Condenser cleaning device based on impeller turbulent flow effect

A cleaning device and turbulence device technology, applied in the direction of cleaning heat transfer devices, flushing, heat exchange equipment, etc., can solve the problems of large increase in pipeline resistance loss, easy fouling of the surface area of the bond, and easy deformation of the spiral bond, etc., to achieve The effect of increasing the convective heat transfer coefficient, saving maintenance costs, and reducing the total surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

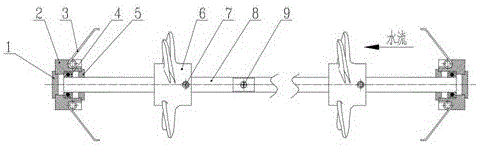

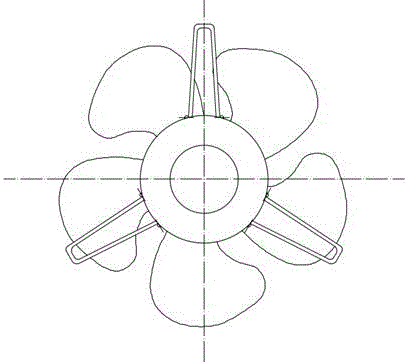

[0019] combined with figure 1 The shown condenser cleaning device based on the impeller turbulence effect is composed of an impeller strengthening turbulence device with two ends fixed on the inner wall of the condenser heat exchange tube and multiple sets of impellers 6 fixed through the shaft 8 in the middle. The impeller enhanced turbulence device includes a torsion spring tripod fixedly connected to the inner wall of the heat exchange tube, a bearing 4 connected to the torsion spring tripod and the impeller shaft 8, a shaft 8 connected to multiple groups of impellers 6, and a fastening screw 7 and Multiple groups of impellers 6 connected by shaft 8. The shaft 8 is composed of two sections, and the two sections of the shaft 8 are connected and fixed by the coupling bolt 9 . The torsion spring tripod is composed of a cylinder base 2 and a torsion spring 3. The torsion spring 3 is installed on the outer boss of the cylinder base 2 to form a triangular structure with equal in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com