Energy dissipation body structure of elevated single-column station

A shock-absorbing body and energy-dissipating technology, applied in special structures, earthquake-proof, building components, etc., can solve the problems of difficult maintenance and replacement, affecting the seismic performance of structural systems, occupying the usable area of the structure, etc., so as to improve safety. Redundancy, improved torsional effect, reduced repair cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

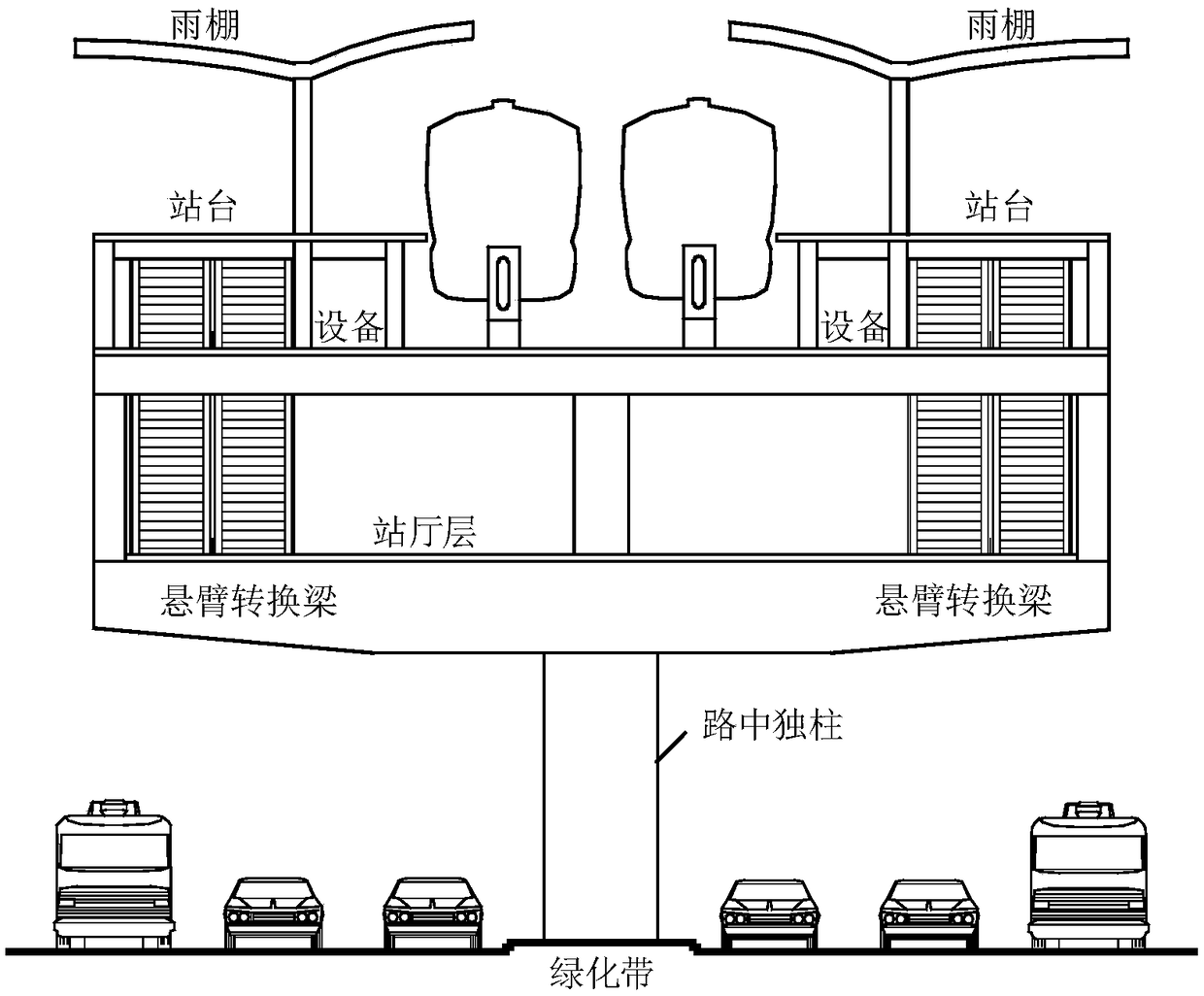

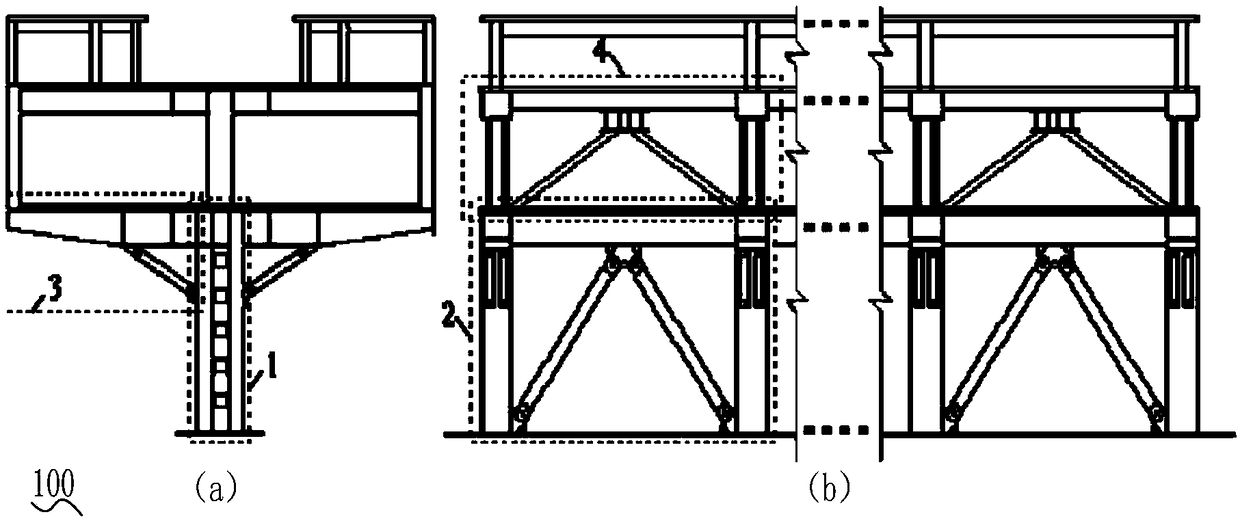

[0048] Such as figure 2 As shown, it is used for the energy dissipation and shock absorption system of the elevated single-pillar station. The system mainly includes four types of energy dissipation and shock absorption substructures, 1-4 are energy dissipation pier columns, bottom buckling-resistant bracing frame, and axillary buckling-resistant bracing cantilever conversion Beams and second-story shear-coupled eccentrically braced frames. In the elevated single-pillar station, according to the different seismic fortification intensity and fortification goals of the site where the project is located, one or more energy-dissipating and shock-absorbing substructures can be selected as required to form the energy-dissipating and shock-absorbing system of the station, and for a certain An arrangement of energy-dissipating and shock-absorbing substructures can be used individually or repeatedly in one or more places of the structure according to requirements. In these substructu...

Embodiment 2

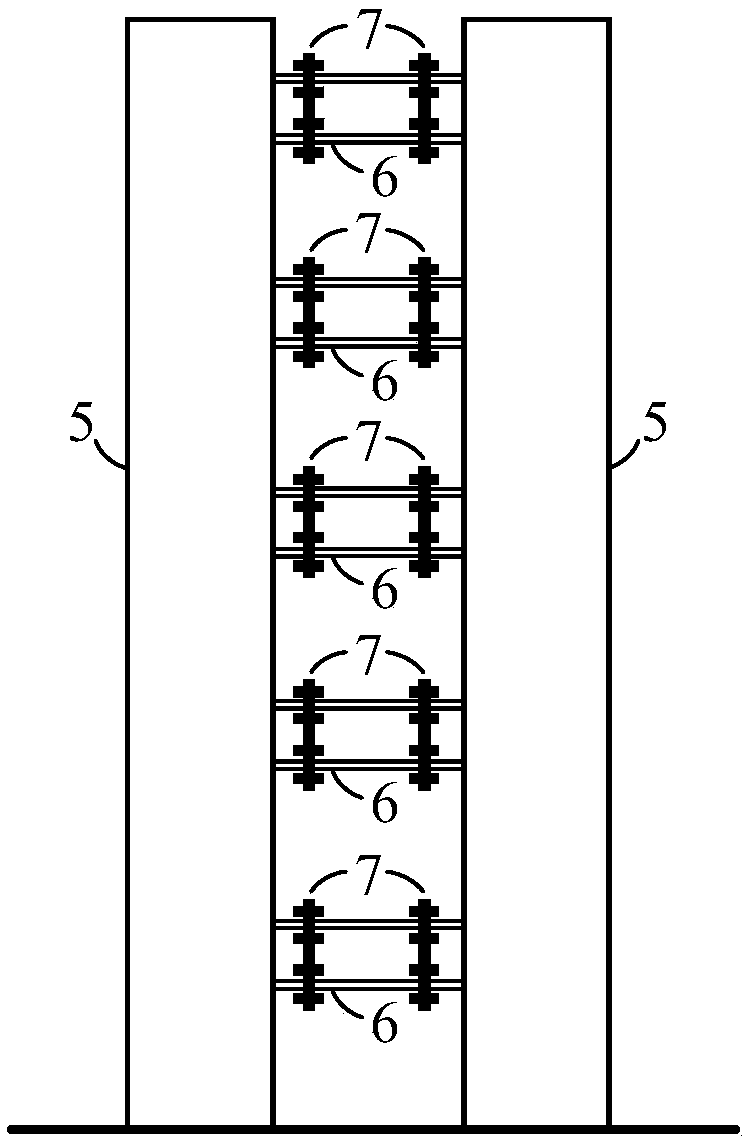

