Asynchronous motor frame

A technology of electric motors and machine bases, applied in the field of electric motors, can solve problems such as failure to solve temperature rise control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

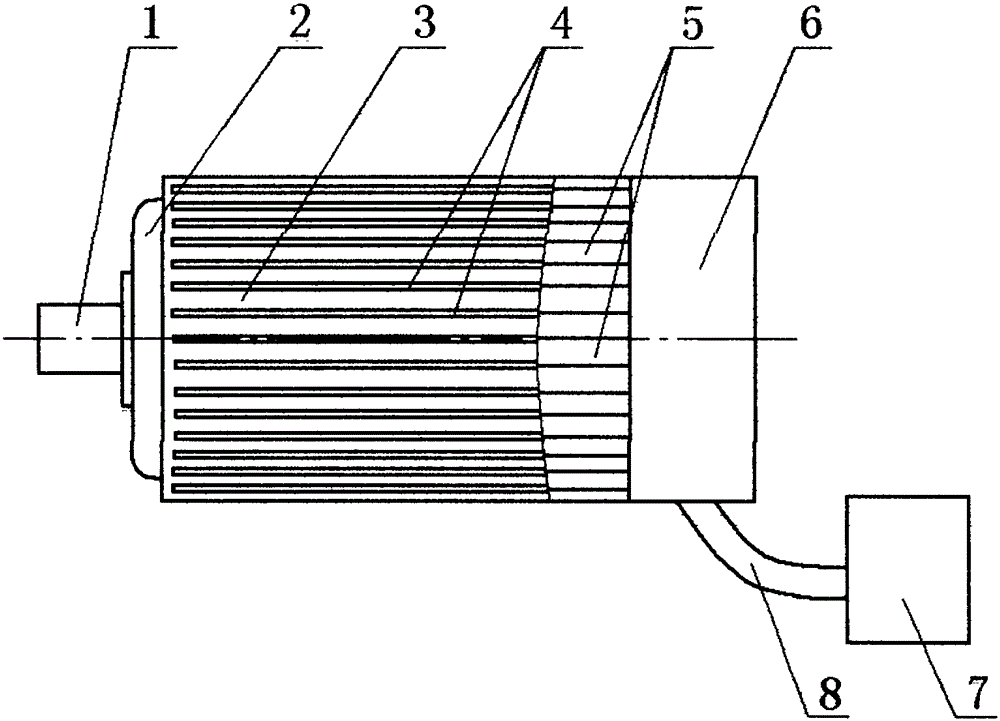

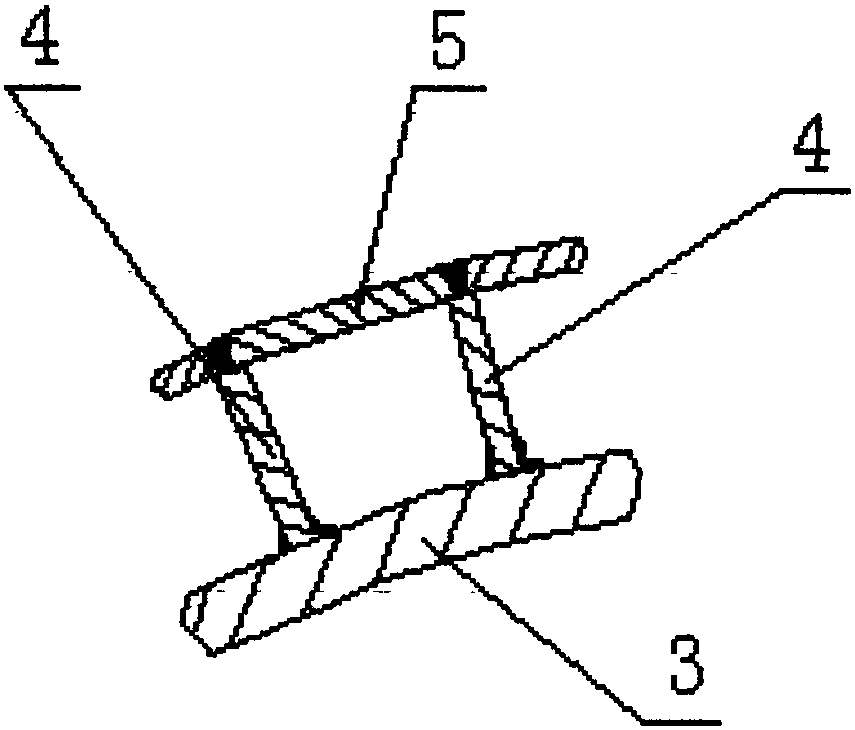

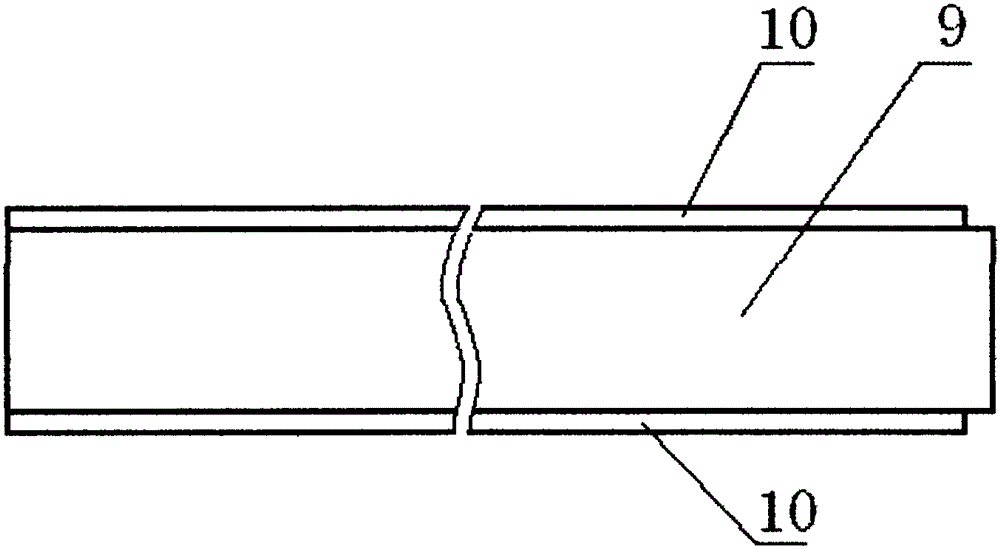

[0013] like figure 1 , figure 2 , image 3 As shown, an asynchronous motor cooling device includes a blower mechanism 7, a wind cover 6, a base body 3 and a front end cover 2 close to the motor output shaft 1, the wind cover 6 is located at one end of the base body 3, and the front cover 2 is located at the end of the machine base body. On the other end of the base body 3, the blower mechanism 7 communicates with the wind cover 6. There are a plurality of cooling ribs 4 on the base body 3, and each cooling rib 4 is parallel to the axis of the motor output shaft 1. Every two adjacent cooling ribs The top ends of the ribs 4 are provided with integrated strip plates 5 , and the machine base body 3 , multiple cooling ribs 4 and multiple strip plates 5 form a tubular channel with a special-shaped cross section. The frame body 3, the front end cover 2, the cooling rib 4, the strip plate 5 and the wind cover 6 are parts of the asynchronous motor frame respectively, and the strip p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com