Pattern weave, two-layer or multi-layer cloth and weaving process of two-layer or multi-layer cloth

A weaving and patterning technology, applied in textiles, papermaking, fabrics, textiles, etc., can solve the problems of hard hand feeling without bulkiness, heavy and poor ventilation performance, thin products, etc., to achieve product design with clear layers, rich, soft and fluffy, three-dimensional Obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Yarn selection: warp beam 40s / 2 ply yarn, weft yarn 21s / 1 single yarn

[0032] The weaving process is as follows:

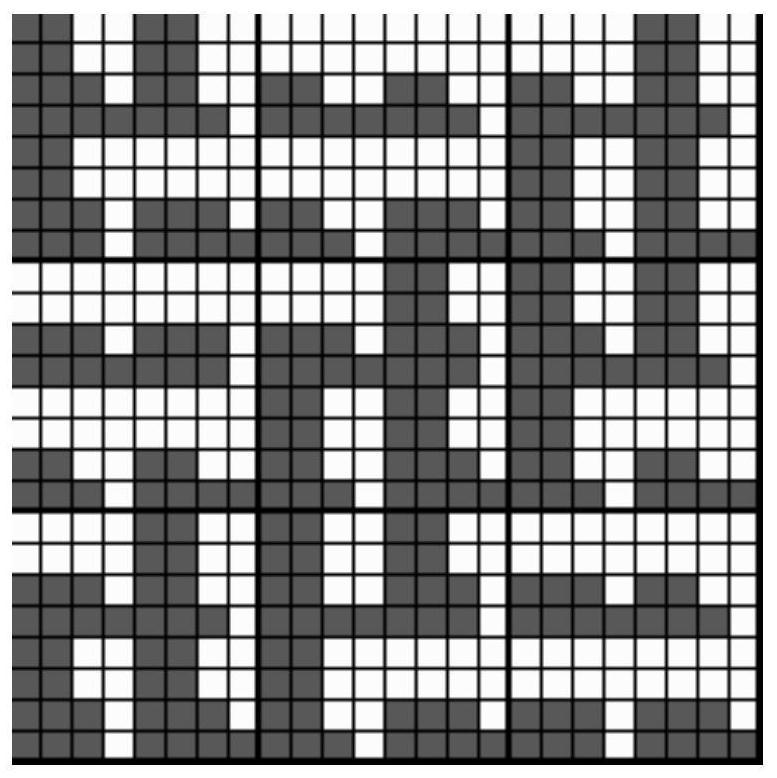

[0033] Such as figure 1 and figure 2 As shown, the warp and weft are divided into 4 parts, the warp is defined as zone 1, zone 2, zone 3, and zone 4, and the weft is defined as shuttle 1, shuttle 2, shuttle 3, and shuttle 4. From left to right, there are zone 1, zone 2, zone 3 and zone 4. The weft yarns are 1 shuttle, 2 shuttle, 3 shuttle and 4 shuttle from top to bottom. The shuttle weaving method is used for product weaving.

[0034] The pattern layer uses 3 upper and 3 lower variable twill weaves as the basic weave, the pattern layer occupies the warp yarns in zone 1 and zone 2, the weft yarn occupies the 1 shuttle position and the 2 shuttle position, and the middle 3 layers use plain weave as the basic structure to occupy the warp yarn and 3 shuttle positions in zone 3 The lower surface is based on plain weave and occupies 4 zones of warp and 4 sh...

Embodiment 2

[0037] Yarn selection: warp beam 40s / 2 strands, weft 40s / 2 strands

[0038] Weaving process:

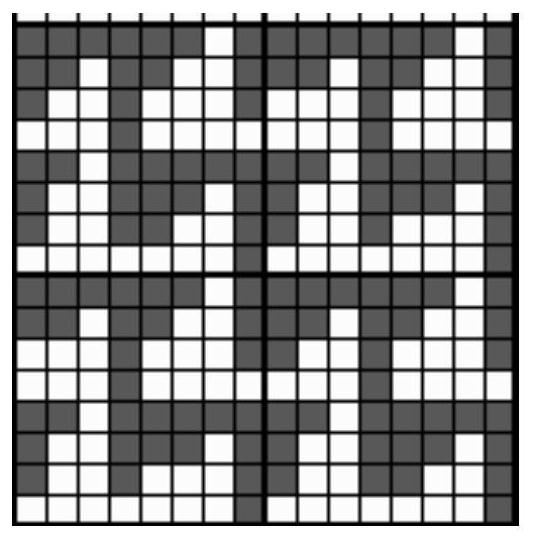

[0039] Such as image 3 and Figure 4 As shown, the warp and weft yarns are divided into 4 parts. The warp yarns are respectively defined as zone 1, zone 2, zone 3 and zone 4. The weft yarns are respectively defined as 1 shuttle, 2 shuttles, 3 shuttles and 4 shuttles. The mode of entering heddle and 4 reeds is used to draw out heddles and enter the reed, and the mode of 4 shuttle weaving is used for product weaving.

