Method for producing two- or three-dimensionally shaped flat conductors from metal

A technology of three-dimensional forming and metal manufacturing, which is applied in the direction of contact manufacturing, metal processing equipment, root rod/rod/wire/strip conductor, etc., and can solve problems such as long takt time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Method used

Image

Examples

Embodiment Construction

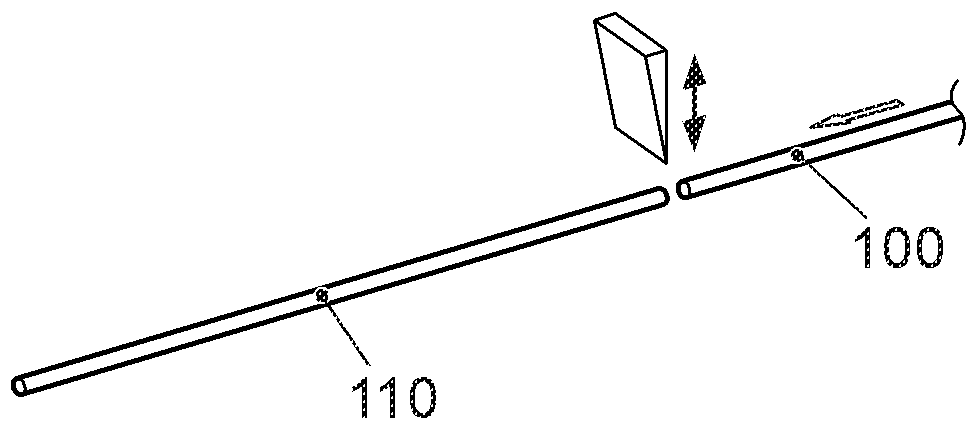

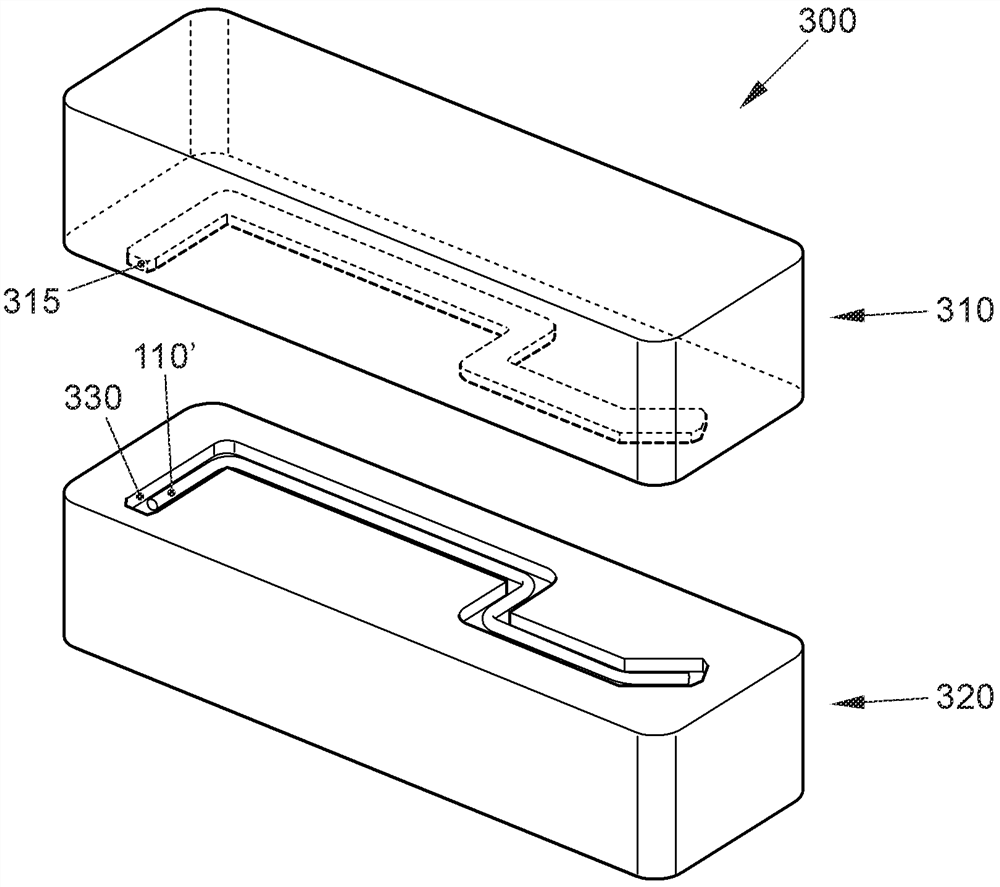

[0045] exist figure 1 The figure illustrates the production of the wire part 110 by cutting the wire semi-finished product 100 , which, for example, is removed from the coil. The straight wire member 110 has a circular cross-section. Next, the wire member 110 is as in figure 2 It is formed in the die-bending tool 200 as illustrated in Fig. Here, the wire part 110 is bent differently at a plurality of bending points, so that a plurality of curved sections (bending points) and straight sections lying in a plane are produced. The die bending tool 200 has an upper die or tool 210 and a lower die or tool 220 which are configured with a die cavity 230 adapted to the profile of the wire. The bending is achieved by the sinking of the upper die 210 . The lower mold 220 is constructed in sections and has an intermediate section 225 which secures the wire part 110 against the upper mold 210 before bending.

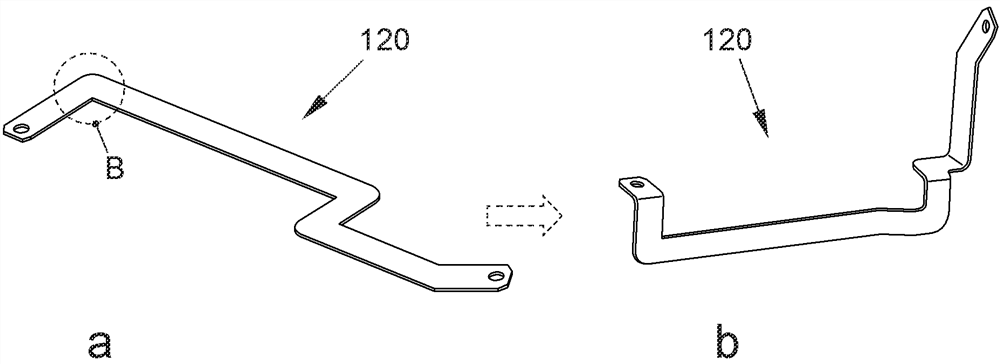

[0046] After the wire is bent, the bent wire piece 110' is flattened in th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com