Process for manufacturing semiconductor device and semiconductor device manufactured by such process

A semiconductor and device technology, which is applied to the process of manufacturing semiconductor devices and the field of semiconductor devices manufactured by this process, can solve problems such as preventing voids, and achieve the effect of preventing quality degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

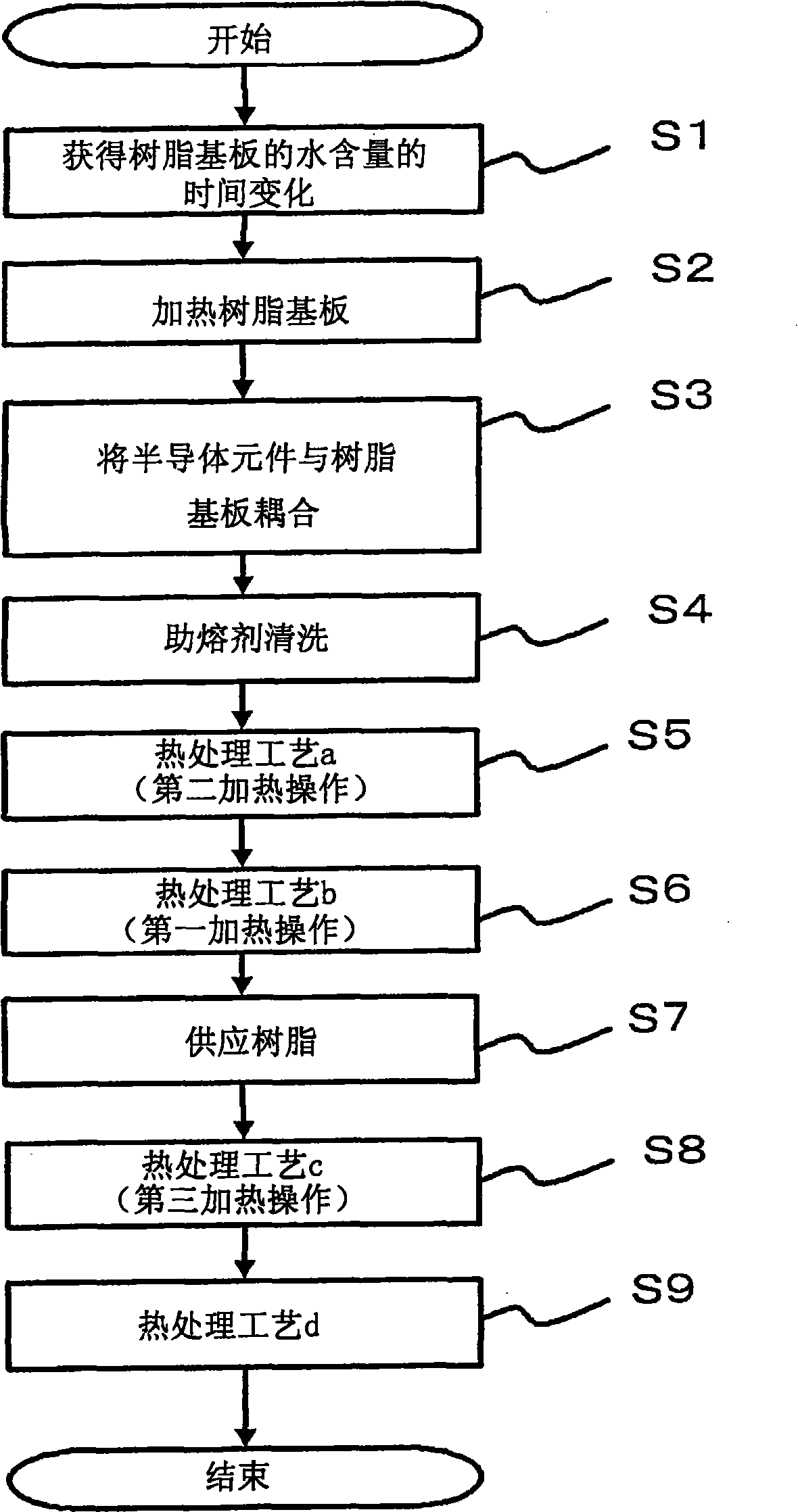

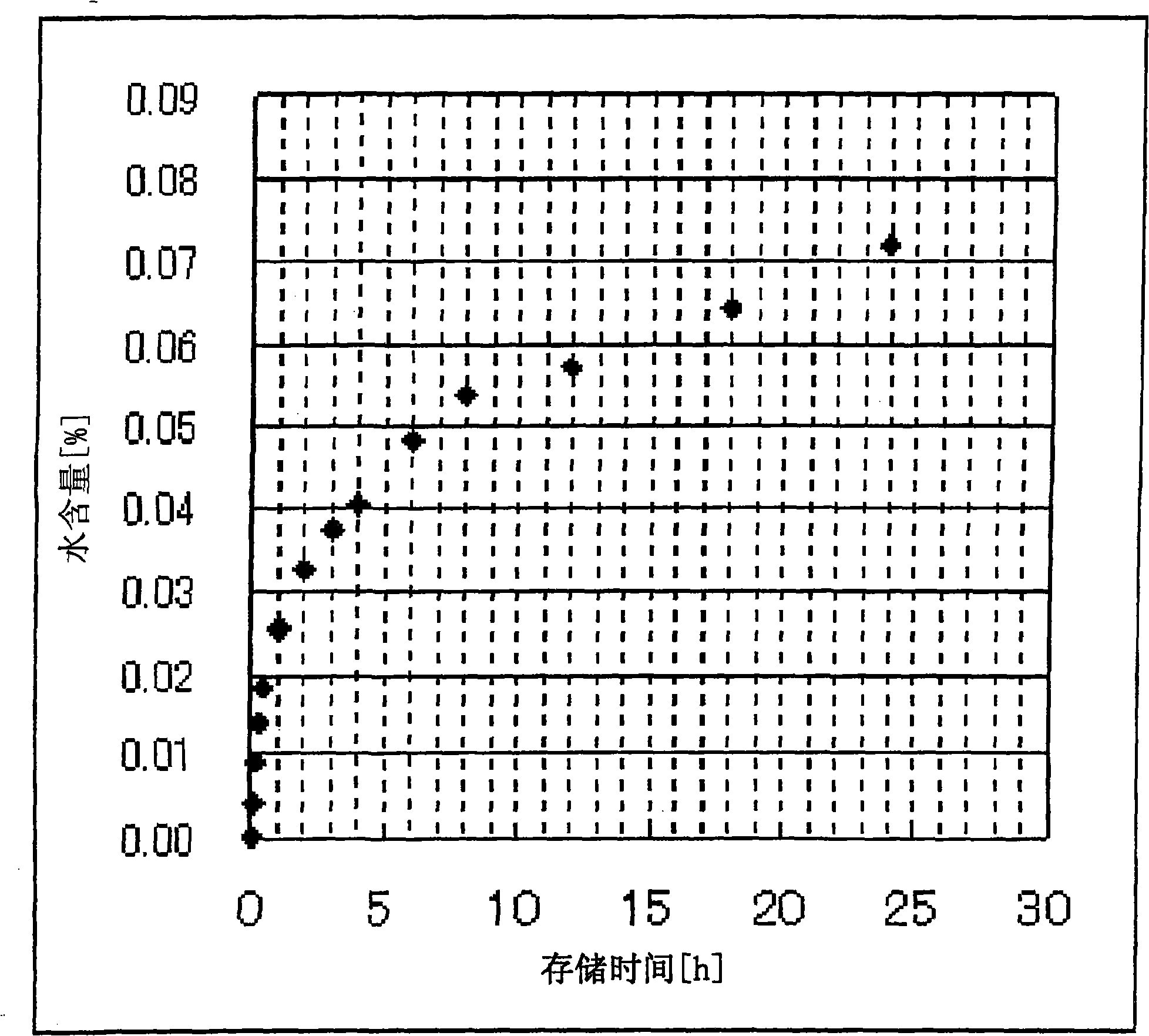

[0063] Next, similarly to the above-described embodiment, a semiconductor element is mounted on the resin substrate, and processing S2 to processing S5 are performed. The bump pitch (inter-bump distance) of the bumps for coupling the semiconductor element and the resin substrate was 169 μm. The solder portion of the resin substrate and the above-mentioned bumps are made of lead-free solder (more specifically, Sn 3 Ag 0.5 Cu) composition. Thereafter, the substrate was left in the clean room for 480 minutes at a temperature of 22.5° C. and a humidity of 50%. according to image 3 and 4 , the water content of the substrate at this time was considered to be 0.055%. Next, the semiconductor device was set in a heating device (the periphery of the heating unit (hot plate) was opened to atmospheric air) at a temperature of 95° C., and then taken out after 150 seconds. In this case, the water content of the resin substrate was 0.02% ( Figure 5 ). The resin was supplied (underf...

example 2

[0065] Similar to Example 1, a semiconductor device having a resin substrate having a water content of 0.055% was installed in a heating device, and taken out after 330 seconds. At this time, the water content of the substrate was 0.017%. The resin was supplied within 3 minutes after the substrate was taken out from the heating apparatus. Since the supply of the resin was started within 3 minutes, the water content of the resin substrate was considered to be 0.017%. Then, the resin was cured similarly to Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com