Composite inorganic flame-retardant master batch and preparation method thereof

An inorganic flame retardant and inorganic flame retardant technology, which is applied in the field of flame retardant materials, can solve the problems of wide flame retardant temperature coverage, etc., and achieves convenient addition, good dispersibility and compatibility, and good compatibility and dispersibility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

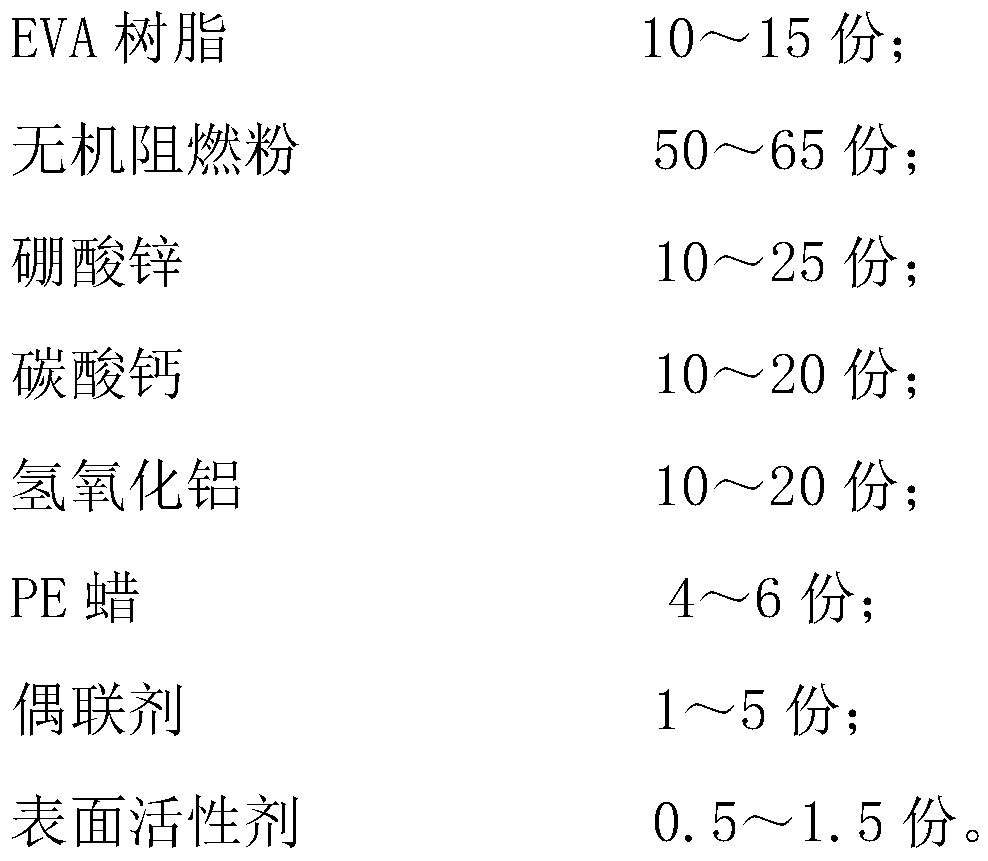

[0045] A composite inorganic flame retardant masterbatch, said masterbatch comprises in parts by weight:

[0046]

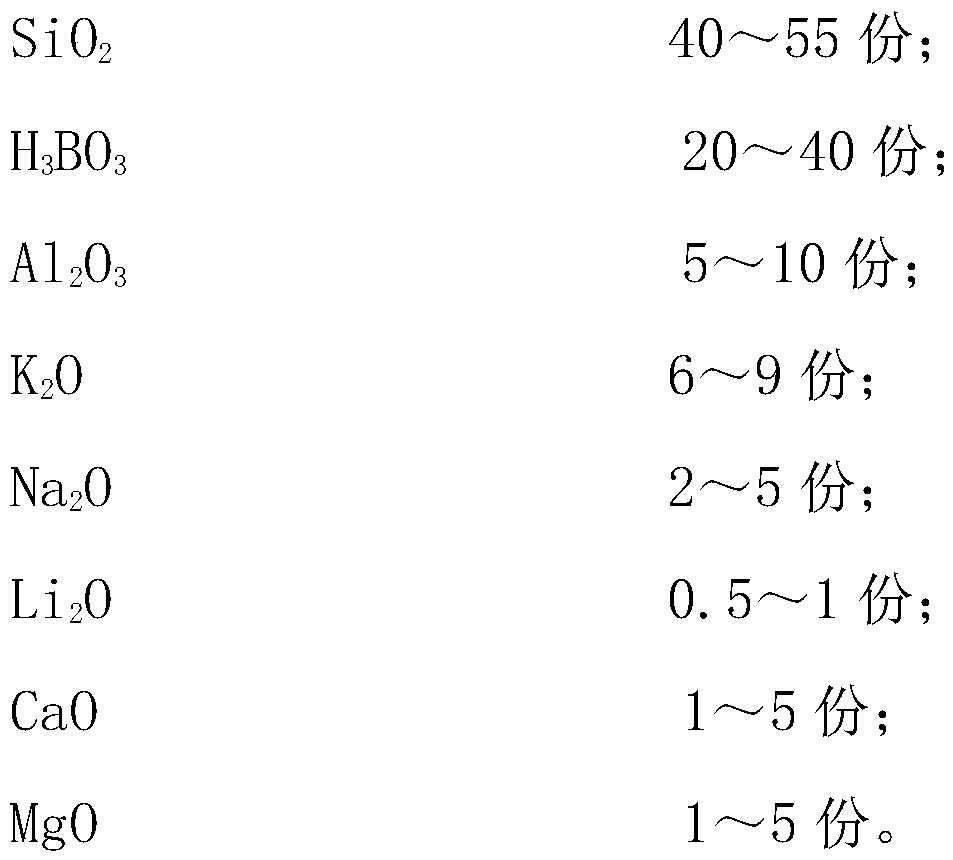

[0047] Described inorganic flame retardant powder comprises by weight parts:

