A vibration wheel with self-lubricating structure

A self-lubricating, vibrating wheel technology, used in roads, buildings, road repairs, etc., can solve problems such as equipment failure, inability to release, and impact on the service life of the vibrating wheel, and achieve high lubrication and heat dissipation efficiency, sufficient lubrication, and sufficient heat dissipation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

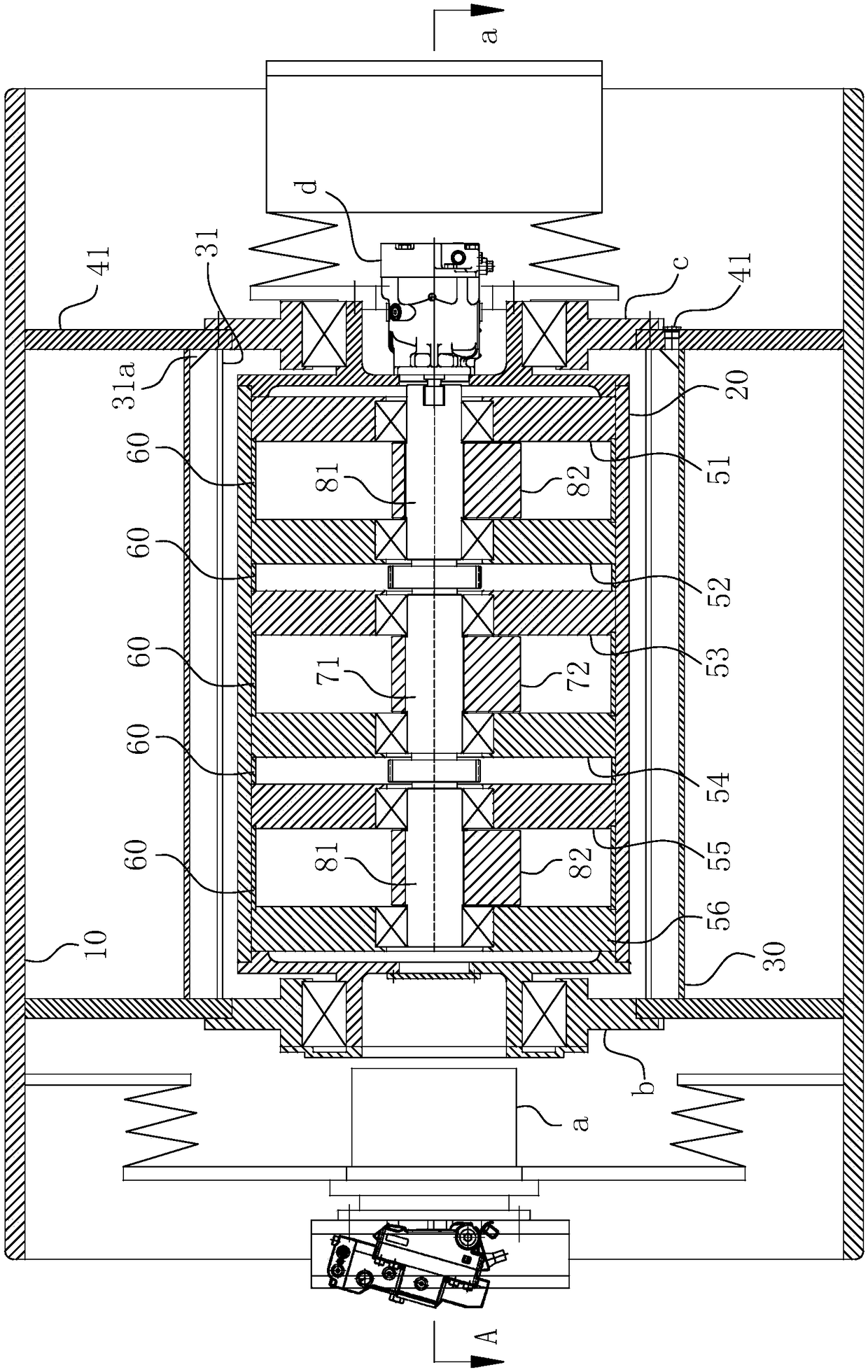

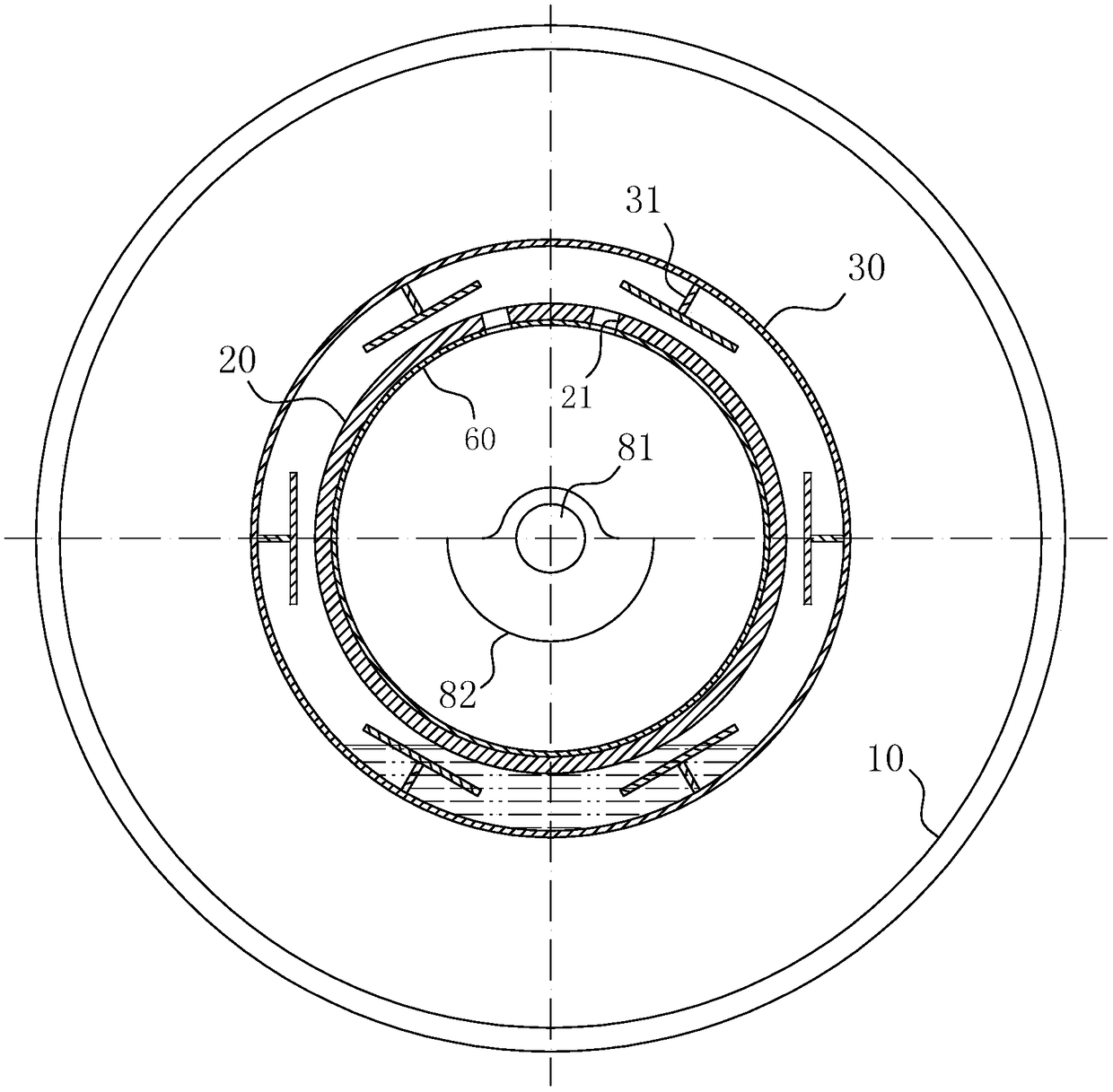

