Inspection robot

A technology for inspection robots and fuselages, applied in the field of inspection robots, can solve the problems that inspection robots cannot flexibly adapt to different inspection tasks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0046] Further, as another specific implementation of the inspection robot provided in this application, it also includes modules such as PM2.5 (fine particulate matter) detection, temperature and humidity detection, and RFID (radio frequency identification) to detect multiple types of data , and display and operate through the above-mentioned touch screen 43 .

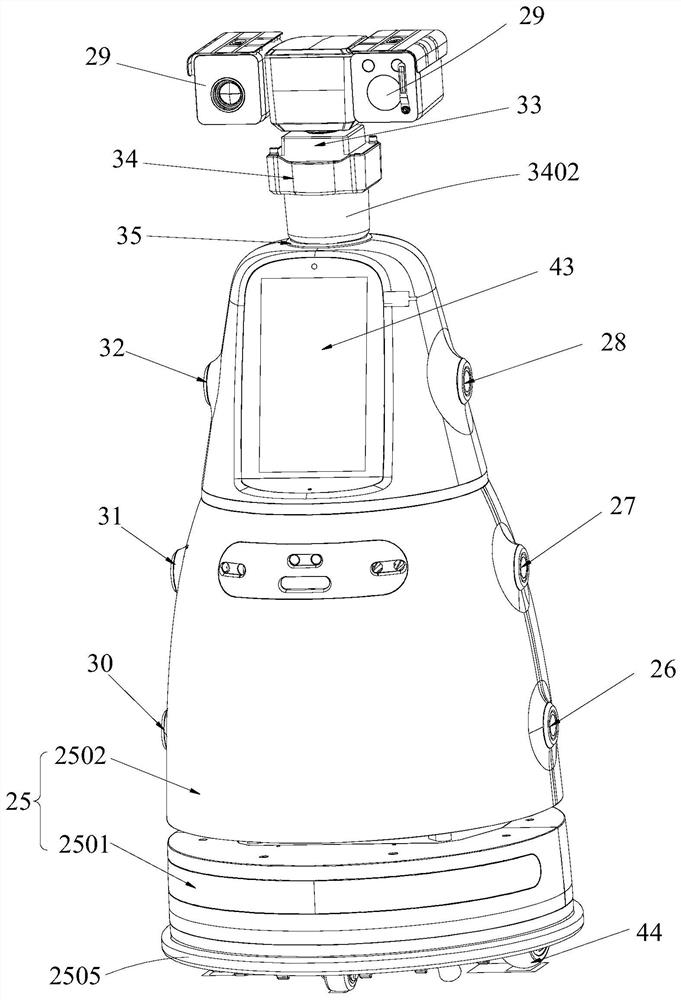

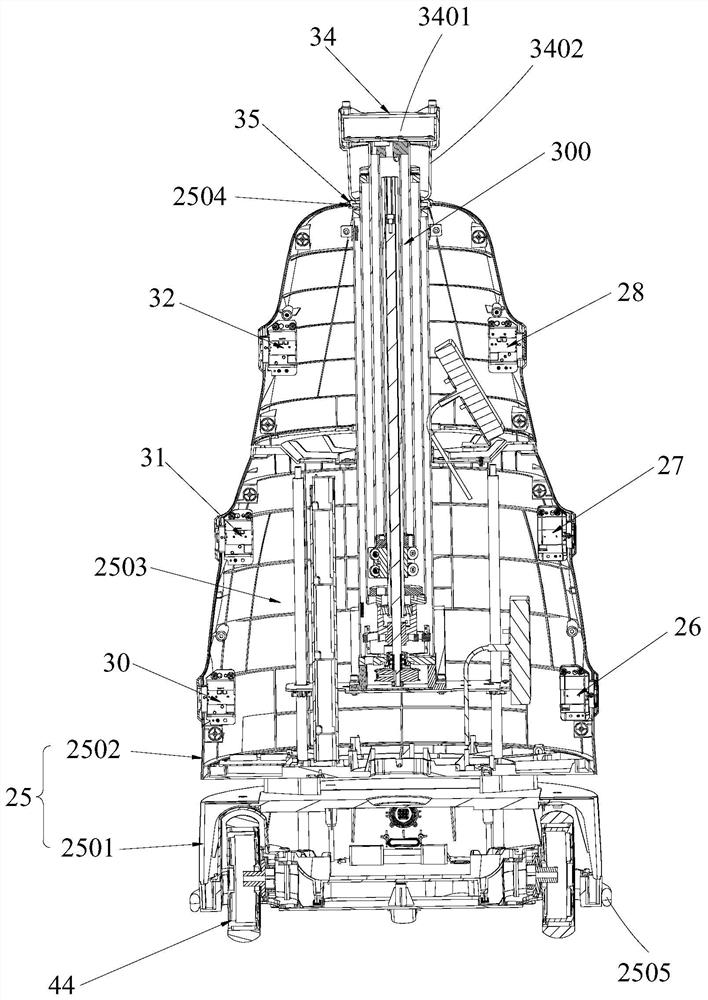

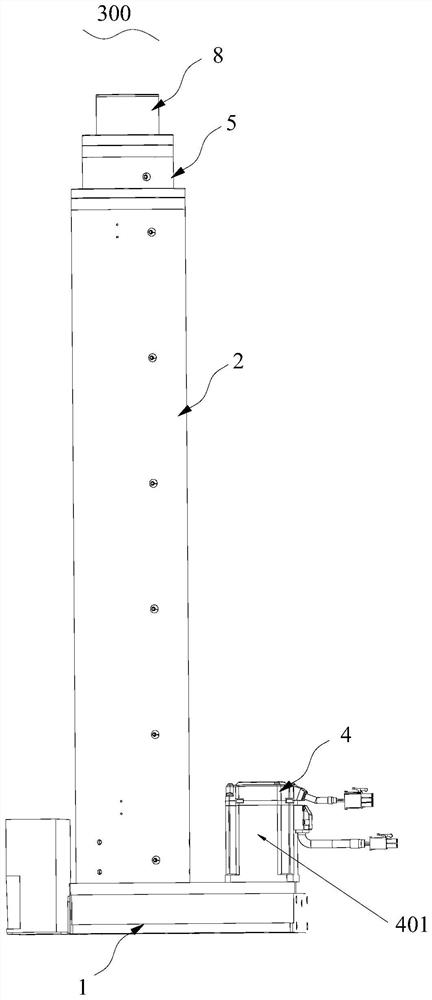

[0047] Further, see Figure 1-Figure 2 , as another specific embodiment of the inspection robot provided by the present application, a fixed frame 34 is provided between the lifting mechanism 300 and the cloud platform 33; the cloud platform 33 is connected to the output end of the lifting mechanism 300 through the fixed frame 34; the fixed frame 34 is provided with accommodating groove 3401; Cloud platform 33 is inserted in the containing groove 3401, can realize the fast installation of cloud platform 33; The barrel 3402 is sheathed on the outside of the lifting mechanism 300 , so that foreign matter from the outsi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com