[0048]

[0049] The preparation method of the inorganic flame retardant powder: take each component of the inorganic flame retardant powder according to the proportion, then put it into a high-temperature converter, melt it at 1400°C and then quench it to obtain a broken frit, and then grind the frit to obtain Inorganic flame retardant powder.

[0050] The preparation method of the composite inorganic flame retardant masterbatch comprises the following steps:

[0051] Step S1. Ultrafine treatment of the inorganic flame retardant: put the inorganic flame retardant powder into an ultrafine grinder for grinding, and sieve while grinding to obtain an ultrafine inorganic flame retardant powder with a particle size of less than 1250 mesh;

[0052] Step S2. Preparation of composite in...

Embodiment 2

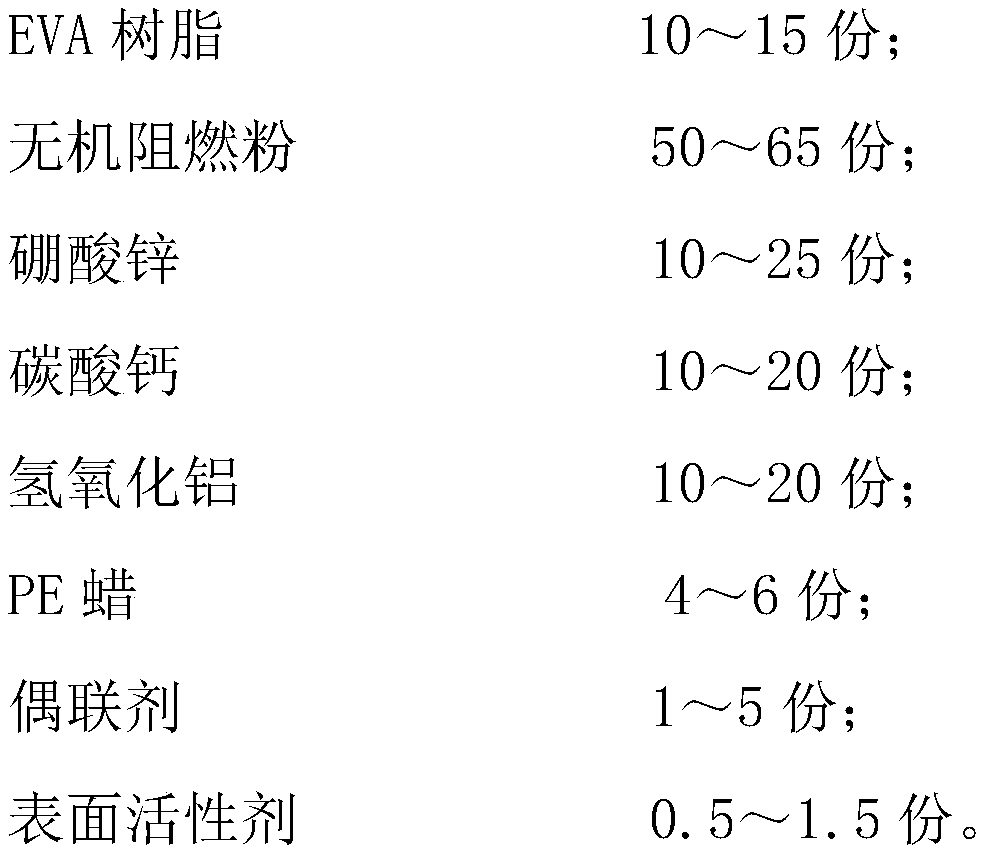

[0055] A composite inorganic flame retardant masterbatch, said masterbatch comprises in parts by weight:

[0056]

[0057]

[0058] Described inorganic flame retardant powder comprises by weight parts:

[0059]

[0060] The preparation method of the inorganic flame retardant powder is the same as that of Example 1, and the specific steps are shown in Example 1, except that the melting temperature is 1350°C.

[0061] The preparation method of the composite inorganic flame retardant masterbatch is the same as that of Example 1, and the specific steps are shown in Example 1, which will not be described in detail here.

Embodiment 3

[0063] A composite inorganic flame retardant masterbatch, said masterbatch includes by parts by weight:

[0064]

[0065]

[0066] Described inorganic flame retardant powder comprises by weight parts:

[0067]

[0068] The preparation method of the inorganic flame retardant powder is the same as that of Example 1, and the specific steps are shown in Example 1, except that the melting temperature is 1500°C.

[0069] The preparation method of the composite inorganic flame retardant masterbatch is the same as that of Example 1, and the specific steps are shown in Example 1, which will not be described in detail here.

[0070] The composite inorganic flame-retardant masterbatch prepared in Example 1-3 is used for the application test of flame-retardant performance, and the test is now carried out with 1000 parts by weight of PVC plastic substrate, and the addition amount of the flame-retardant masterbatch is 1000 parts, and other additives The conventional amount was add...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com