Electrolytic tin alloy plating solution

An electroplating tin and alloy technology, which is applied in liquid chemical plating, metal material coating process, coating, etc., can solve the problem that solder balls are difficult to meet the miniaturization requirements of semiconductor chips, and achieve the effect of suppressing the generation of voids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

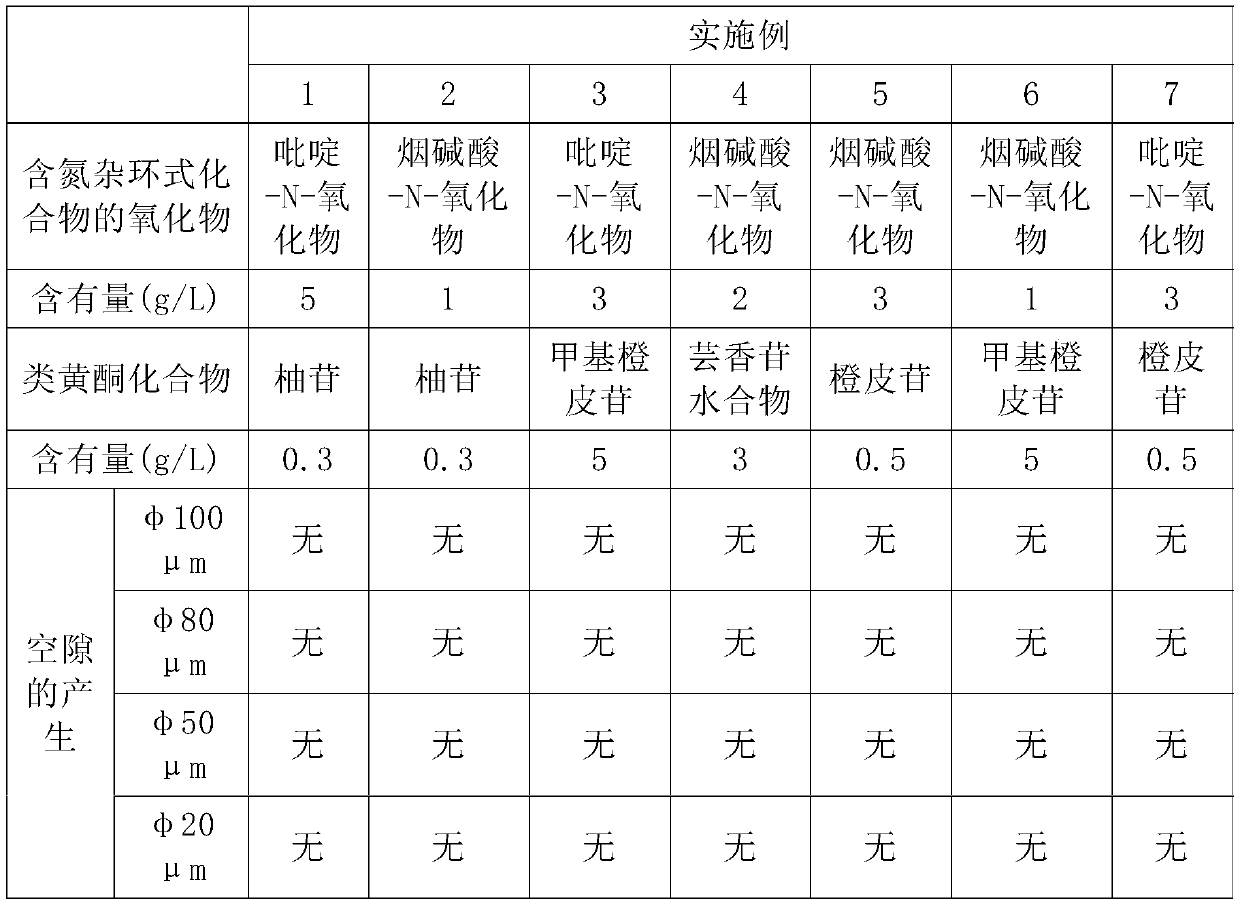

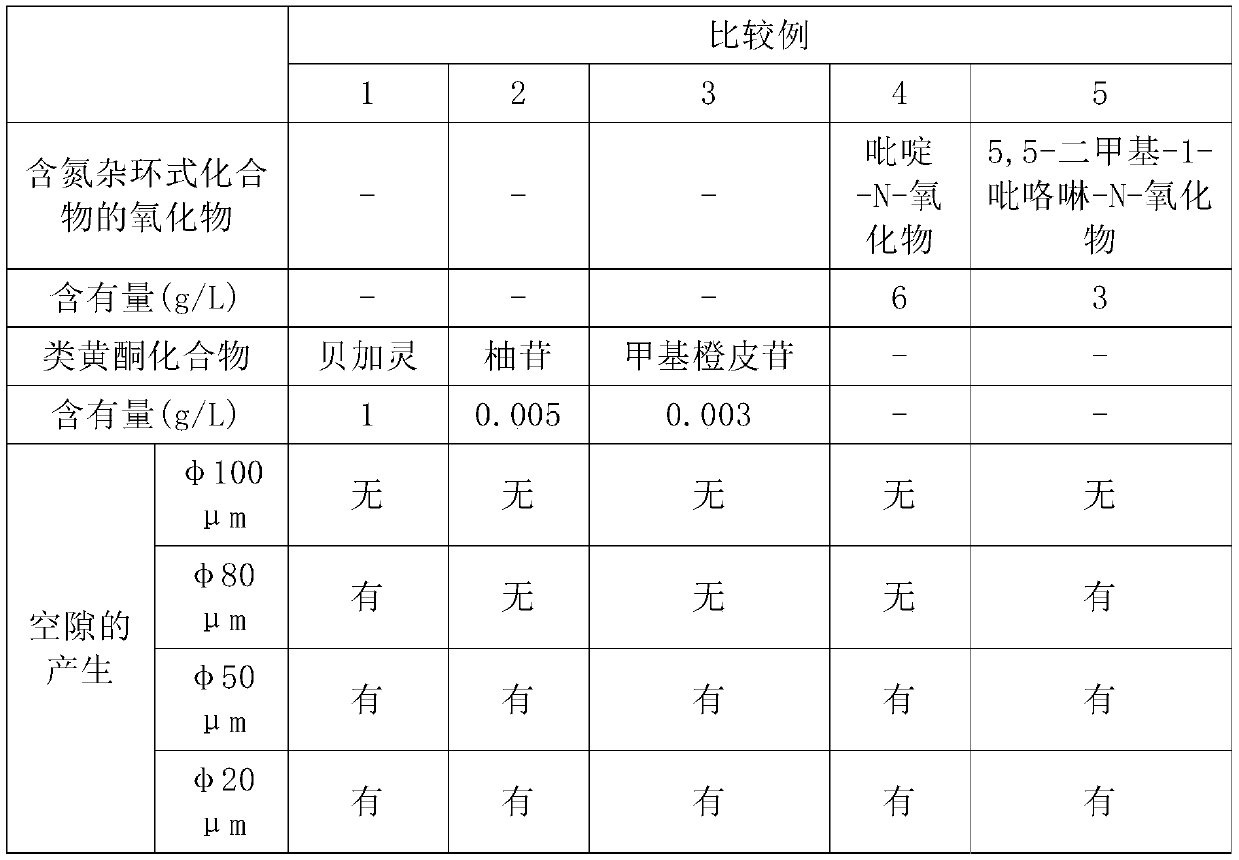

Examples

Embodiment 1

[0048] As the oxide of the nitrogen-containing heterocyclic compound, pyridine-N-oxide was used at a concentration of 5 g / L. The flavonoid compound uses naringin, the concentration is 0.3g / L. Adding tin(II) alkanesulfonate as a supply source of tin ions makes Sn 2+ The concentration of the meter reaches 60g / L, adding silver alkane sulfonate as a supply source of silver ions, so that Ag + to a concentration of 0.5 g / L, methanesulfonic acid as an organic acid was added to a concentration of 70 g / L, and a nonionic surfactant was added to a concentration of 20 g / L. The bath temperature is 30°C and the current density is 4A / dm 2 .

[0049] In the case of either pad diameter, no voids were observed in the bumps composed of the resulting tin-silver alloy plating films after reflow.

Embodiment 2

[0051] Except that nicotinic acid-N-oxide was used as the oxide of the nitrogen-containing heterocyclic compound and the concentration was 1 g / L, other aspects were the same as in Example 1, and a tin-silver alloy coating was formed in this way. In the case of either pad diameter, no voids were observed in the bumps composed of the resulting tin-silver alloy plating films after reflow.

Embodiment 3

[0053] Except that the oxidation of the nitrogen-containing heterocyclic compound uses 3g / L of pyridine-N-oxide, and the flavonoid compound uses 5g / L of methyl hesperidin, other aspects are all the same as in Example 1, thus forming tin silver Alloy coating. In the case of either pad diameter, no voids were observed in the bumps composed of the resulting tin-silver alloy plating films after reflow.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com