[0050] Such as image 3 As shown, the energy dissipation and shock absorption system used for the elevated single-column station, for the energy-dissipating pier column structure it contains. The energy-dissipating pier column is mainly used to improve the seismic performance of the structure in the transverse bridge direction. The energy-dissipating pier column is composed of two tightly arranged steel tube concrete column limbs, and is connected by a low yield point shear coupling beam in the middle. The corbels are welded on the inner side of the steel tube concrete column limbs during processing, and the shear coupling beam passes through such as Figure 7 Connection nodes shown are connected to steel corbels. Compared with the original single-column pier, the width and cross-sectional area of the energy-dissipating pier column are increased, so the stiffness and bearing capacity in the elastic state are increased, which can effectively control the lateral deformation o...

Embodiment 3

[0052] Such as Figure 4 As shown in , the energy dissipation and shock absorption system used for the elevated single-column station is for the underlying buckling-resistant bracing frame substructure contained in it. The buckling-resistant bracing frame is mainly used to improve the seismic performance of the structure along the bridge to the ground floor. The buckling-resistant bracing frame is composed of the column limbs of the pier columns on the ground floor and the longitudinal main beam of the first floor, and the buckling-resistant bracing connection is set in the middle. After the frame construction is completed, the hinged joints are welded at the parts connected to the anti-buckling supports. One end of the hinged joints is welded to the frame. When passing through, attention should be paid to the use of reinforcement plates for reinforcement, while the other end of the hinged joints is still designed as an end plate connection. form, thereby employing buckling-re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com