Rejecting apparatus with automatic glass tube head clamping function

A technology of rejecting device and clamping device, which is applied in glass forming, glass reshaping, glass manufacturing equipment, etc. It can solve the problems of waste of glass tube raw materials, high degree of manual participation, waste discarding and labor, etc., so as to save work intensity , Improve work efficiency and reduce scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

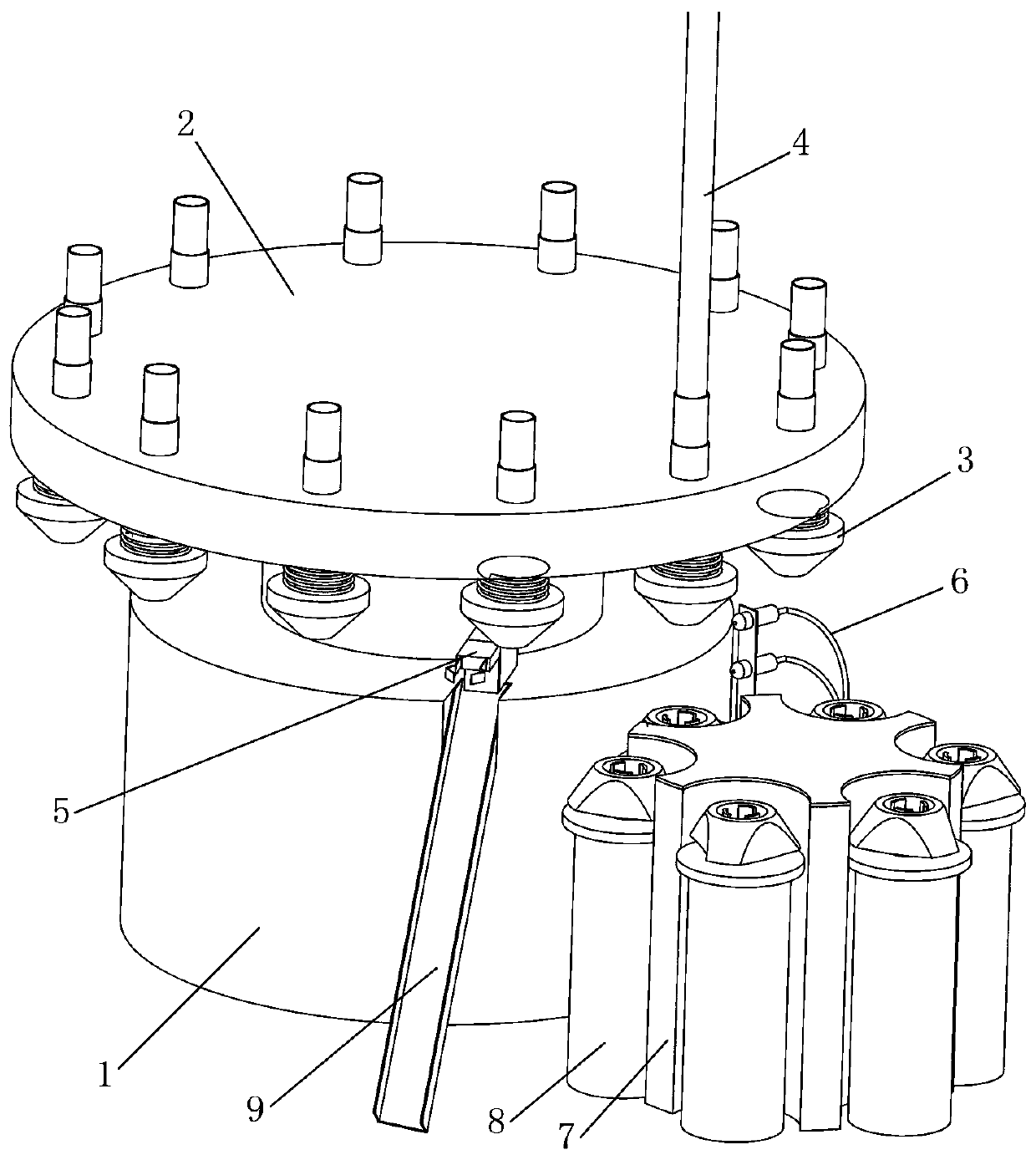

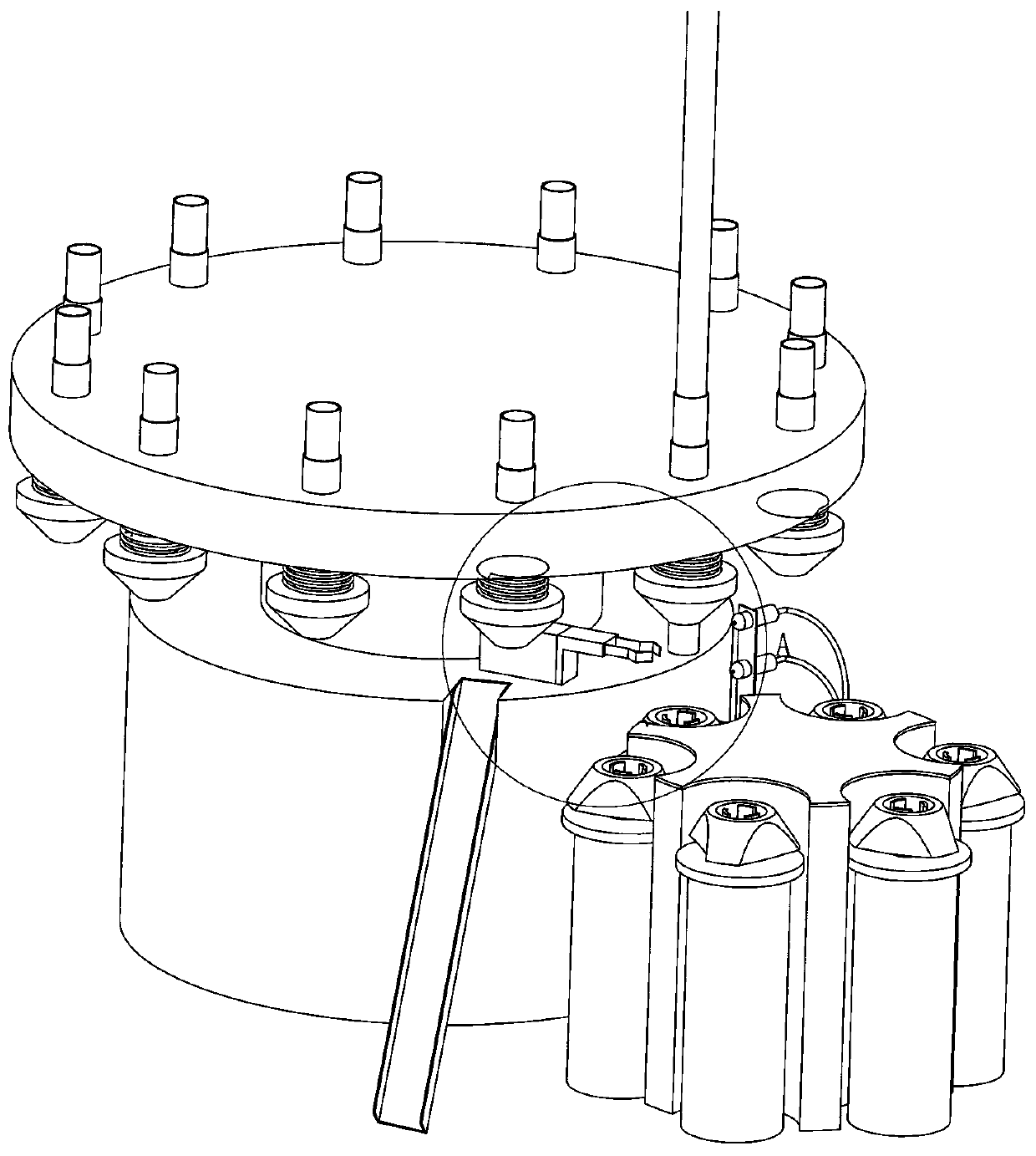

[0030] as attached Figure 1-17 As shown, the present invention includes a bottle making machine 1 and a finished glass tube collection device, the base 1, a turntable 2 arranged on the upper end of the base 1, and a tube lowering device 3 arranged on the turntable 2 on the circumference, and the finished glass tube collection device The finished product clamping device 8 arranged on the rotary table 7 and the circumference by the rotary table 7,

[0031] It is characterized in that it also includes an automatic clamping device, which is composed of a rotary rejecting device 5 and a detection control device 6,

