Recovery processing method of aluminum profile surface oxidation treatment tank liquor

A surface oxidation treatment and recovery treatment technology, applied in chemical instruments and methods, anodic oxidation, sulfur trioxide/sulfuric acid, etc., can solve the problems of high production input equipment and raw material costs, inability to obtain purity, and impact on the environment, etc., to achieve large Environmental and economic benefits, maximized use of sulfuric acid, and simple treatment steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] In one of the embodiments, the preparation method of the settling agent comprises the following steps:

[0045] Sodium hydroxide, carboxymethyl cellulose and titanium dioxide are mixed and ball-milled to obtain mixture A;

[0046] Add the auxiliary base material to the mixture A, heat to 50°C-85°C under the condition of stirring at 350r / min-1200r / min, and keep stirring for 25min-50min to obtain mixture B;

[0047] The mixture B is fully swollen in deionized water, then placed in an acidic solution, and stirred at 45°C-65°C for 15min-30min to obtain a porous mixture B;

[0048]After the porous mixture B is washed with deionization, it is placed in deionized water and shaken for 2h-4h, and after the steps of suction filtration and drying, a sedimentation agent is obtained. The sedimentation agent prepared by the present invention has a porous structure, and sodium hydroxide, carboxymethyl cellulose, and titanium dioxide can form a synergistic system to further adsorb alu...

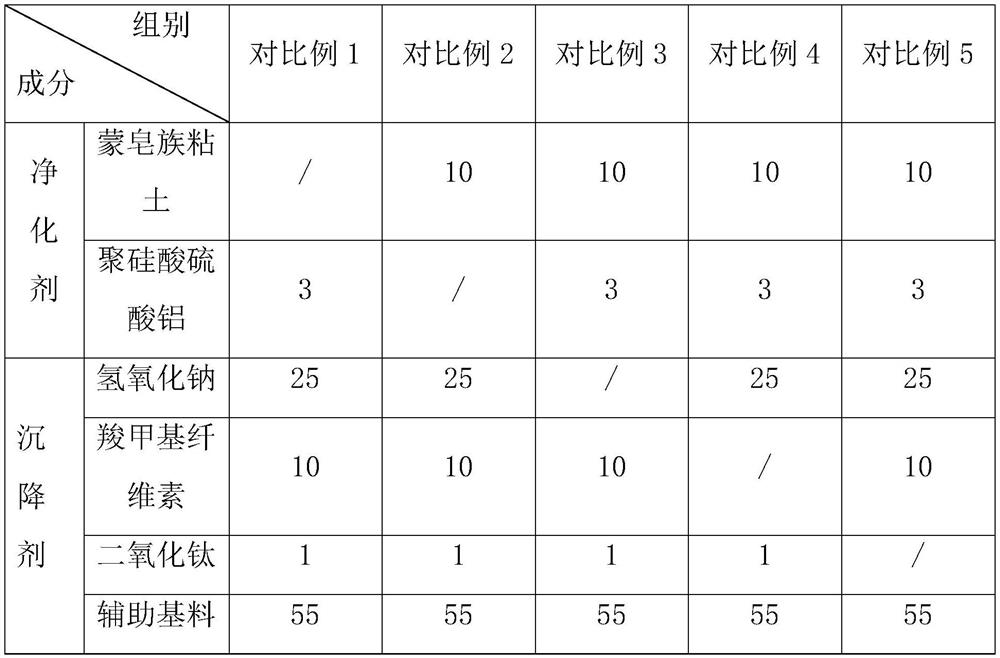

Embodiment 1

[0068] 10g of smectite clay and 3g of polysilicate aluminum sulfate are mixed to obtain a purifying agent;

[0069] 25g of sodium hydroxide, 10g of carboxymethyl cellulose and 1g of titanium dioxide were mixed and ball-milled to obtain a mixture A with a particle size of 100 μm; 55g of auxiliary base material was added to the mixture A, and heated to 85°C, and continuously stirred for 50 minutes to obtain a mixture B; the mixture B was fully swollen in deionized water, then placed in a sulfuric acid solution with a concentration of 15%, and stirred at 45°C for 15 minutes to obtain a porous mixture B; After the porous mixture B is washed with deionization, it is then placed in deionized water and shaken for 2 hours, and after the steps of suction filtration and drying, a sedimentation agent is obtained for subsequent use;

[0070] Pass the bath solution after oxidation surface treatment of aluminum profiles with a sulfuric acid concentration of 131.5g / L and an aluminum ion conc...

Embodiment 2

[0077] A method for recovering and treating bath liquid for oxidation treatment on the surface of aluminum profiles, said method comprising the following steps:

[0078] 15g of smectite clay and 1g of polysilicate aluminum sulfate are mixed to obtain a purifying agent;

[0079] 15g sodium hydroxide, 10g carboxymethyl cellulose and 5g titanium dioxide were mixed and ball milled to obtain a mixture A with a particle size of 80 μm; 30g of auxiliary base material was added to the mixture A, and heated to 50°C, and continuously stirred for 25 minutes to obtain a mixture B; the mixture B was fully swelled in deionized water, then placed in a 15% acetic acid solution, and stirred at 45°C for 30 minutes to obtain a porous mixture B; After the porous mixture B is washed with deionization, it is then placed in deionized water and shaken for 2 hours, and after the steps of suction filtration and drying, a sedimentation agent is obtained for subsequent use;

[0080] Pass the bath solutio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com