Method for reducing glass splashed balls during metal shell fabrication

A technology of metal casing and glass, which is applied in the manufacture of metal casings to reduce glass splashing. It can solve the problems that the glass blank is not very dense, cannot maintain its shape, and falls on the surface of the mold or product, so as to reduce the phenomenon of splashing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

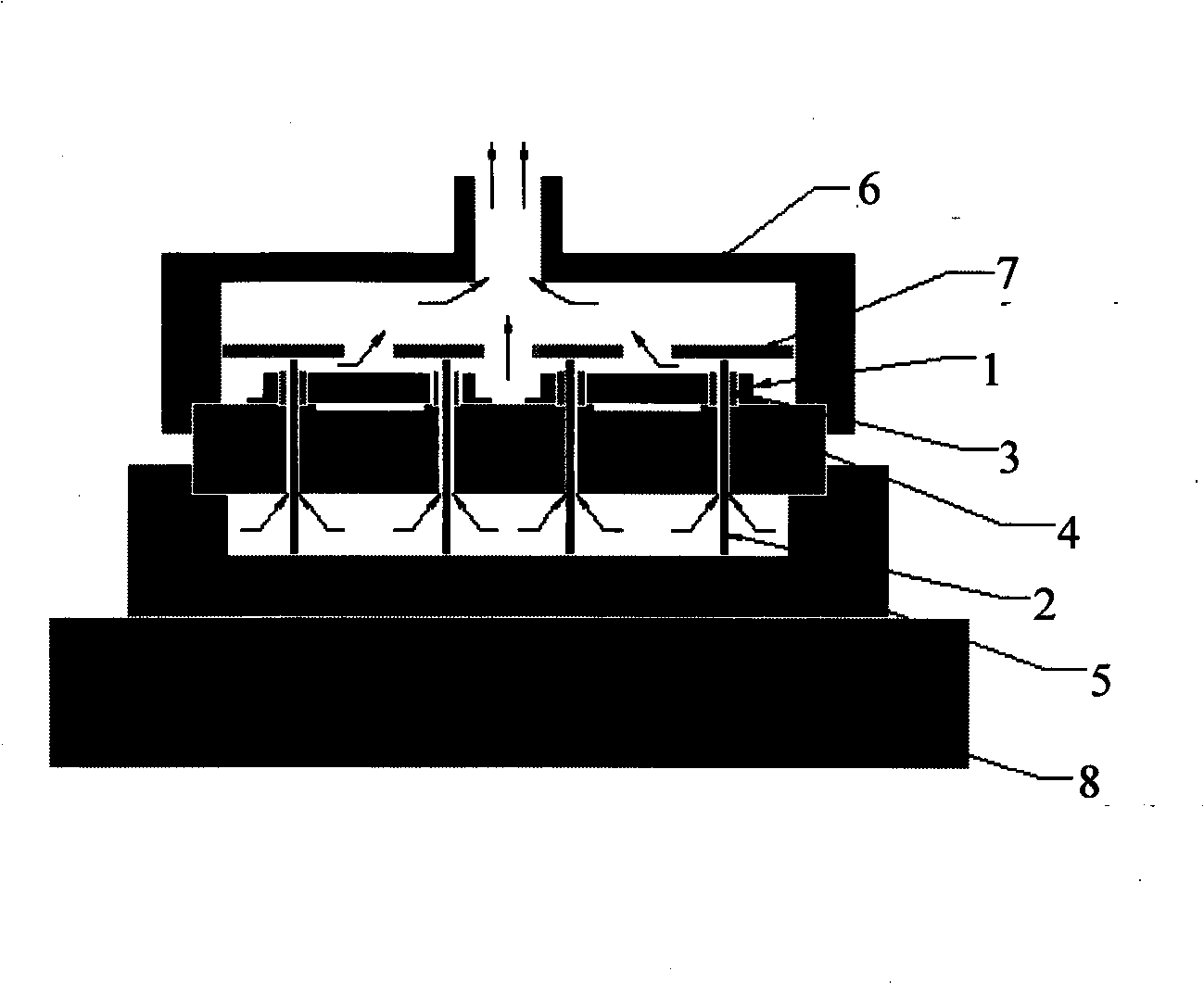

[0017] As shown in the figure, the present invention discloses a method for reducing glass splashing in the manufacture of a metal casing, which includes the following steps:

[0018] Step 1. Mount the metal shell shell 1, the lead wire 2 and the glass insulator 3 in the graphite mold 4, and set the support plate 5 under the graphite mold.

[0019] Step 2: Cover the suction device 6 on the graphite mold. The inner cavity of the suction device is provided with a porous plate 7 and the joints between the suction device and the graphite mold are sealed.

[0020] Step 3: Place the assembled suction device, graphite mold and the supporting plate 5 under it on the vibrating table 8.

[0021] Step 4. Start the air extractor and the vibrating machine to extract air while vibrating the mold, so that the glass flakes adhering to the metal shell 1, the lead wire 2 and the glass insulator 3 will pass through the airflow hole on the suction device 6 along with the airflow. Smoke away.

[0022]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com