Built-in installation platform for bridge tower lightning rod and method for installing lightning rod with it

An installation platform and lightning rod technology, applied in bridges, bridge parts, bridge construction, etc., can solve the problems of inconvenient installation and maintenance of lightning rods, damage to the landscape effect of bridge towers, etc., to overcome the difficulty of installation, maintenance and replacement, convenient maintenance, Avoid the effect of working at heights

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

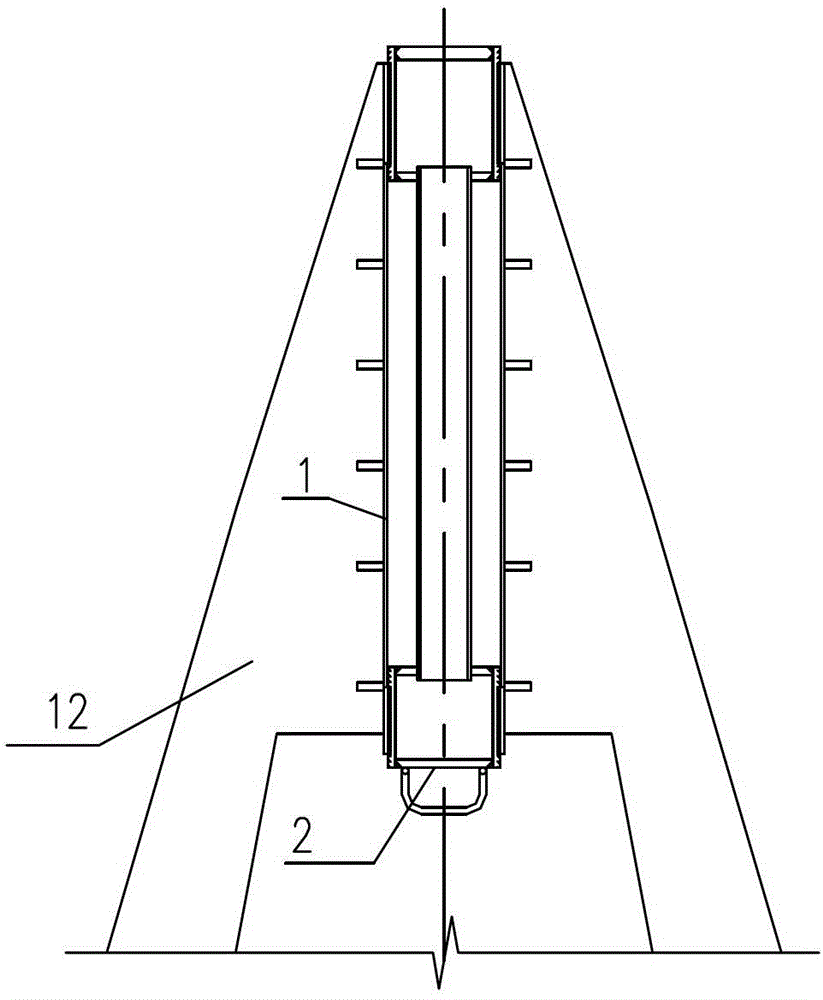

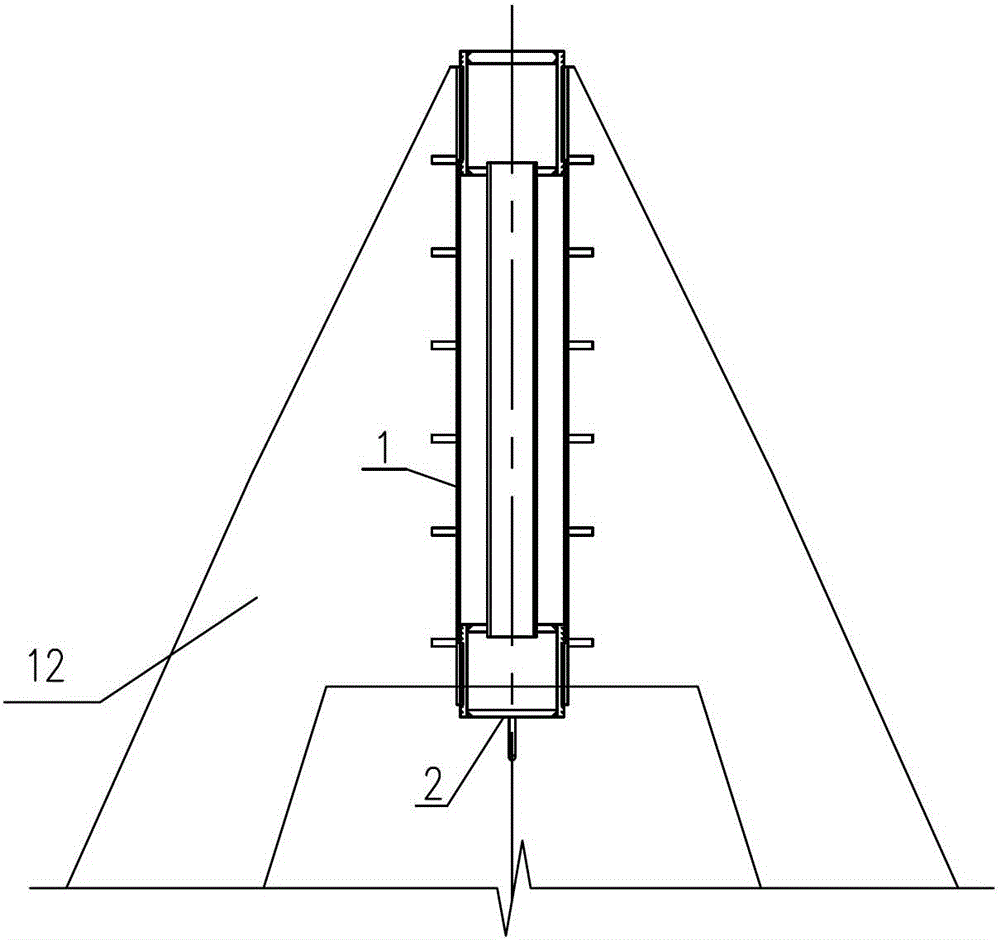

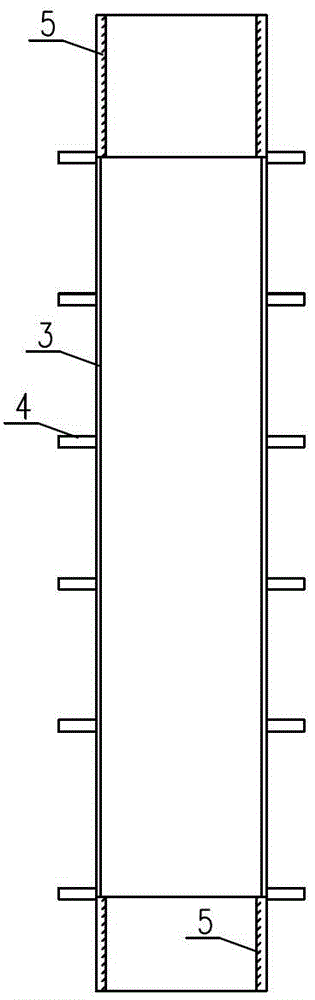

[0015] refer to Figure 1-4 , the built-in installation platform of the bridge tower lightning rod of the present invention is composed of inner and outer casings, the ordinary steel inner pipe of the outer casing 1 is connected with the bridge tower crown 12 through the shear key 4, and the upper and lower ends of the outer casing are welded with stainless steel internal thread steel pipes 5. The upper and lower ends of the ordinary steel pipe 6 of the inner casing 2 are welded together with the stainless steel external thread steel pipe 7 through the steel pipe connecting plate 9, the upper stainless steel external thread steel pipe is connected to the lightning rod base plate 8, the lower stainless steel external thread steel pipe is connected to the handle connecting plate 11, and the handle is connected The handle 10 is welded on the board; the stainless steel external thread steel pipe 7 is threadedly connected with the stainless steel internal thread steel pipe 5 .

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com