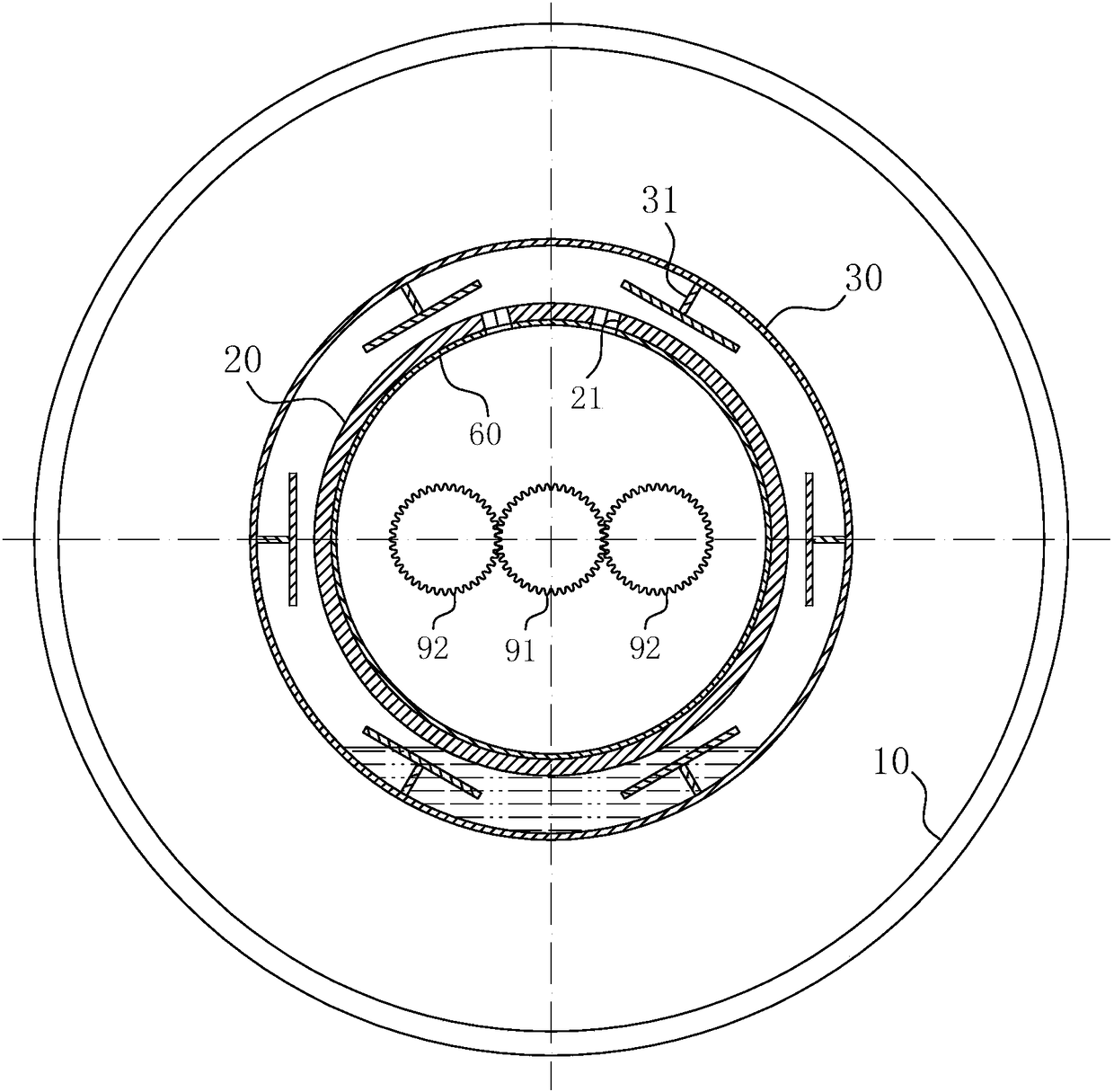

[0041] For ease of understanding, the attached Figure 1-8 Concrete structure and workflow of the present invention are described as follows:

[0042] Concrete structure of the present invention, can refer to Figure 1-6 As shown, it includes a steel wheel 10 as the outermost frame, an oil groove ring plate 30 is coaxially sleeved in the steel wheel 10 , and a vibrator cylinder 20 is coaxially sleeved in the oil groove ring plate 30 . Wherein, the vibrating wheel drive assembly a is arranged at the end of the steel wheel 10 in a suspended manner, and two ring-shaped webs 40 parallel to each other are radially arranged in the cylinder cavity of the steel wheel 10, and the webs 40 The oil groove ring plates 30 are connected to each other. The outer ring surface of the web 40 is fixedly connected to the cylinder cavity of the steel wheel 10, and the left support bearing b and the right support bearing c are clamped on the inner ring surface. An interference fixed fit is formed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com