Construction method and structure for partially replacing row pile support based on cutter suction type diaphragm wall

A ground-to-wall and twist-suction technology, which is applied in foundation structure engineering, excavation, sheet pile walls, etc., can solve problems such as the inability to close the foundation pit, the inability to relocate the pipeline, and the large diameter or width of the pipeline, so as to broaden the design ideas , high economic and social benefits, and wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in combination with specific embodiments.

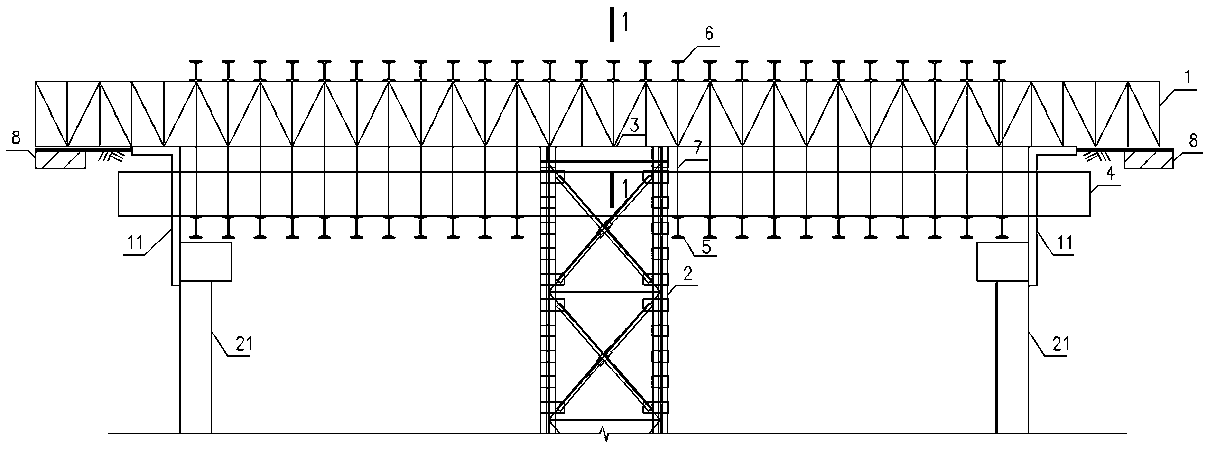

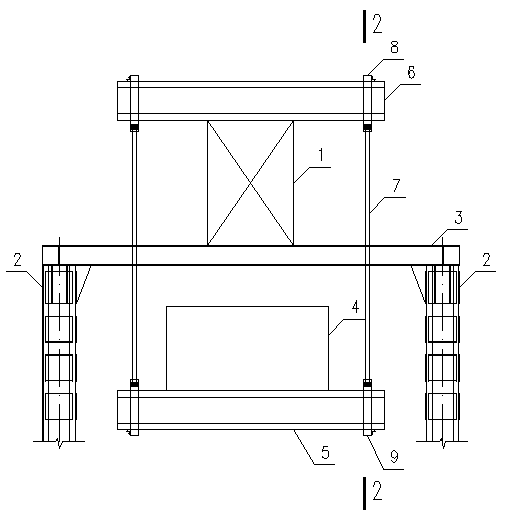

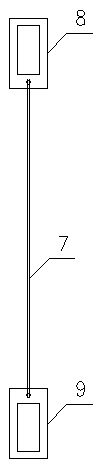

[0030] The invention relates to a construction structure based on a twisted-suction ground connection wall partially replacing row pile support, including a pipeline suspension protection structure and a steel cage outside the pipeline. The pipeline suspension protection structure includes lattice columns 2 on both lateral sides of the pipeline 4, a horizontal I-shaped steel platform 3 is arranged on the top of the lattice column 2, a vertical steel truss 1 is arranged above the I-shaped steel platform 3, and a vertical steel truss 1 is arranged above the steel truss 1. The upper I-beams 6 arranged in parallel in the longitudinal direction are arranged, and the lower I-beams 5 located under the pipeline 4 are suspended on both lateral sides of the upper I-beams 6 through the upper hanging parts 8, the upper chains 7 and the lower hanging parts 9. 4 is located above the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com