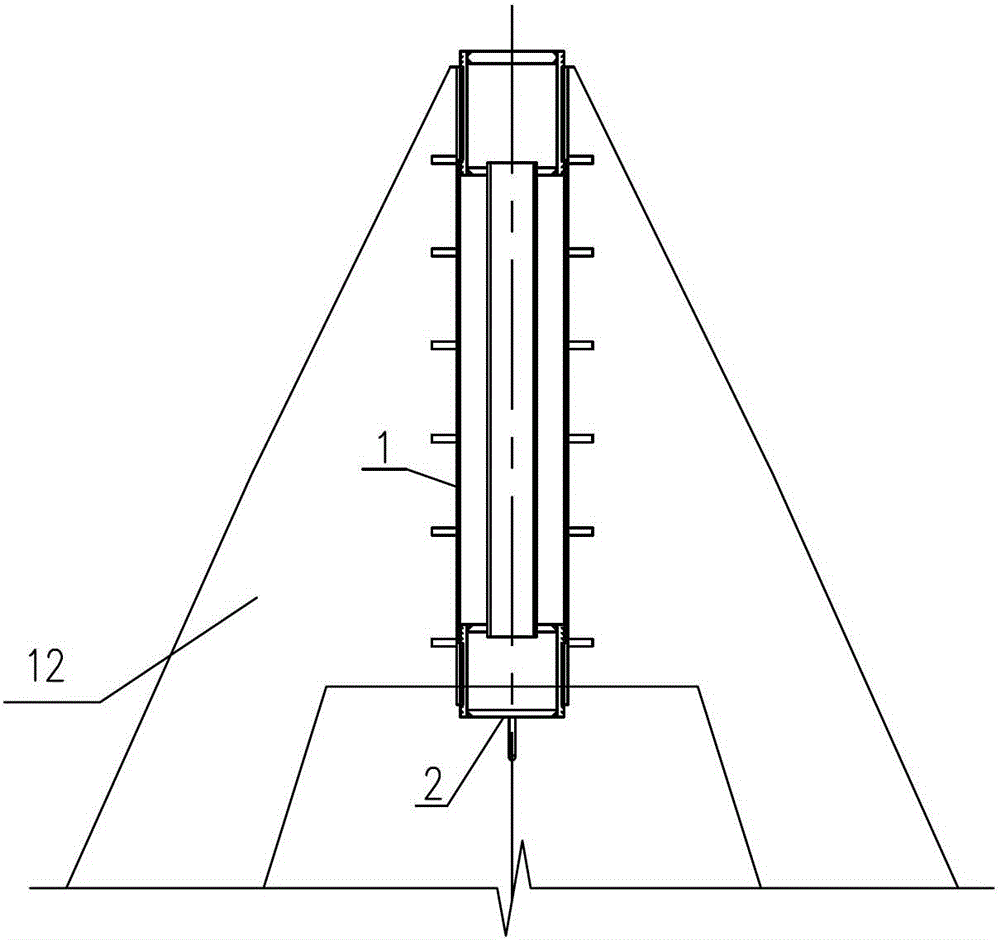

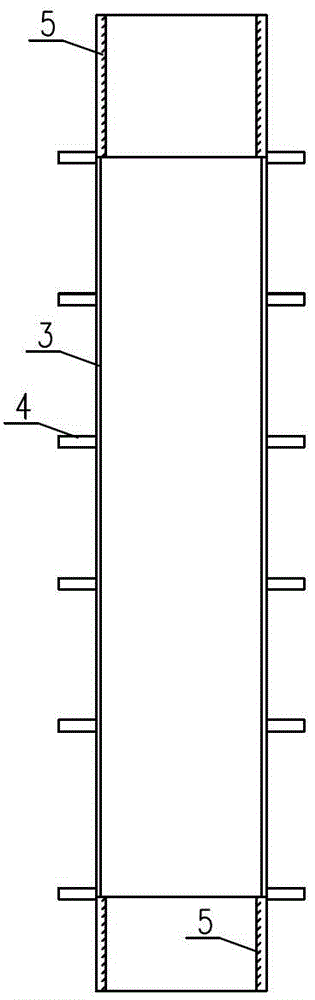

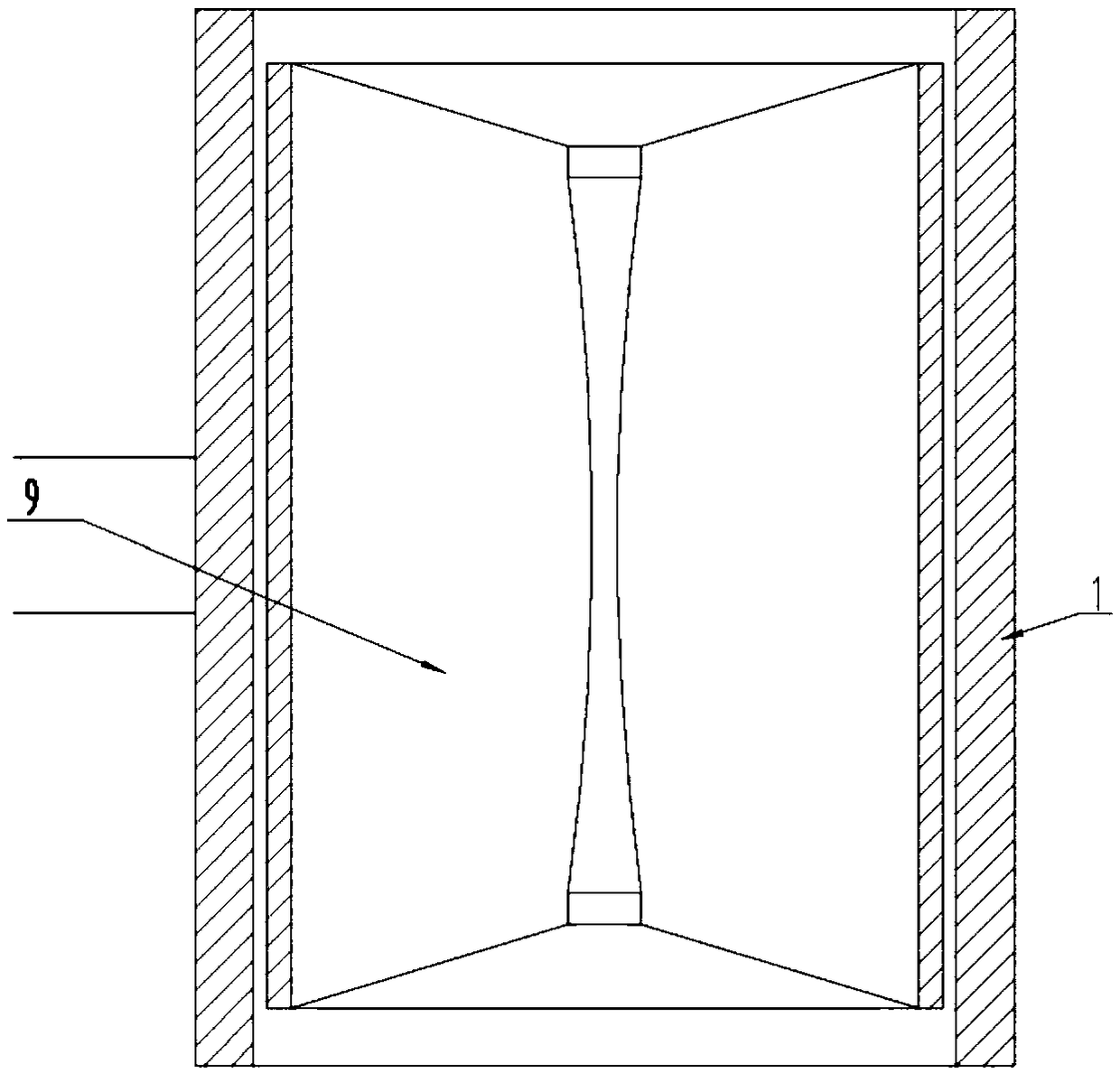

Built-in installation platform for bridge tower lightning rod and method for installing lightning rod with it

ActiveCN103321149BGuaranteed durabilityGuaranteed replaceabilityInstallation of lighting conductorsBridge structural detailsLightning rodCable stayed

The invention relates to a built-in type mounting platform for a lightning rod of a bridge tower and a method for mounting the lightning rod through the mounting platform. The bridge is a cable-stayed bridge or a suspension bridge. The mounting platform is composed of inner and outer casings of certain heights, a plain steel inner tube of the outer casing is connected with a bridge crown through a shear key, plain steel upper and lower ends of a plain steel tube of the inner casing and stainless steel outer thread steel tubes are welded together through a welding steel tube connecting plate, the stainless steel outer thread steel tubes are connected with a lightning rod base plate and a handle connecting plate, a mounting handle is welded on the handle connecting plate, and the inner and outer casings are in threaded connection. The mounting method comprises the steps of embedding the outer casing on which the shear key is welded, placing concrete, fixing the lightning rod on the lightning rod base plate, enabling the lightning rod and the inner casing to penetrate the outer casing by rotation, and stretching the lightning rod in place. By means of the mounting platform and the method, mounting and maintenance of the lightning rods of high bridge towers can be completed in the towers, out-of-tower high-altitude operations can be avoided, landscape requirements for the bridge towers are met, components outside bridge tower crowns are not added, the stability and operability are good, the mounting is simple, and the maintenance is convenient.