[0040] The pattern layer adopts the combined weave pattern to form the pattern layer, and the weave pattern is arranged in staggered angles with 6 upper and 6 lower left twill patterns and 6 upper and 6 lower right twill patterns. 2 shuttle positions, the middle 2 layers use plain weave as the basic weave to form 3 warp zones and 3 shuttle positions, and the lower surface layer uses plain weave as the basic weave to occupy 4 zone warp yarns and 4 shuttle positions to...

Embodiment 3

[0042] Yarn selection: warp beam 40s / 2 strands, weft 40s / 2 strands

[0043] Weaving process:

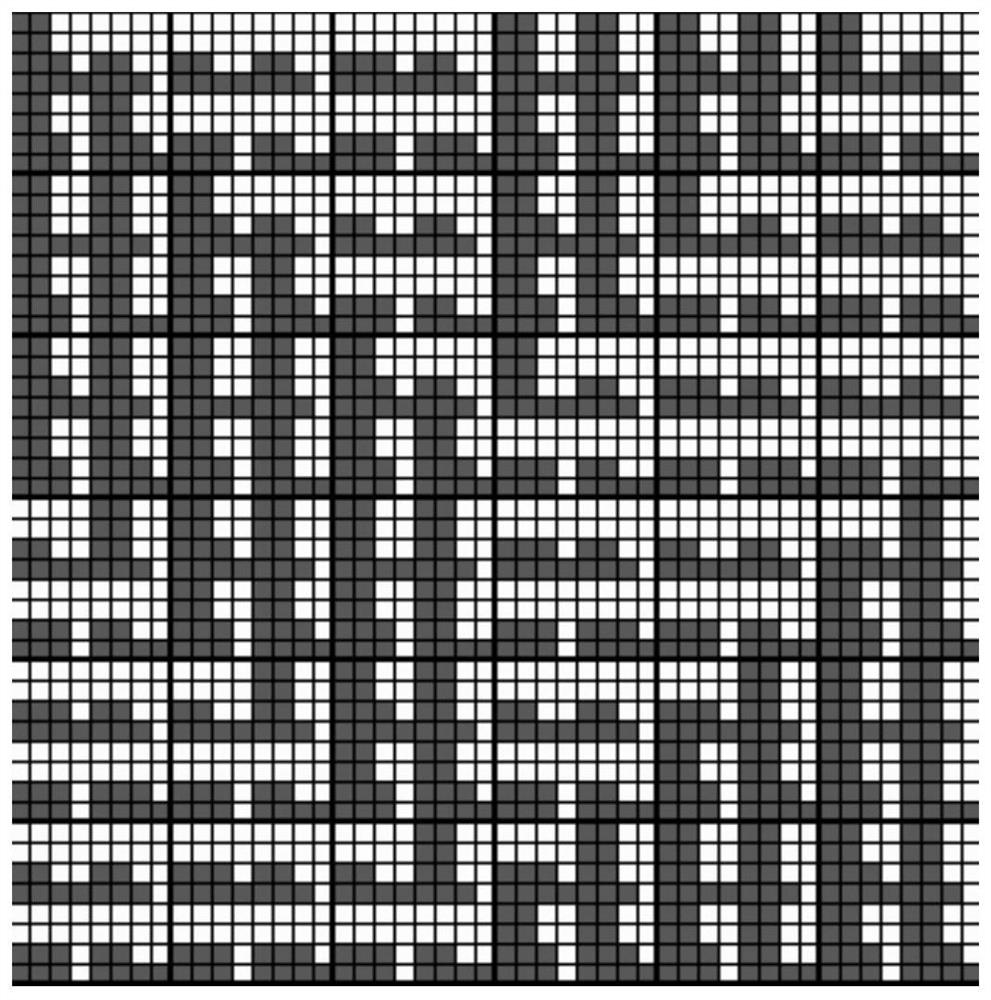

[0044] Such as Figure 5 and Figure 6 As shown, the warp and weft yarns are divided into 3 parts, and the warp yarns are respectively defined as zone 1, zone 2, and zone 3, and the weft yarns are defined as 1 shuttle, 2 shuttles, and 3 shuttles respectively, and the method of 1 heald and 3 reeds is adopted Carry out comprehensive reed, 3-shuttle weaving mode for product weaving.

[0045] The pattern layer adopts overlapping honeycomb pattern to form the pattern layer. The pattern layer occupies the warp yarns in zone 1 and zone 2, and the weft yarn occupies 1 shuttle position and 2 shuttle positions. And the pattern layer is combined with 3 layers of gauze technology to form a pattern.

[0046] Among them, the above-mentioned embodiment 1 and embodiment 2 adopt the technological process of dyeing first and then weaving: yarn reactive dyeing-warping-machine weaving-grain fabric d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com