Microprism die manufacturing method reducing joint dark band

A technology of patchwork dark zone and production method, which is applied in the direction of manufacturing tools, welding equipment, laser welding equipment, etc., can solve the problems of reducing mold patchwork dark zone, large invalid reflective area, etc., to reduce the width of non-reflective dark zone, Wide range of application and the effect of reducing the width of dark bands

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

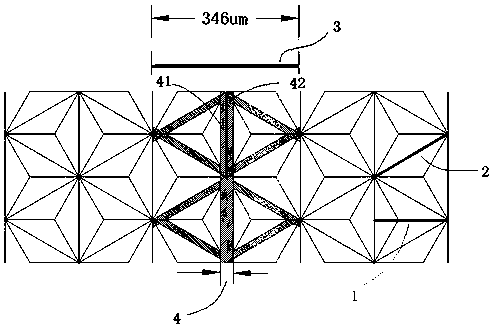

[0050] A method for making a microprism mold that reduces the dark band of the seam, comprising the steps of:

[0051] (1) see Image 6 , select a microprism initial template 5, and place it under a microscope, adjust the magnification of the microscope until the microprism initial template 5 can be clearly observed, observe the direction of the microprism initial template 5 pyramid arrays and the fine V grooves of the microprism In the direction, mark the direction and distance m of the tool machining path, and measure the thickness d of the initial template 5 of the microprism to be processed (d refers to the distance from the bottom of the micro V groove to the non-pyramid surface), and measure the micro V groove Groove angle a.

[0052] (2) Select the tool used for finishing cutting. The tool is a V-shaped knife with a V-shaped cross section, and install the tool on the cutting path running device.

[0053] (3) see Figure 5 , the microprism initial template 5 to be pro...

Embodiment 2

[0060] A method for making a microprism mold that reduces the dark band of the seam, comprising the steps of:

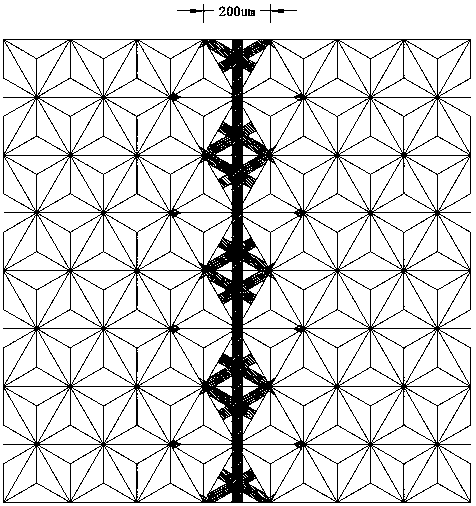

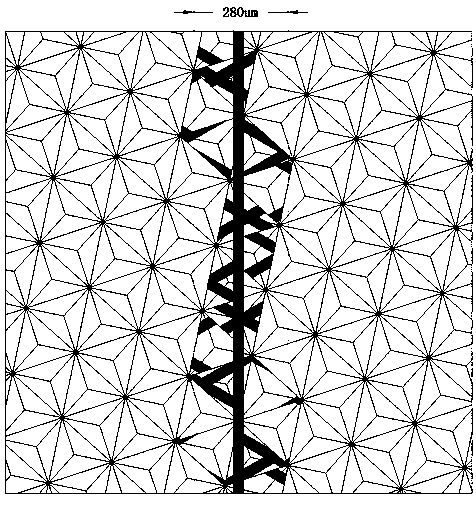

[0061] (1) Select an initial microprism template 5, place it under a microscope, adjust the magnification of the microscope until the initial microprism template 5 can be clearly observed, observe the direction of the pyramid array of the initial microprism template 5 and the microprism fine V The direction of the groove, mark the direction and distance m of the tool machining path, and measure the thickness d of the initial template 5 of the microprism to be processed (d refers to the distance from the bottom of the micro-V groove to the non-pyramid surface), and measure the micro-prism V-groove angle a, unit pyramid size 1, unit pyramid ineffective reflective area size L1, see Figure 11 shown.

[0062] (2) Select the tool used for finishing cutting. The tool is a V-shaped knife with a V-shaped cross section and is installed on the cutting path running device.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com