Owner:CHINA MAJOR BRIDGE ENERGINEERING

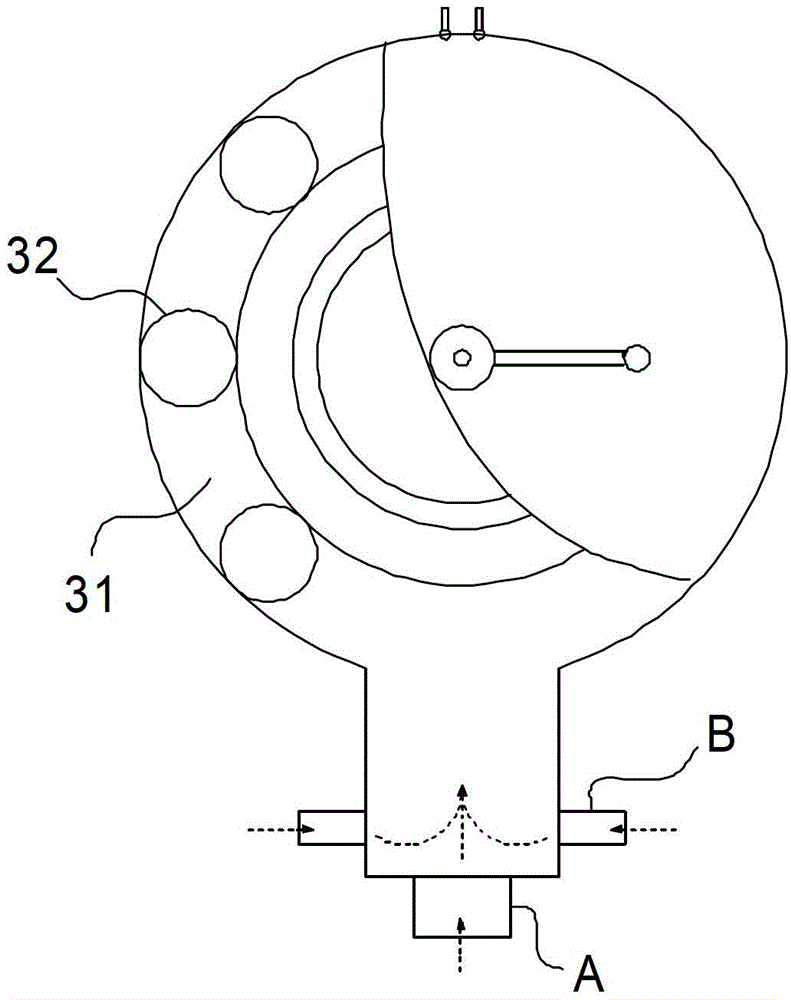

A liquid slag granulation system

ActiveCN106435063BAvoid clogging the slag seamReduce the probability of cloggingRecycling and recovery technologiesProcess efficiency improvementLiquid slagHigh pressure

Owner:BEIJING TIANSU SUNLIGHT LOW CARBON TECH

A kind of coal mining machine running wheel bearing which is convenient for maintenance

ActiveCN112412986BEasy to disassembleImprove maintainabilityBearing unit rigid supportStructural engineeringMachine

The invention discloses a traveling wheel bearing of a coal mining machine which is convenient for maintenance. The inner ring of the bearing is connected with the traveling rotating shaft in the manner of axial and radial limiting, and is also clamped with the traveling rotating shaft. In this way, The bearing can be easily disassembled to improve the ability of maintenance and replacement. The present invention also provides a convenient detachable installation mechanism for the shearer running wheel bearing which is convenient for maintenance. The detachable installation structure can effectively ensure the safety of the bearing Easy installation and replacement performance. At the same time, even if the bearing seat is damaged, it is easy to replace the bearing seat, which ensures the modular performance, effectively improves the maintenance performance of the shearer, and reduces the maintenance cost of the shearer.

Owner:LULIANG UNIV

Rail vehicles and their traction motors

ActiveCN109519479BFully Extruded Replacement ImplementationAchieve replacementShaftsBearing componentsElectric machineryTraction motor

The invention discloses a traction motor. The traction motor comprises a bearing outer oil seal, a bearing and a bearing inner oil seal, wherein the bearing outer oil seal, the bearing and the bearinginner oil seal are sequentially arranged in the axial direction, an outer oil seal oil storage chamber is formed in the bearing outer oil seal, and an inner oil seal oil storage chamber is formed inthe bearing inner oil seal. The traction motor further comprises an annular grease pocket, wherein the annular grease pocket comprises an annular groove which is coaxially formed with the bearing anda control piece which is used for driving the annular groove to move to be in contact with the bearing in the axial direction or move to be away from the bearing in the axial direction; the annular groove is arranged in the outer oil seal oil storage chamber or the inner oil seal oil storage chamber; the end, close to the bearing, of the annular groove in the axial direction is open; the end, awayfrom the bearing, of the annular groove in the axial direction is sealed, and a grease supplement opening is formed in the side, close to the annular grease pocket, of the bearing. Old grease in thebearing of the traction motor can be completely replaced during grease supplement maintenance. The invention further discloses a rail vehicle comprising the traction motor, wherein the old lubricatinggrease in the bearing of the traction motor can be completely replaced during grease supplement maintenance.

