A wire surface spraying device

A technology of surface spraying and wire rods, applied in spraying devices, electrostatic spraying devices, liquid spraying devices, etc., can solve problems such as coating layer performance discount, structural damage, and wire quality cannot be guaranteed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] An embodiment of the present invention:

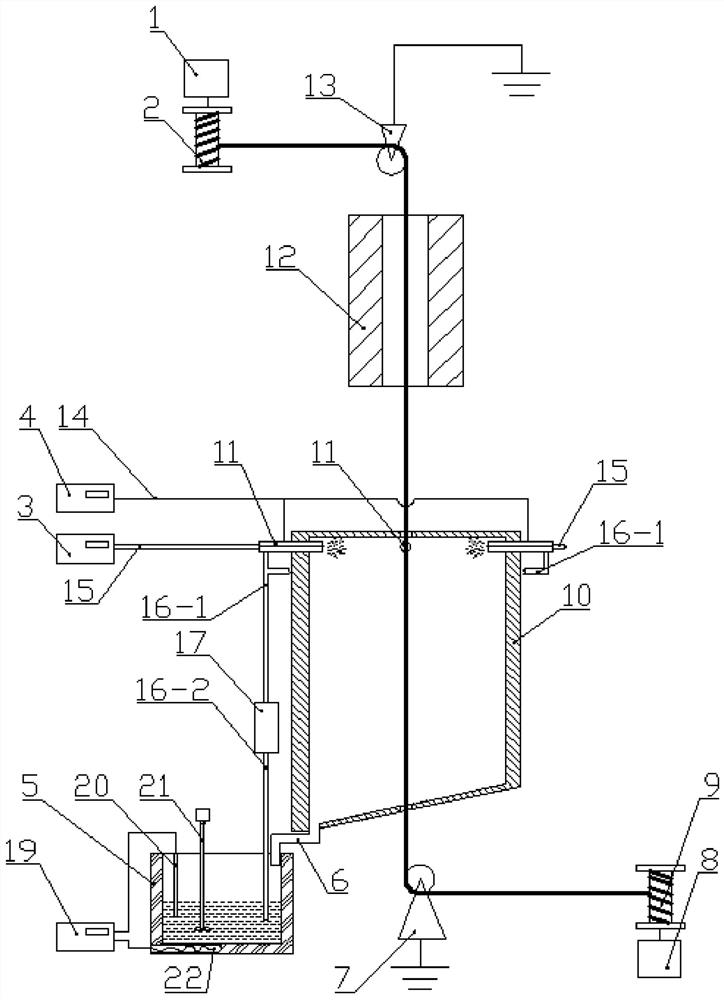

[0021] see figure 1 , a wire surface spraying device, including a pay-off mechanism 8, a wire take-up mechanism 1, and a slurry box 5. A spray tank 10 and a drying oven 12 are arranged between the pay-off mechanism 8 and the wire take-up mechanism 1. The said The wire pay-off mechanism 8 is located below the spray tank 10, a first guide wheel 7 is provided between the pay-off mechanism 8 and the spray tank 10, the drying oven 12 is located above the spray tank 10, and the wire take-up mechanism 1 is located in the drying oven Above 12, a second guide wheel 13 is provided between the wire take-up mechanism 1 and the drying oven 12. The first guide wheel 7 and the second guide wheel 13 are grounded, so that the wire passing through the guide wheel forms a positive pole, and the first guide wheel 7. The second guide wheel 13 can also control the wire on a vertical line, and avoid the situation that the slurry on the surface of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com