Classifying dropping-type coal slurry pretreating device

A pretreatment device, drop-type technology, applied in the direction of dissolution, mixer, chemical instruments and methods, etc., can solve the problems of different pretreatment time, contamination, flotation selectivity deterioration, etc., to reduce pretreatment time, reduce The actual input amount and the effect of slowing down the flotation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

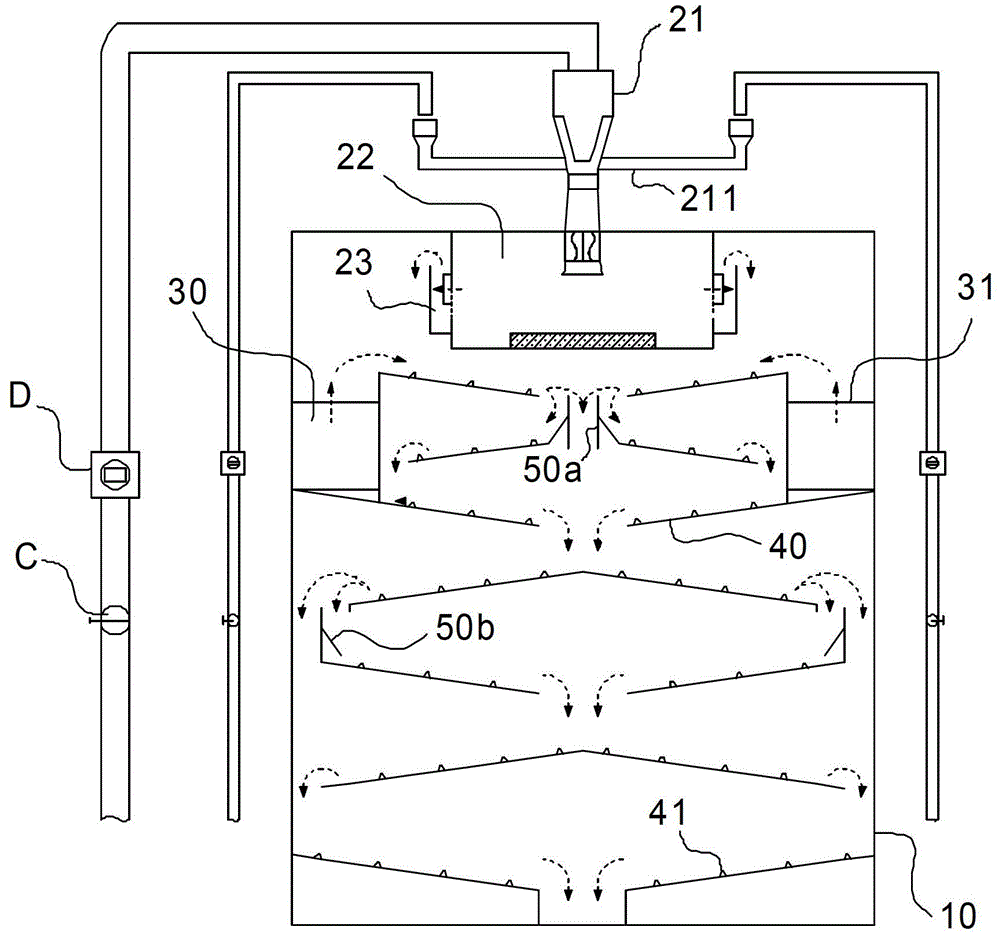

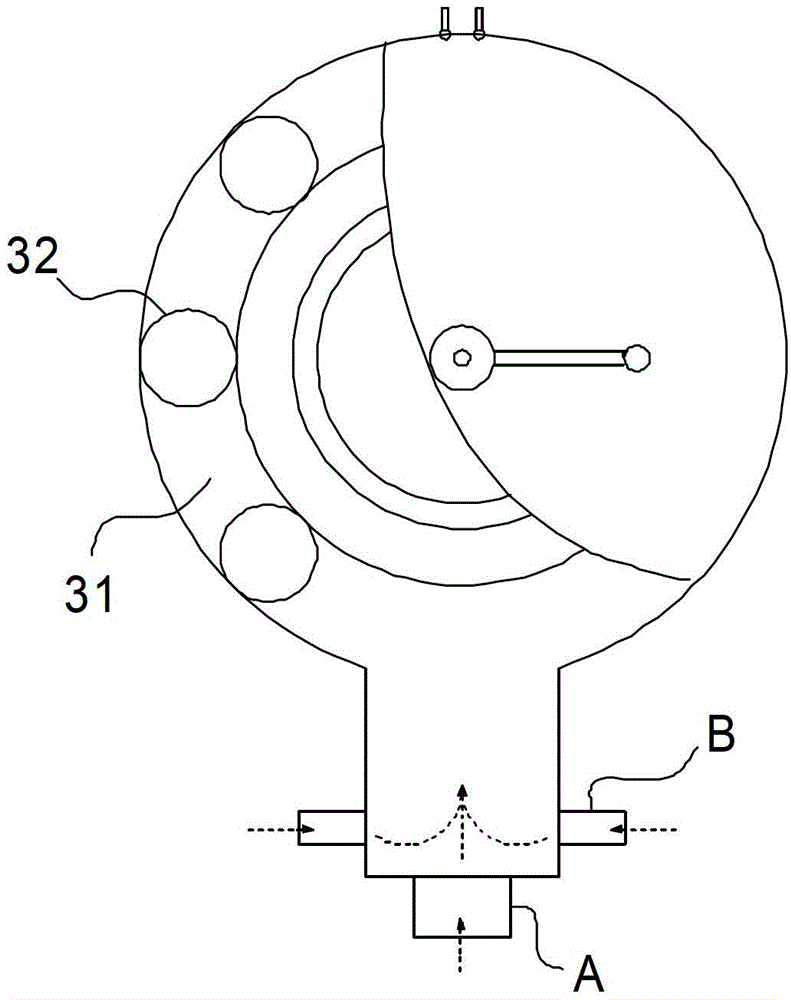

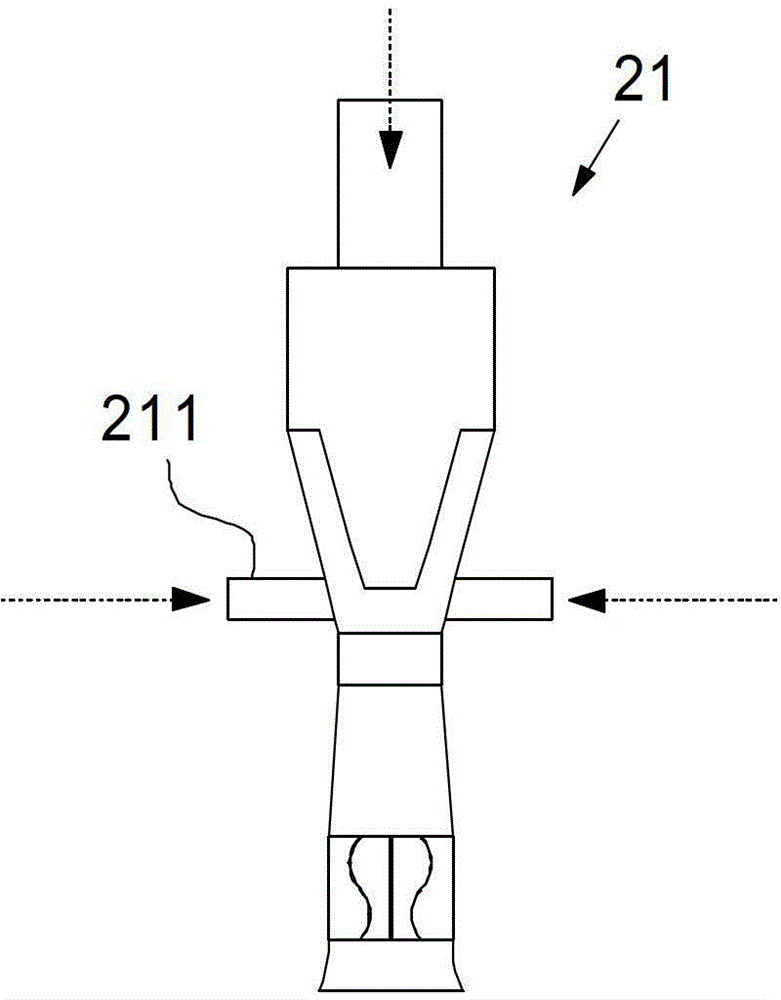

[0028] The specific components of the present invention are described as follows in conjunction with the accompanying drawings:

[0029] The present invention absorbs the advantages of the traditional atomized drop type coal slurry preprocessor, which has the advantages of central feeding and overflow on the left and right sides, and abandons the atomizing agent of the fogging plate, so that the entire working system must be in a sealed environment, but the operator cannot Observe the shortcomings of the internal working conditions of the equipment, and use the unique structure of the water jet emulsifier to emulsify the agent. On the one hand, it can achieve the effect of dispersing the emulsified agent, and on the other hand, it can open the whole working system to the operator. Easy to operate. Drawing lessons from the working advantage that each sliding plate 40 that has sill 41 in the traditional drop box 10 has different contact pretreatment time for coarse and fine part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com