Owner:CSR ZHUZHOU ELECTRIC LOCOMOTIVE RES INST

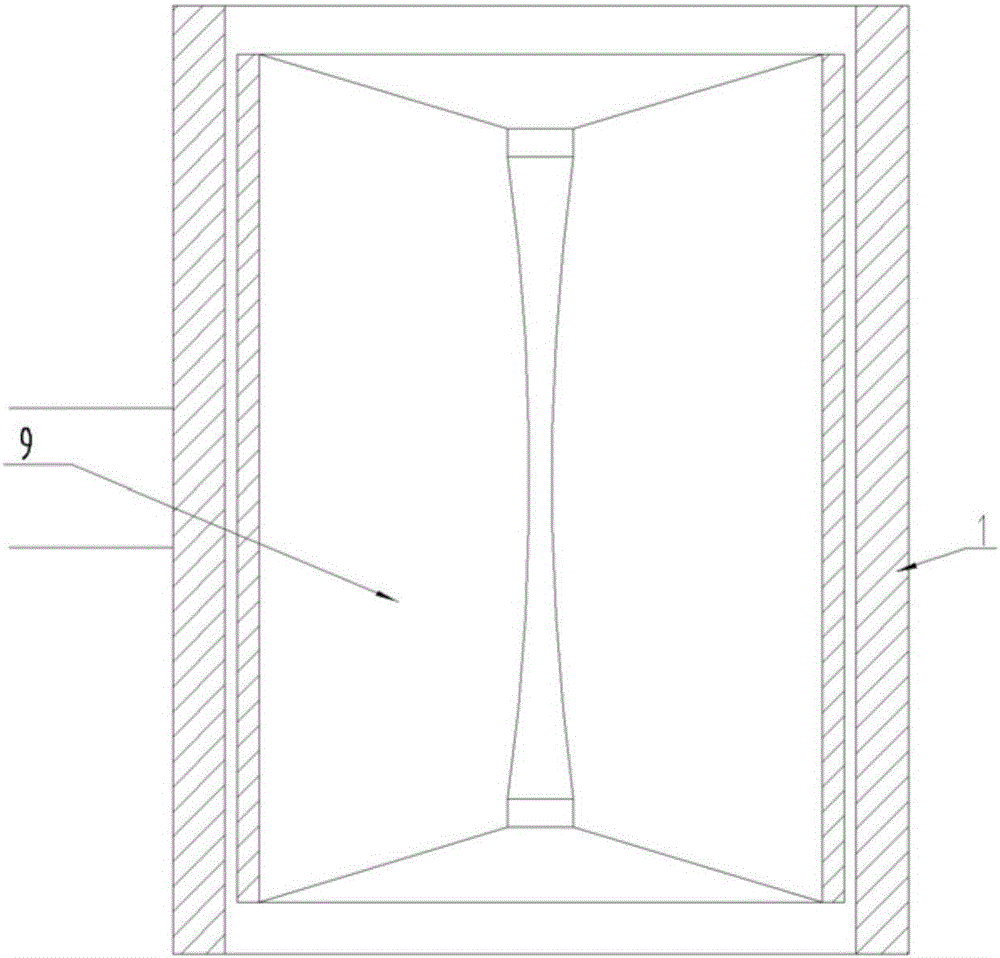

Molten furnace slag granulation system

ActiveCN106435063AAvoid clogging the slag seamReduce the probability of cloggingRecycling and recovery technologiesProcess efficiency improvementHigh pressureSystem structure

The invention relates to a molten furnace slag granulation system. The granulation system comprises a slag tank, a slag seam adjusting device, a granulating device and a slag tank lining; an opening is formed in the bottom of the slag tank; the slag seam adjusting device comprises a first roller and a second roller which are respectively arranged at the bottom of the slag tank; a gap is kept between the first roller and the second roller to form a slag seam; the slag seam is positioned under the opening in the bottom of the slag tank; the first roller and / or the second roller can move in the horizontal direction; the granulating device is arranged below the slag seam adjusting device; an ejection outlet of the granulating device is towards the lower portion of the slag seam; the granulating device is a high-pressure ejecting device; the slag tank lining is placed inside the slag tank and is matched with the slag tank in shape. The system provided by the invention is simple in structure, small in size, simple to operate during a molten slag granulation process, high in reliability, ideal in granulation effect and capable of guaranteeing sustainability of furnace slag granulation, realizing automatic cleaning during a granulation process and also greatly lowering the equipment investment and operating cost.

Owner:BEIJING TIANSU SUNLIGHT LOW CARBON TECH

An automatic replacement device for cathode plate clamping strips and expansion strips

ActiveCN111926350BQuick releaseEliminate manual disassemblyPhotography auxillary processesProcess efficiency improvementStructural engineeringCcd camera

