Steel tube concrete truss composite beam with detachable bridge deck and construction method

A technology of steel tube concrete and steel tube truss, which is applied in the direction of bridges, truss bridges, bridge forms, etc., which can solve the problems of long installation period of steel tube concrete trusses and restrictions on the installation site, so as to broaden the scope of application of the site, shorten the construction period, and achieve good practical significance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

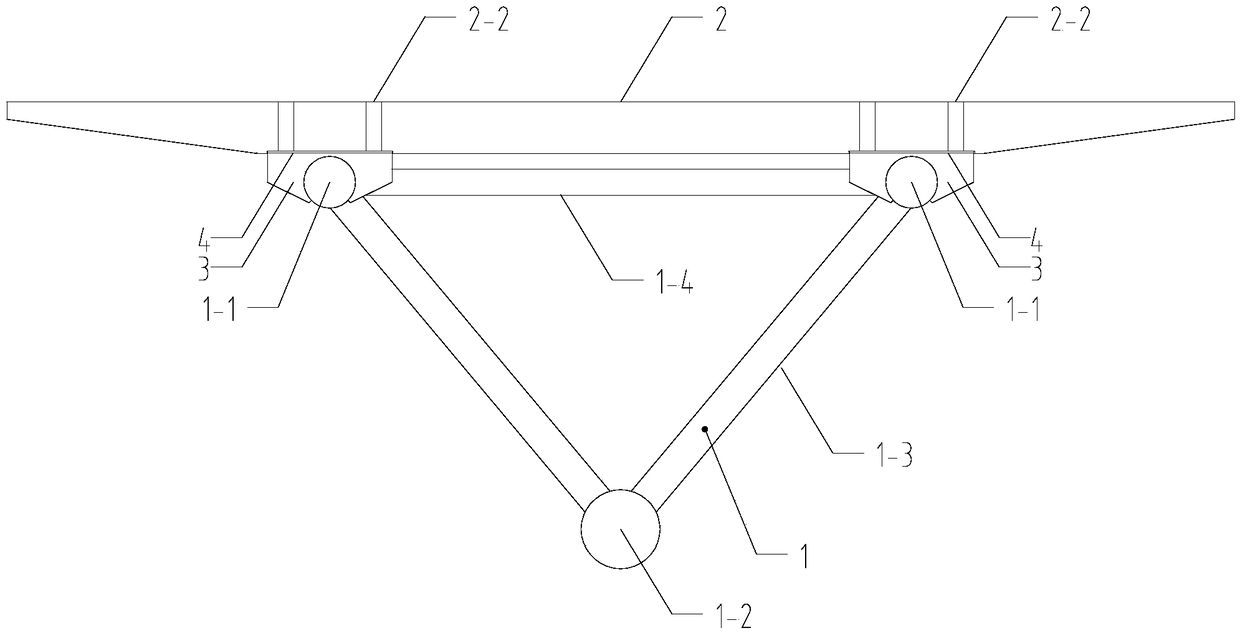

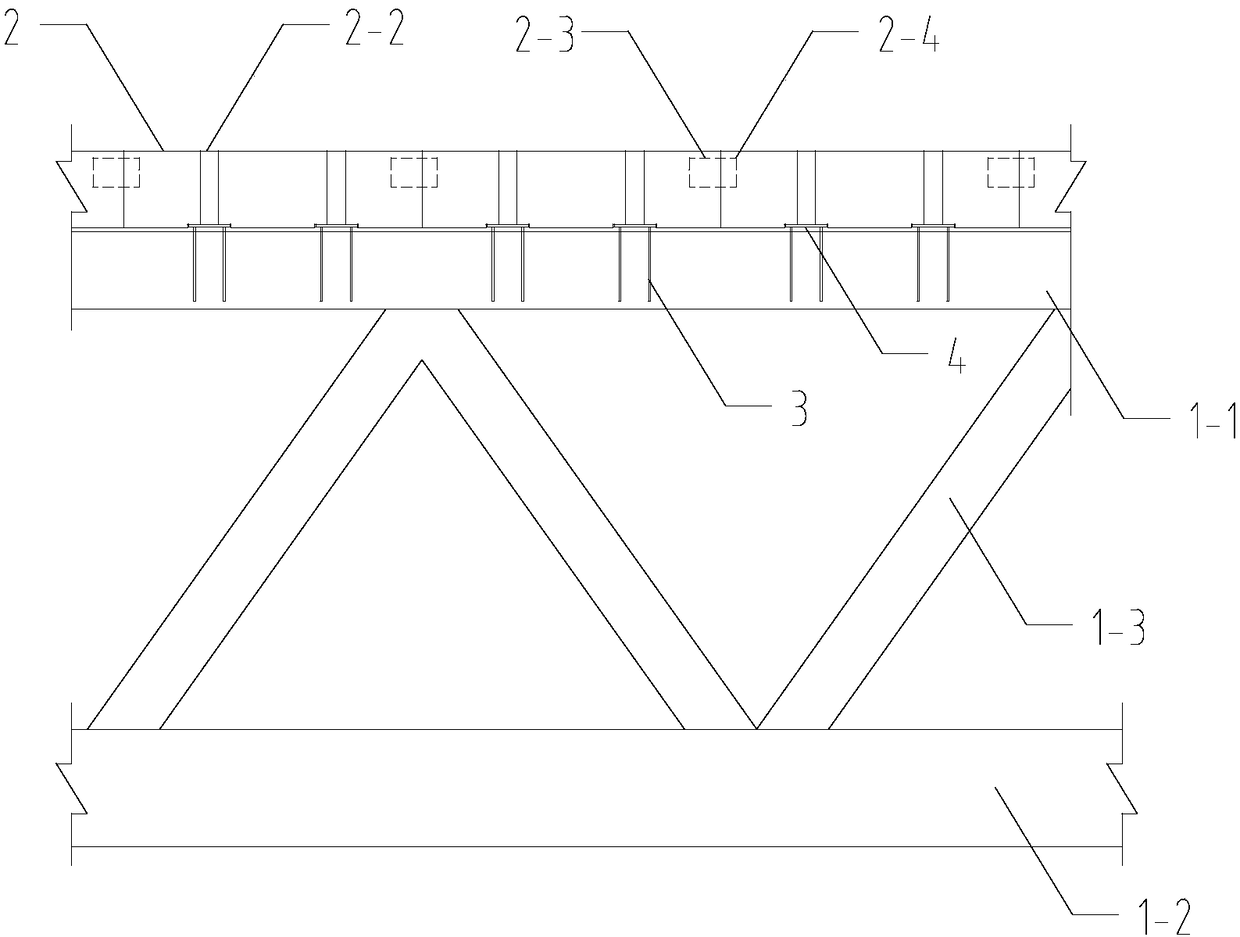

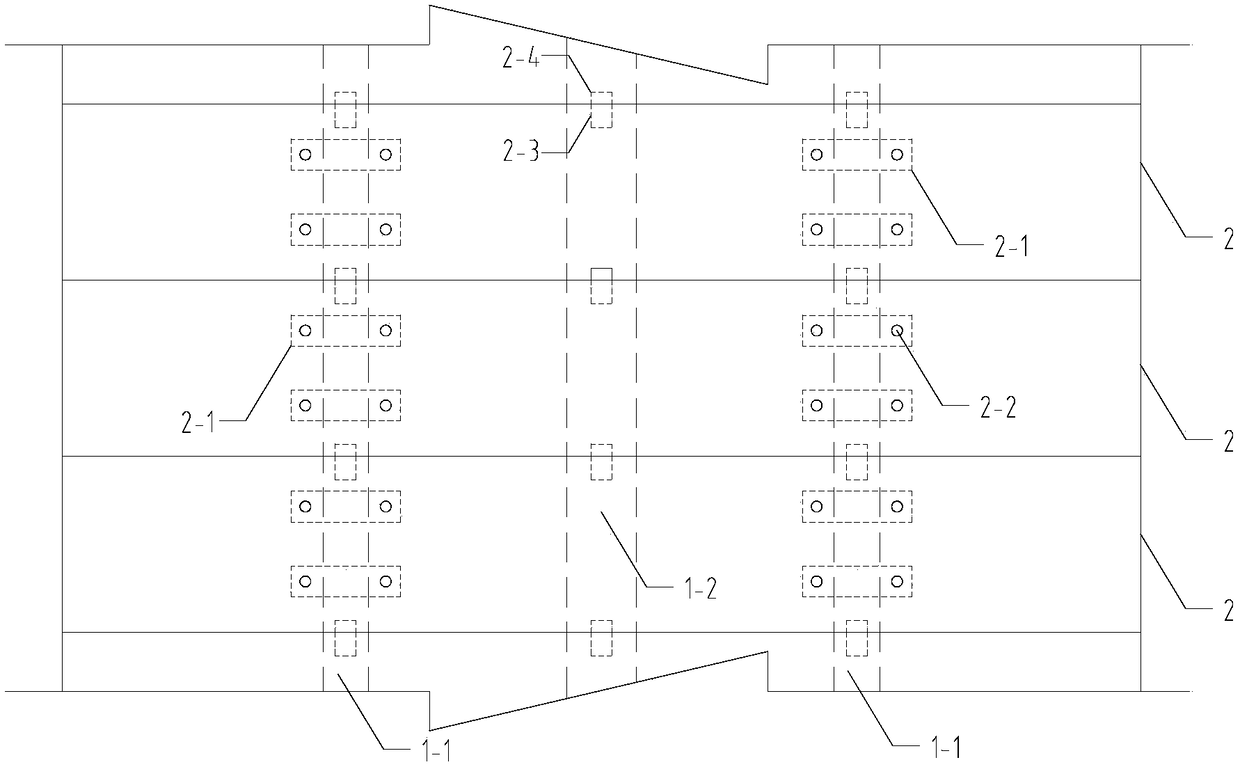

[0037] see Figure 1-Figure 14 , a steel tube concrete truss composite beam with a replaceable bridge deck, comprising a steel tube truss 1 . The structure of steel pipe truss 1 is well known to those skilled in the construction field. It is a structure formed by connecting steel pipes with hinges at both ends. It is a plane or space structure with triangular units composed of straight rods, which includes two upper chords 1-1, a lower chord 1-2, several abdominal pipes 1-3 and upper flat pipe 1-4, the upper chord 1-1 and the lower chord 1-2 are parallel, and the lower chord 1-3 is connected to the upper chord 1-1 and the lower string pipe 1-2, and the upper flat pipe 1-4 is connected between the upper string pipes 1-1.

[0038] The axial d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com