Open-end spinning rotor

A technology of free end and rotor, which is applied in the direction of free end spinning machine, spinning machine, continuous winding spinning machine, etc., and can solve the problem of unreliable torque transmission.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

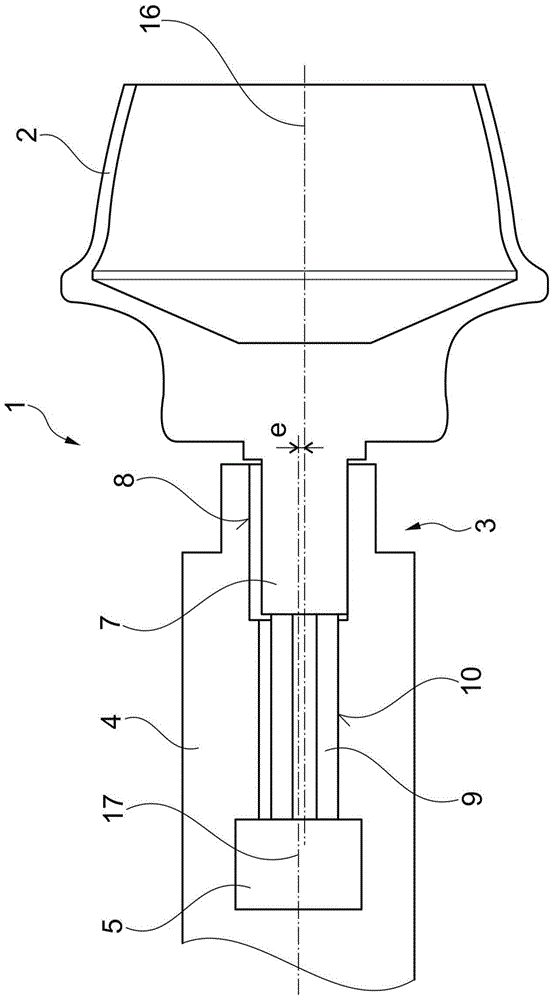

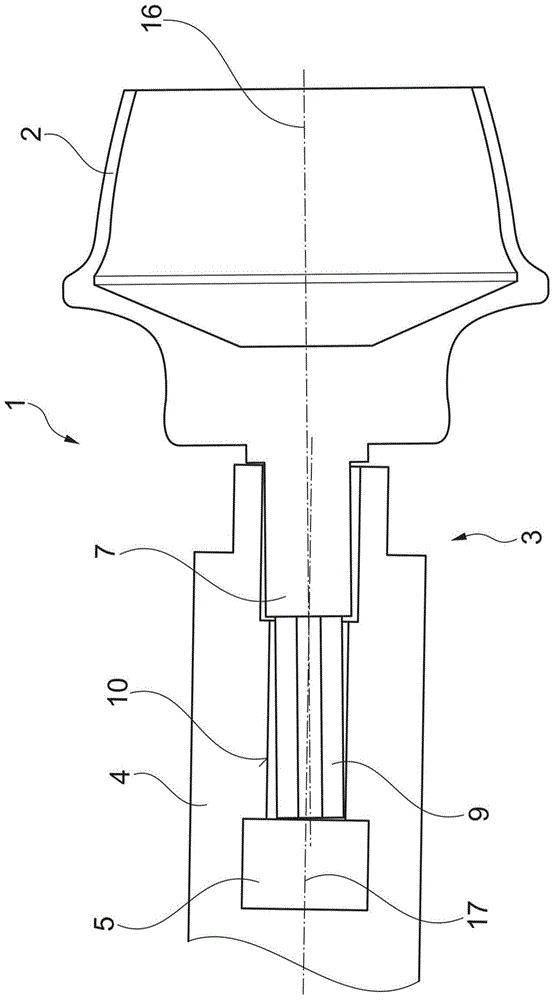

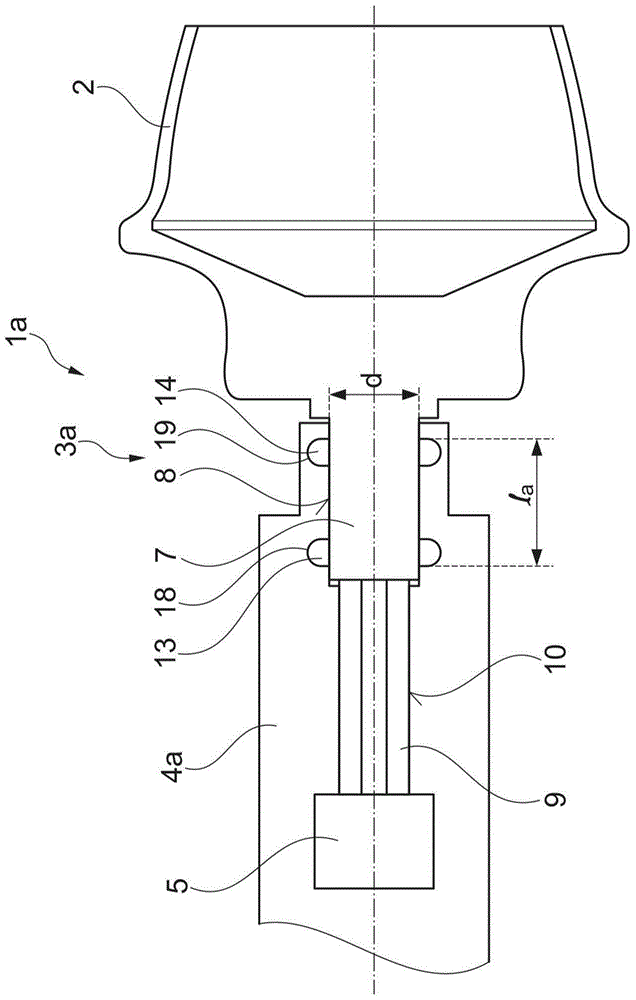

[0028] figure 1 and figure 2 A spinning rotor 1 is shown with a connecting device 3 as known in the prior art, for example from the previously cited document EP 1156 142 B1. The problem improved by the invention will be explained with the aid of these two diagrams. figure 1 and figure 2 Both show the same spinning rotor 1, so the spinning rotor 1 will only be described once in the following. The spinning rotor 1 comprises a rotor cup 2 and a rotor shaft 4 interconnected by a connecting device 3 . The rotor shaft 4 is mounted to a suitable device (not shown) and connected to a drive (not shown). The drive rotates the rotor shaft 4 and thus the spinning rotor 1 . The rotor cup 2 has appendages. This appendage is subdivided into a cylindrical guide appendage 7 and a form-fitting locking element 9 . In the present illustration, the form-fitting locking element 9 is configured as an outer polygon. The rotor shaft 4 has a cylindrical bore portion 8 corresponding to the cyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com