Owner:鹰潭市智汇物联网应用研究院有限公司

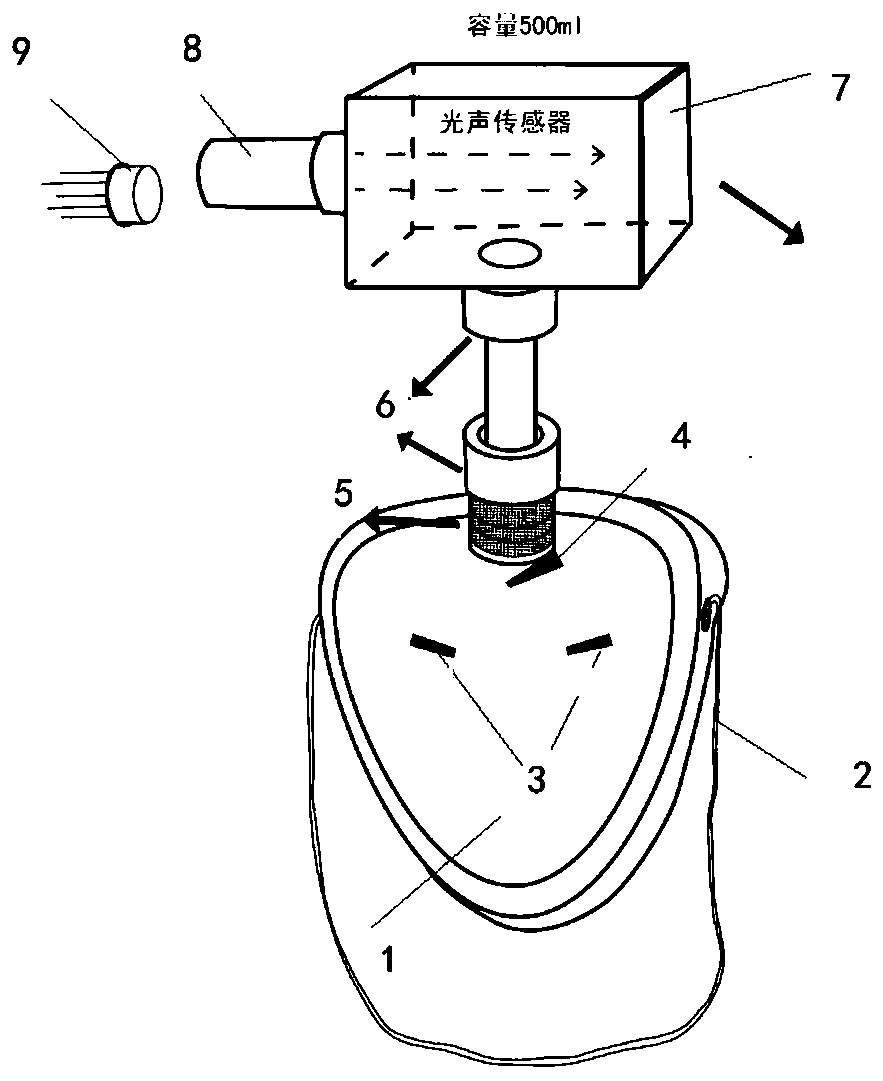

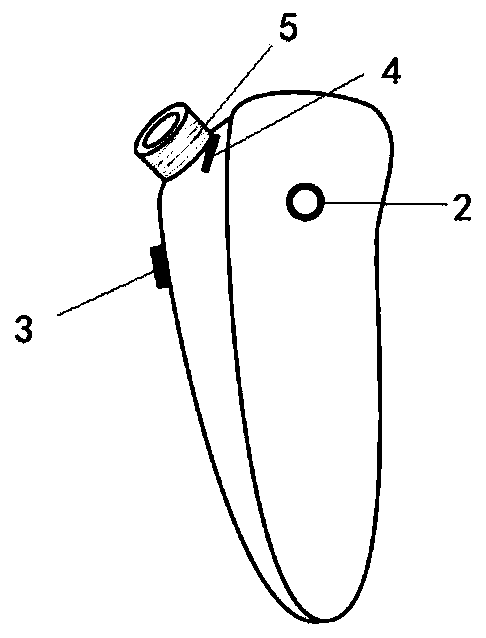

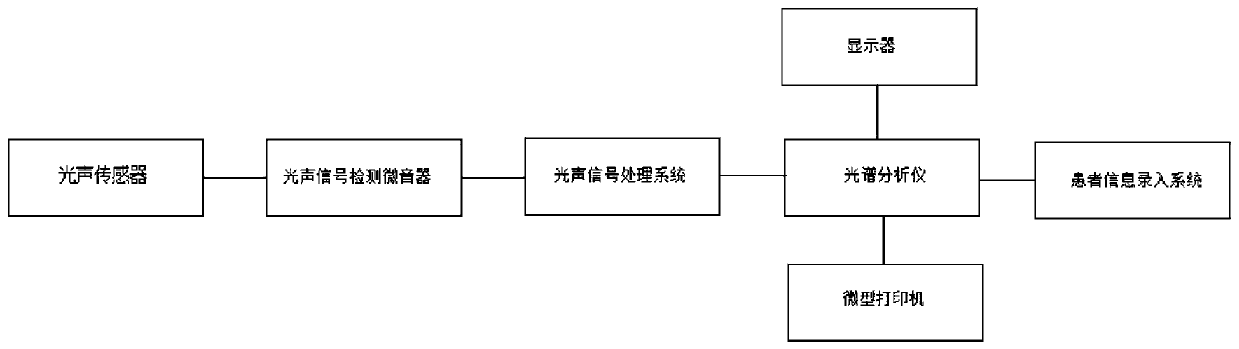

Exhalation acquisition device for liver disease patients and photo-acoustic detection method for ammonia and methyl mercaptan in exhalations

PendingCN110274883AGuarantee statusGuaranteed singularityWithdrawing sample devicesColor/spectral properties measurementsStomaMolecular sieve

The invention relates to an exhalation acquisition device for liver disease patients and a photo-acoustic detection method for ammonia and methyl mercaptan in exhalations, and belongs to the field of exhalation acquisition in order to solve the problems that a mask can be connected to or used by different exhalation acquisition devices, ensures sanitary requirements, and achieves the front-end filtering of exhalation acquisition. The exhalation acquisition device for liver disease patients includes a breathing mask and an exhalation acquisition device, wherein the breathing mask is an ear-hooked mask; the front surface of the mask has an air outlet; two air inlet valves are arranged on both sides of the air outlet; the mask is made of a polyvinyl chloride material; the air outlet is connected to a first air pipeline; the first air pipeline is provided with an one-way valve; the one-way valve is located inside a mask end; the first air pipeline is provided therein with a molecular sieve; the first air pipeline is in communication with the second air pipeline, and a joint is sealed by a spiral fixing hoop; and the second air pipeline is in communication with the exhalation acquisition device, and a joint is sealed by a spiral fixing hoop. The exhalation acquisition device for liver disease patients can be quickly replaced and ensures the sanitary requirements.