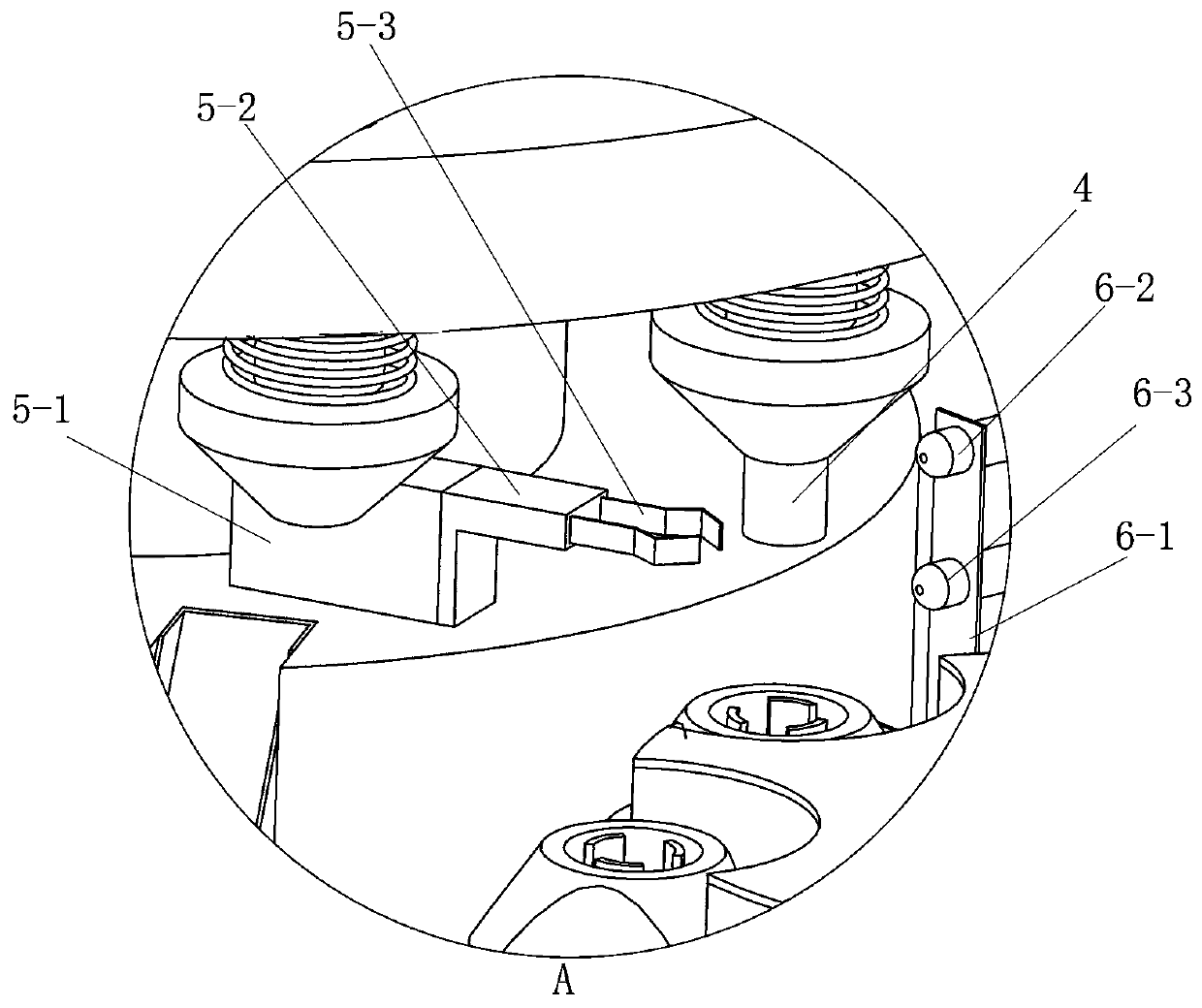

[0032] The automatic clamping device includes a rotating arm 5-1, a telescopic arm 5-2 arranged at the front end of the rotating arm 5-1, and a clamping claw 5-3 arranged at the front end of the telescopic arm 5-2, and the lower end is inserted into the In the base 1, the rear end of the telescopic arm 5-2 is inserted into the slide rail of the rotating arm 5-1, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com