Owner:大连市第六人民医院

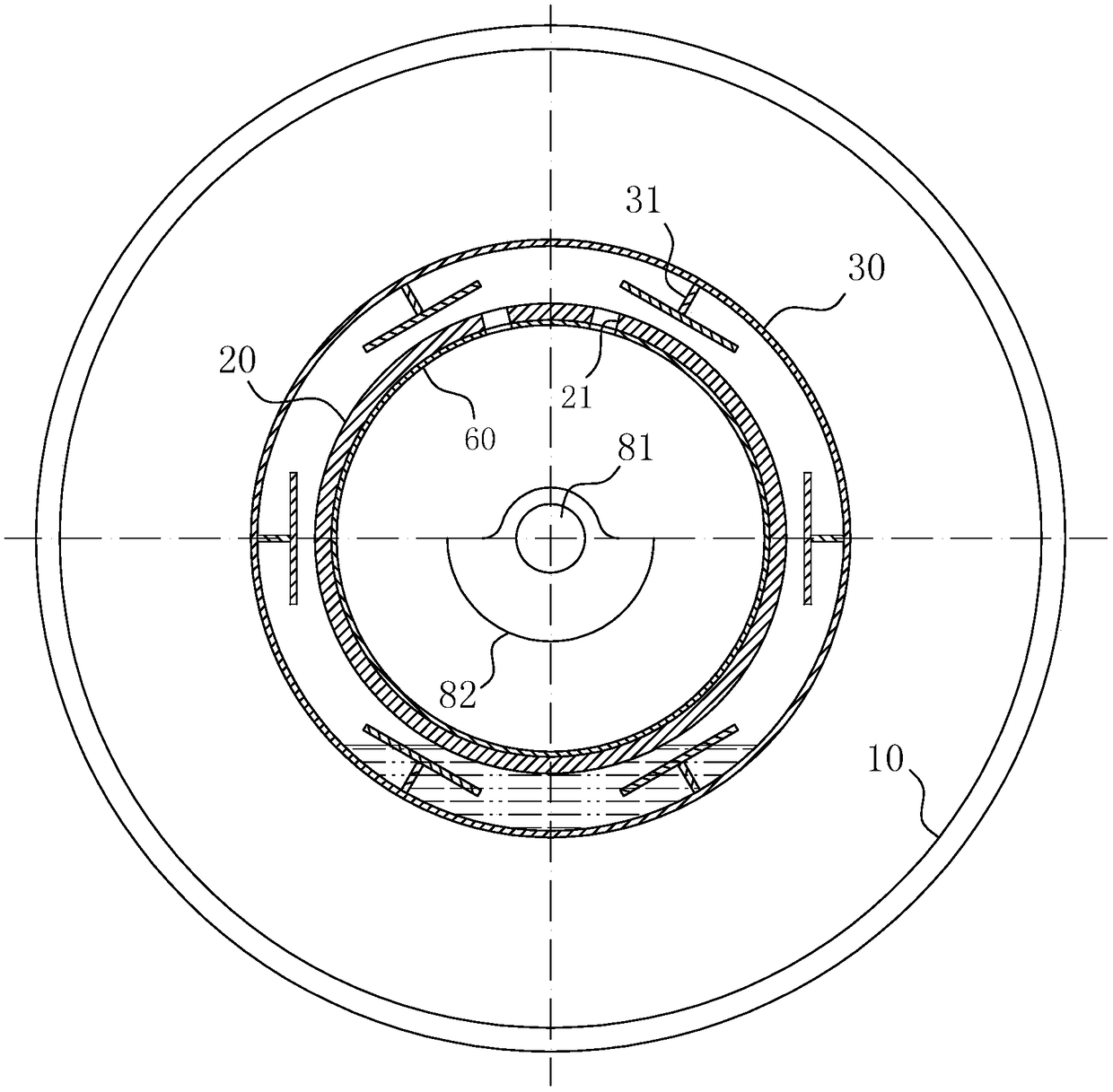

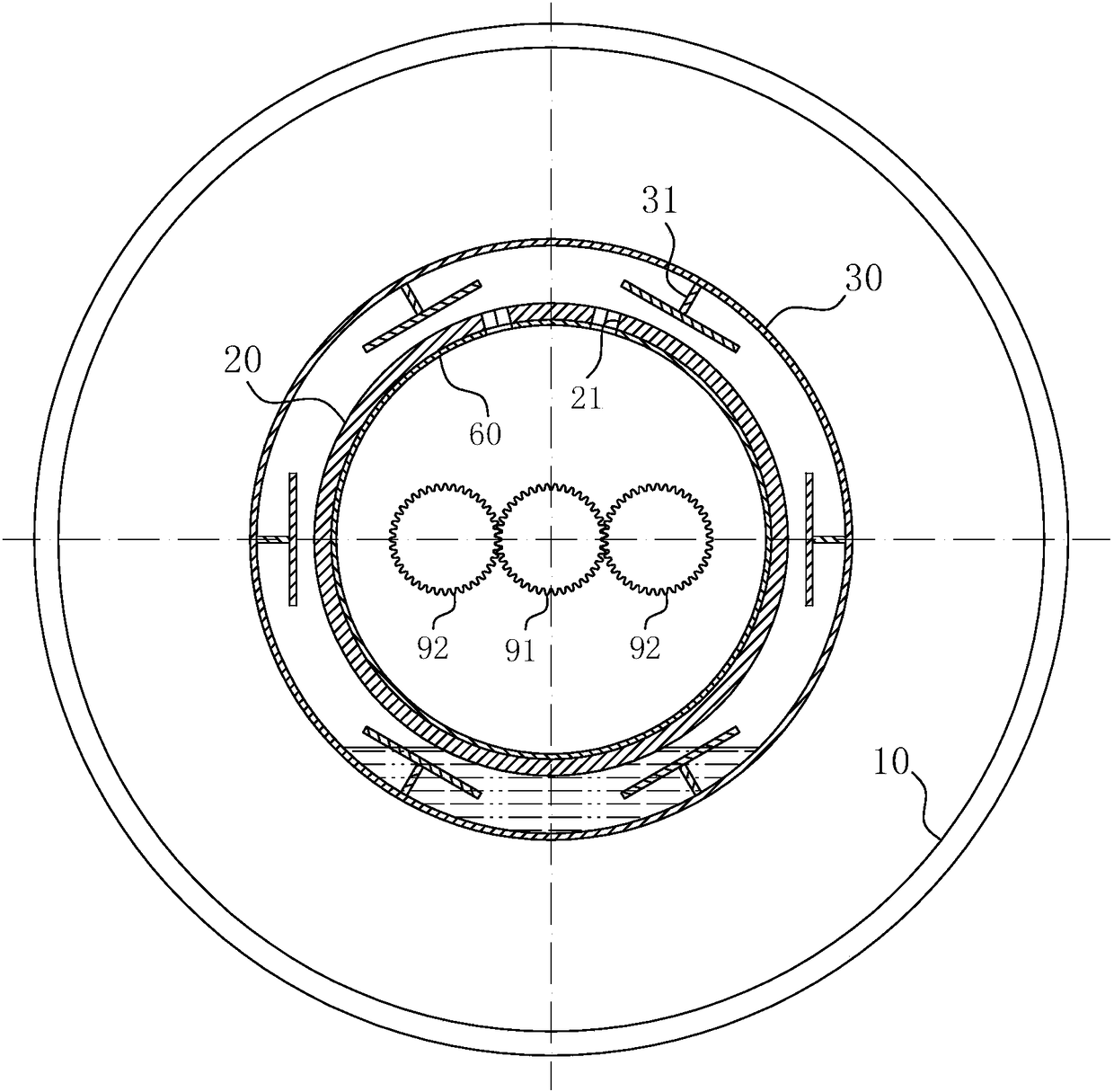

A vibration wheel with self-lubricating structure

ActiveCN106245499BEnsure adequate lubricationAdequate heat dissipationRoads maintainenceEngineeringMechanical engineering

The invention belongs to the field of road roller equipment, and specifically relates to a vibrating drum having a self-lubricating structure for use in a vibratory roller. The vibrating drum having a self-lubricating structure comprises a steel drum and an exciter barrel. A sleeve-shaped oil groove ring plate sleeves the exciter barrel. An oil inlet notch communicating a lubricating oil chamber and the cavity of the exciter barrel is formed in the outer wall of the exciter barrel. The oil inlet notch penetrates through the wall of the exciter barrel and communicates with a transmission gear and / or a bearing for supporting a set of eccentric blocks in the exciter barrel. T-form strip-shaped grooved plates are arranged on the inside annular surface of the oil groove ring plate, and the bottommost ends of the grooved plates are fixedly connected with the inside annular surface of the oil groove ring plate. The plate length direction of the grooved plates is parallel to the axis direction of the oil groove ring plate. More than two grooved plates are provided and evenly distributed at intervals in the circumferential direction of the oil groove ring plate. The vibrating drum having a self-lubricating structure allows for sufficient lubrication and heat dissipation of various kinematic members in the vibrating drum, and therefore, the use reliability and the service life of the vibrating drum are guaranteed eventually.

Owner:合肥永安绿地工程机械有限公司

Drying device and battery system and motor vehicle having the same

ActiveCN103797608BPrevent intrusionAvoid contactGas treatmentDispersed particle separationInterior spaceElectrical battery

The invention relates to a drying device (10) comprising a desiccant cartridge (18) with a desiccant (20) in order to reduce the humidity of the gas located in the interior space (34) of a housing (40) . Here, the drying device (10) has a protective chamber (32) which is placed or can be placed in the housing (40), which is liquid-tight with respect to the inner space (34) and connected gas-conductively with the inner space ( 34), the desiccant box (18) is set in the protection chamber (32). Furthermore, it relates to a battery system ( 42 ) with the drying device ( 10 ) and a motor vehicle with the battery system ( 42 ).

Owner:ROBERT BOSCH GMBH +1

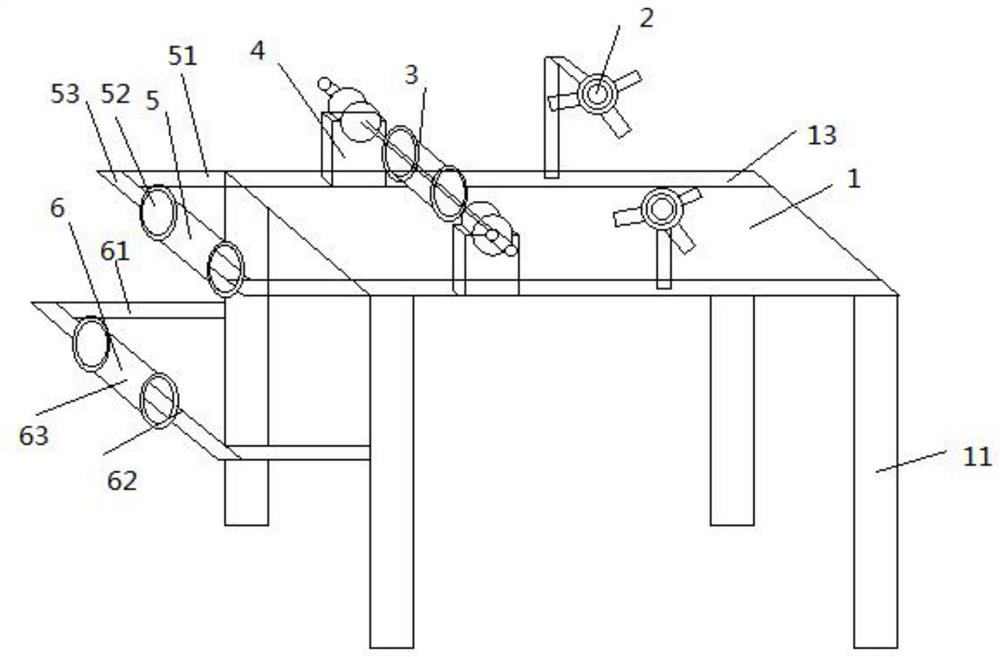

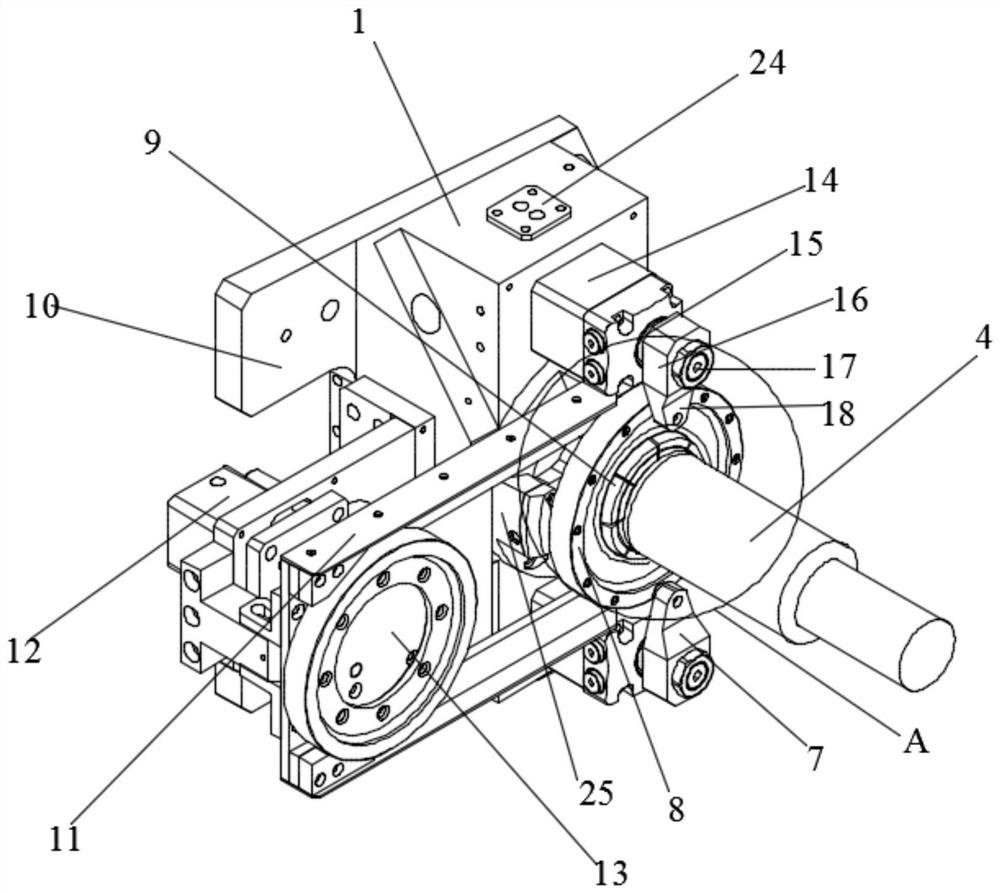

Coiler and drill jumbo with same

PendingCN109399402AGuaranteed replaceabilityFirmly connectedSlitting machinesEngineeringUltimate tensile strength

The invention discloses a coiler. The coiler comprises a fixing shaft, a roller and a guide wheel, wherein the roller is used for winding a pipeline, the guide wheel is used for winding a steel wire rope, the guide wheel and the roller are both rotatably arranged on the fixing shaft in a sleeve mode, and the guide wheel and the roller are detachably connected. According to the coiler, the guide wheel and the roller can be connected in a detachable manner and can be separated, so that the relative fixation of the guide wheel and the roller is guaranteed, and the guide wheel and the roller can rotate synchronously; the replacement performance of the guide wheel is also ensured, so that replacement with a new guide wheel is only needed after the local guide wheel is damaged, the whole rollerdoes not need to be replaced, the material cost is saved, the labor intensity is reduced, and the maintenance time is shortened; and in a preferred embodiment, the coiler is provided with a top anti-collision structure, and in another embodiment, the coiler can prevent the steel wire rope from falling off the guide wheel. The invention further discloses a drill jumbo with the coiler.

Owner:HUNAN WUXIN TUNNEL INTELLIGENT EQUIP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com